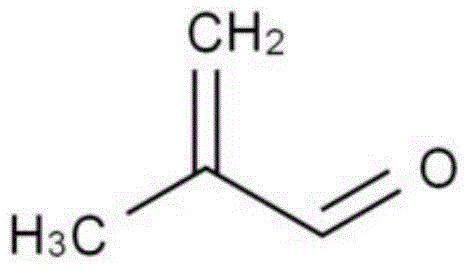

Synthetic process of methylacrolein

A technology of methacrolein and synthesis process, which is applied in the preparation of carbonyl compounds, the separation/purification of carbonyl compounds, the preparation of organic compounds, etc. It can solve problems such as the inability to balance rate and selectivity, and achieve the effect of solving potential dangers, harsh solution conditions and high utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

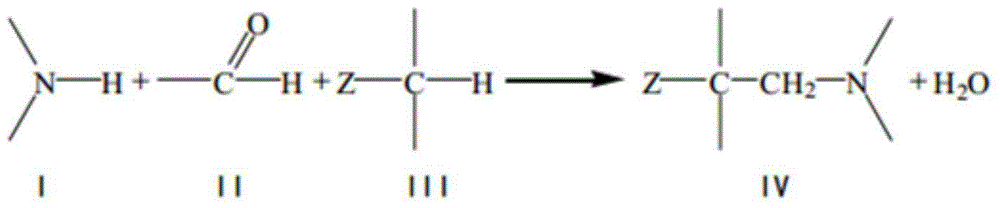

Method used

Image

Examples

Embodiment 1

[0023] A method for synthesizing methacrolein, using paraformaldehyde and propionaldehyde to synthesize methacrolein under the condition of morpholine hydrochloride as a catalyst.

[0024] The specific operation steps of the synthesis process are as follows: add an appropriate amount of paraformaldehyde to the morpholine hydrochloride solution, raise the temperature to 80°C to completely dissolve the paraformaldehyde in the solution, and then lower the temperature, drop an appropriate amount of propionaldehyde into the above solution. The adding temperature is stabilized at a certain temperature. After all propionaldehyde is dropped into the solution, it is heated to 50-60°C for reaction. After the gas phase detection reaction is over, the temperature is raised to 67-110°C for atmospheric distillation, and the distilled product is allowed to stand for stratification. , The separated oil phase is methacrolein, and the separated water phase is returned to the reaction system for rec...

Embodiment 2

[0032] The synthesis process of Example 1 was used to synthesize methacrolein, in which the weight ratio of morpholine hydrochloride solution and propionaldehyde was 3-5, and 3 control examples were set up, respectively, the dripping temperature of propionaldehyde was 15-35℃, 35 -40℃, 40-50℃, respectively number the methacrolein synthesized at different dropping temperature as Ⅰ, Ⅱ, and Ⅲ. The products obtained after the reaction were sampled and detected by LC / MS to obtain the methacrolein Yield, selectivity, purity, experimental data are shown in Table 2.

[0033] Table 2 Test results of dimethyl acrolein products in Example

[0034] Yield (%) Selectivity (%) purity(%) Ⅰ97.799.998.4 Ⅱ98.799.999.2 Ⅲ 97.299.597.3

[0035] From the above experimental data, it can be seen that the yields of groups I-III are all above 97%, the purity is above 97%, and the selectivity is above 99%, which is close to 100%. Therefore, it can be seen that the synthesis of the technical scheme of th...

Embodiment 3

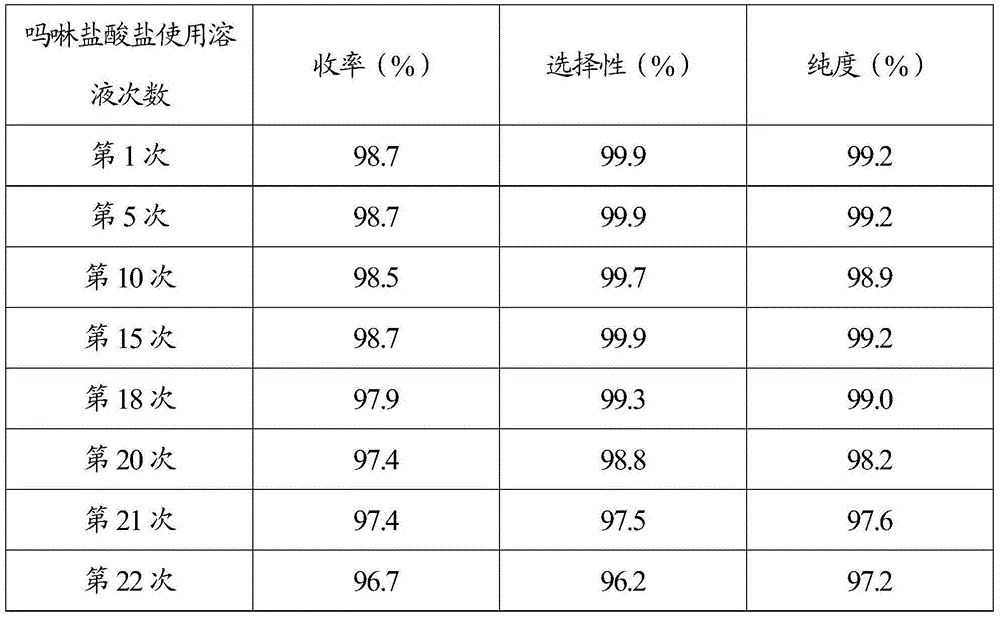

[0037] Synthesize methacrolein using the synthesis process of Example 1, wherein the weight ratio of morpholine hydrochloride solution and propionaldehyde is 3-5, and the temperature of propionaldehyde dropping is 35-40℃, and the residue in the kettle after atmospheric distillation The morpholine hydrochloride solution was used as the catalyst for the next reaction to be recycled 22 times. Before the next cycle, the pH value was adjusted to 2-3, and the products obtained after each reaction were sampled and tested by LC / MS. The yield, selectivity and purity of methacrolein are obtained. The experimental data are shown in Table 3.

[0038] Table 3 Test results of trimethacrolein products in Example

[0039]

[0040] From the above data, it can be seen that before the morpholine hydrochloride solution was used 22 times, the yield of methacrolein was above 97%, and the purity was above 97%. However, the indicators began to decrease from the 22nd test. It can be seen that the morpholi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com