Terpolymer carrier and preparation method thereof

A terpolymer and carrier technology, applied in the field of terpolymer and its preparation, can solve the problems of uncontrollable particle specific surface area and average pore size, unfavorable metallocene catalyst loading, small particle size of polymer particles, etc. Uniform size, low inorganic ash content, narrow dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

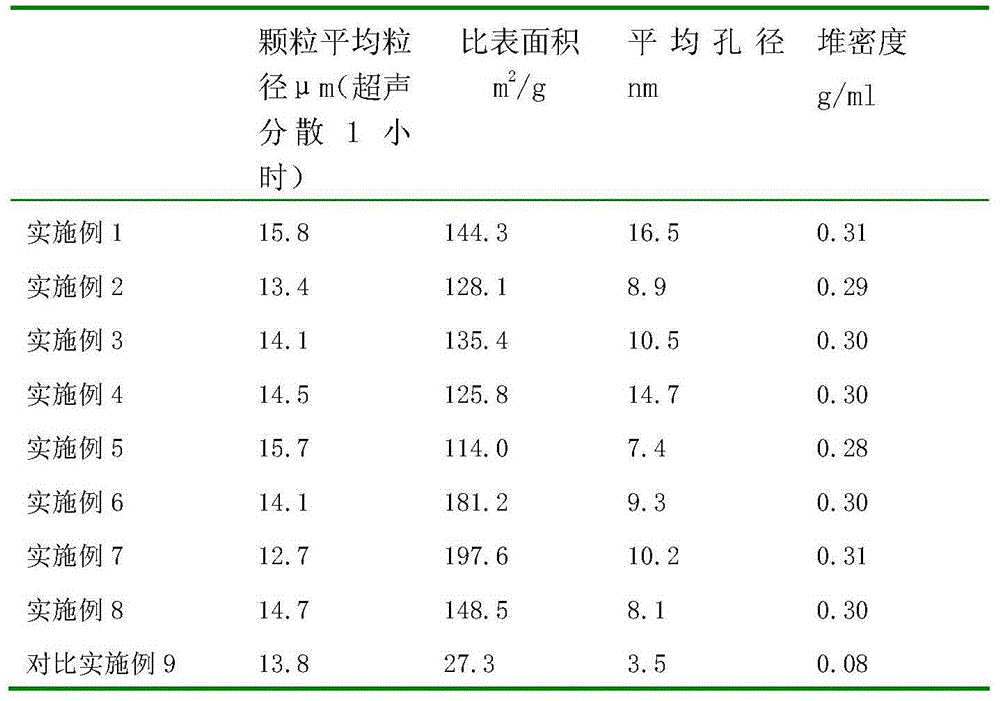

Examples

Embodiment 1

[0018] Comonomer treatment: use 10% NaOH solution to remove the polymerization inhibitor before use of styrene and divinylbenzene, and then use it after washing 3 times with deionized water; use neutral oxidation for ethylene glycol dimethacrylate The aluminum chromatographic column was used after removing the polymerization inhibitor. The following examples do not specifically illustrate that the comonomers are used after treatment.

[0019] Preparation of organic porous support: In a 250ml glass reactor, add 150ml ethanol and 15ml deionized water, then add 8ml (about 7.4g) styrene, 8ml 55% (about 7.5g) divinylbenzene and 5ml dimethyl Ethylene glycol acrylate (about 4.8g), stirred at room temperature for 5 minutes, then added 2% polyvinyl alcohol (polymerization degree: 1750) of monomer mass at 45°C, stirred for 1 hour to dissolve the polyvinyl alcohol stabilizer, Then add 10ml DNBP and 1.5% AIBN of monomer mass, raise the temperature to 70°C, react for 3 hours, then raise t...

Embodiment 2

[0021] Preparation of organic porous support: In a 250ml glass reactor, add 108ml ethanol and 12ml deionized water, then add 4ml (about 3.9g) styrene, 4ml 55% (about 3.7g) divinylbenzene and 2ml dimethyl Ethylene glycol acrylate (about 2.0g), stirred at room temperature for 5 minutes, then added 2% polyvinyl alcohol (polymerization degree: 1750) of monomer mass at 45°C, stirred for 1 hour to dissolve the polyvinyl alcohol stabilizer, Then add 4ml DNBP and 1.5% AIBN of monomer mass, raise the temperature to 70°C, react for 3 hours, then raise the temperature to 80°C, react for 5 hours, stir at 600 rpm, wash with ethanol 3 times, and dry Finally, a porous organic carrier is obtained.

Embodiment 3

[0023] The preparation of the organic porous carrier in Example 3 is the same as in Example 2 except that the amount of porogen used is different, and the preparation steps are the same as the amount of other reagents. In Example 3, 7ml DNBP was added instead of 4ml DNBP.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com