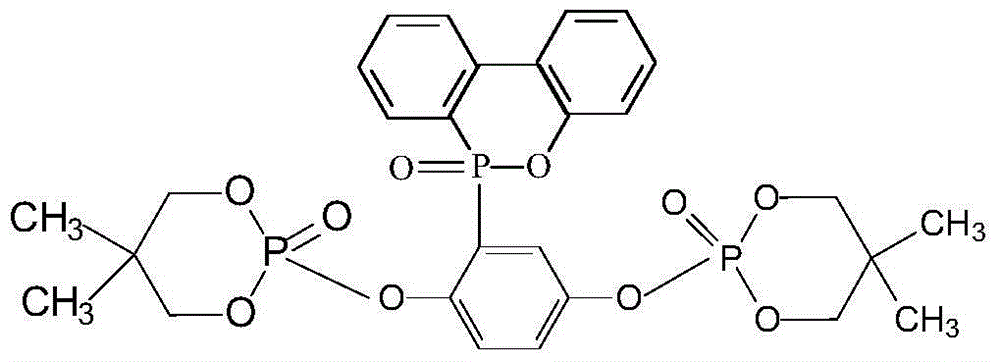

DOPO-containing dioxacaprophosphate flame retardant as well as preparation method and application thereof

A technology of caprolactone phosphate and flame retardant, which is applied in the field of phosphorus flame retardants, can solve the problems of not being able to meet the processing temperature of polymer materials, and achieve the effects of easy industrial production, high phosphorus content, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A preparation method of DOPO-containing dioxycaprolactophosphate flame retardant, the steps are:

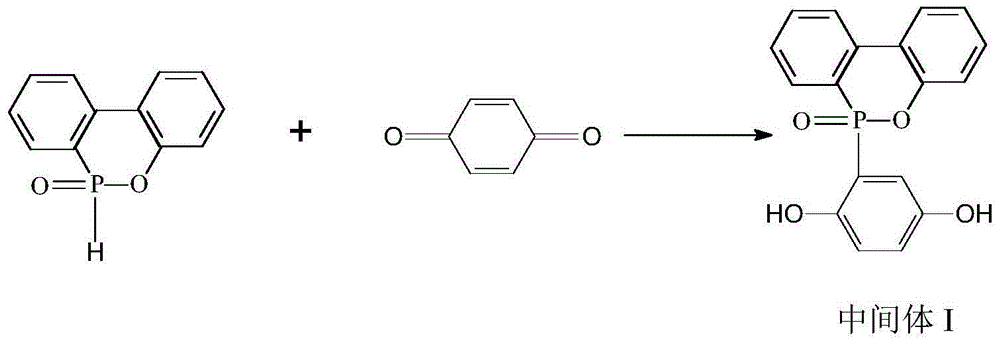

[0025] Under nitrogen protection, add 12g DOPO (0.055mol) and 300mL toluene to the three-necked flask, heat and stir until DOPO is completely dissolved in toluene, add 5g p-benzoquinone (0.046mol), and stir the reaction at 100°C for 5h. The resulting precipitate was cooled to room temperature, filtered, reconstituted with methanol, and dried to obtain Intermediate I as a white solid.

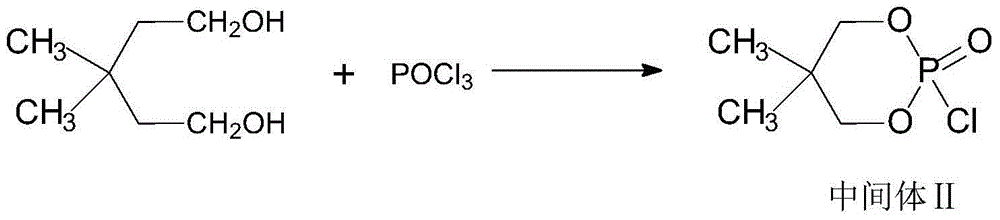

[0026] Add 52.0g (0.5mol) of neopentyl glycol and 200mL of chloroform into the flask, slowly add 84.3g (0.55mol) of phosphorus oxychloride dropwise under stirring, and react at 65°C for 6h after the dropwise addition. After the reaction was completed, chloroform and excess phosphorus oxychloride were distilled off to obtain a white solid, which was recrystallized and dried to obtain intermediate II with a yield of 91.2%.

[0027] In a round-bottomed flask with 100 mL of acetonitrile, add 3....

Embodiment 2

[0034] The solvent was changed to THF, and the others were the same as Example 1. The yield of the target compound was 85.1%, and the melting point was 233-235° C.

[0035] The solvent was replaced by DMF, and the others were the same as Example 1. The yield of the target compound was 83.2%, and the melting point was 233-235°C.

Embodiment 3

[0037] Increase the amount of intermediate II to 4.79 g (0.026 mol), and the others are the same as Example 1. The yield of the target compound is 90.5%, and the melting point is 233-235°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com