Method for producing nicotinic acid by using nicotinamide mother solution

A technology using nicotinamide mother and nicotinamide mother, which is applied in the direction of organic chemistry, can solve the problems of high impurity content of nicotinamide, poor quality of nicotinamide, quantity loss, etc., and achieve maximum benefit, simplified production process, energy consumption reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

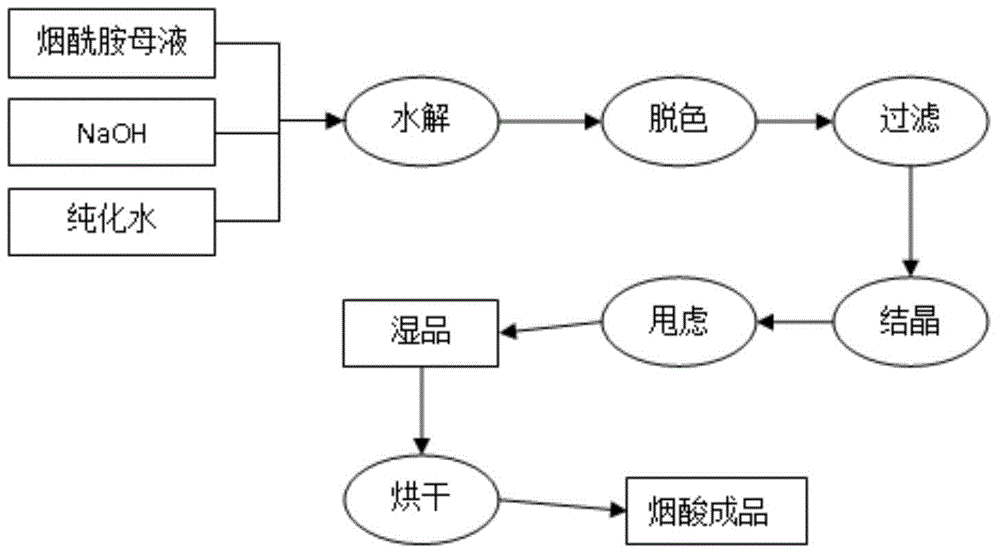

[0032] A method for producing nicotinic acid using nicotinamide mother liquor, comprising the following preparation steps,

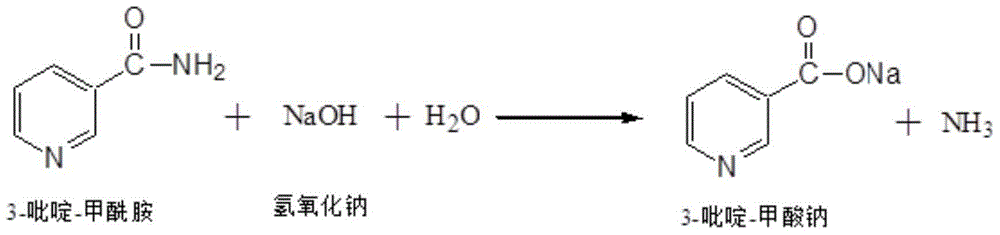

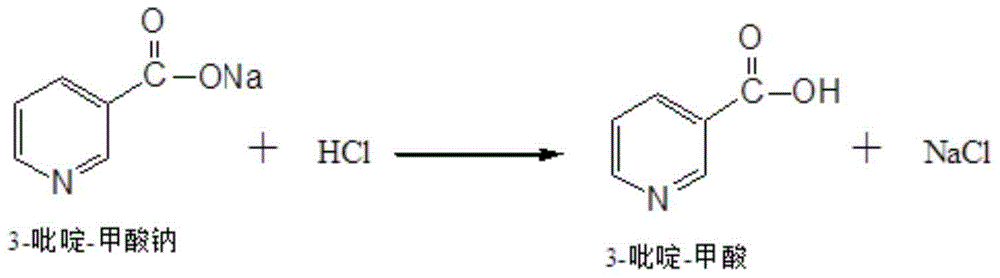

[0033] 1), hydrolysis reaction

[0034] Weigh 450g of nicotinamide mother liquor, wherein the mass concentration of nicotinamide in nicotinamide mother liquor is 28.0%, put nicotinamide mother liquor and caustic soda into a four-necked bottle, and then use a graduated cylinder to measure a certain amount of purified water into the four-necked bottle, The mass ratio of nicotinamide, sodium hydroxide and purified water in the four-necked bottle is 1:0.80:4; start stirring and start heating, when the temperature rises to 108°C, start timing, the temperature is controlled at 108-115°C, and the reaction time For 3 hours, during the hydrolysis reaction, add an appropriate amount of purified water to ensure that the volume of the liquid in the four-necked bottle does not change, and obtain 3-pyridine-sodium formate after the hydrolysis reaction;

[0035] 2), d...

Embodiment 2

[0045] A method for producing nicotinic acid using nicotinamide mother liquor, comprising the following preparation steps,

[0046] 1), hydrolysis reaction

[0047] Weigh 450g of nicotinamide mother liquor, wherein the mass concentration of nicotinamide in nicotinamide mother liquor is 28.0%, put nicotinamide mother liquor and caustic soda into a four-necked bottle, and then use a graduated cylinder to measure a certain amount of purified water and drag it into the four-necked bottle , the mass ratio of nicotinamide, sodium hydroxide and purified water in the four-necked bottle is 1:0.6:4; start stirring and start heating, when the temperature rises to 105°C, start timing, control the temperature at 105-112°C, and react The time is 2.5 to 3.5 hours. During the hydrolysis reaction, add an appropriate amount of purified water to ensure that the volume of the liquid in the four-necked bottle does not change. After the hydrolysis reaction, 3-pyridine-sodium formate is obtained;

...

Embodiment 3

[0059] A method for producing nicotinic acid using nicotinamide mother liquor, comprising the following preparation steps,

[0060] 1), hydrolysis reaction

[0061] Weigh 450g of nicotinamide mother liquor, wherein the mass concentration of nicotinamide in nicotinamide mother liquor is 28.0%, put nicotinamide mother liquor and caustic soda into a four-necked bottle, and then use a graduated cylinder to measure a certain amount of purified water and drag it into the four-necked bottle , the mass ratio of nicotinamide, sodium hydroxide and purified water in the four-necked bottle is 1:0.40:4; start stirring and start heating, when the temperature rises to 102°C, start timing, control the temperature at 102-108°C, and react The time is 3 hours. During the hydrolysis reaction, an appropriate amount of purified water is added to ensure that the volume of the liquid in the four-necked bottle does not change, and 3-pyridine-sodium formate is obtained after the hydrolysis reaction;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com