Chromium-free passivation solution for electro-galvanized steel plate and preparation method of passivation solution

A chromium-free passivation and electro-galvanizing technology, applied in the direction of metal material coating process, can solve the problem of not reaching the corrosion resistance of the passivation layer, achieve good corrosion resistance and oxidation resistance, and improve corrosion resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

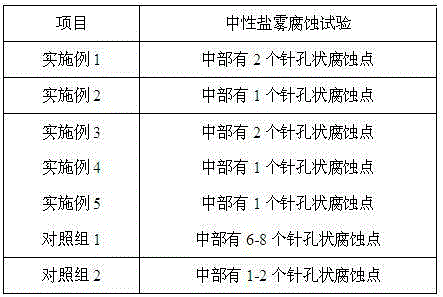

Examples

Embodiment 1

[0023] A chromium-free passivation solution for electrogalvanized steel sheets, prepared from the following components in parts by mass: 8 parts of zinc vanadate, 6 parts of sodium molybdate, 8 parts of phosphoric acid, 3 parts of sodium bisulfite, and 5 parts of phytic acid 2 parts, 2 parts of diphenolic propane, 2 parts of sodium metasilicate, 3 parts of ethylene glycol and 15 parts of deionized water.

[0024] According to the preparation method provided by the invention, the above-mentioned chromium-free passivation solution for electro-galvanized steel sheets is prepared, and the preparation steps are as follows:

[0025] (1) Add vanadate and molybdate into deionized water, heat in a water bath at a temperature of 60°C, stir while adding, and mix well to obtain a mixed solution of vanadate and molybdate;

[0026] (2) Add phosphoric acid and phytic acid to the above mixed solution and stir evenly;

[0027] (3) Ultrasonically disperse sodium bisulfite and diphenolic propan...

Embodiment 2

[0030] A chromium-free passivation solution for electrogalvanized steel sheets, prepared from the following components in parts by mass: 20 parts of lithium vanadate, 12 parts of potassium molybdate, 15 parts of phosphoric acid, 8 parts of sodium bisulfite, and 12 parts of phytic acid Parts, 6 parts of diphenolic propane, 5 parts of sodium metasilicate, 8 parts of ethylene glycol and 22 parts of deionized water.

[0031] According to the preparation method provided by the invention, the above-mentioned chromium-free passivation solution for electro-galvanized steel sheets is prepared, and the preparation steps are as follows:

[0032] (1) Add vanadate and molybdate into deionized water, heat in a water bath at a temperature of 60°C, stir while adding, and mix well to obtain a mixed solution of vanadate and molybdate;

[0033] (2) Add phosphoric acid and phytic acid to the above mixed solution and stir evenly;

[0034] (3) Ultrasonically disperse sodium bisulfite and diphenoli...

Embodiment 3

[0037] A chromium-free passivation solution for electrogalvanized steel sheets, prepared from the following components in parts by mass: 11 parts of sodium orthovanadate, 8 parts of sodium molybdate, 10 parts of phosphoric acid, 4 parts of sodium bisulfite, phytic acid 7 parts, 3 parts of diphenolic propane, 4 parts of sodium metasilicate, 5 parts of ethylene glycol and 15 parts of deionized water.

[0038] According to the preparation method provided by the invention, the above-mentioned chromium-free passivation solution for electro-galvanized steel sheets is prepared, and the preparation steps are as follows:

[0039] (1) Add vanadate and molybdate into deionized water, heat in a water bath at a temperature of 60°C, stir while adding, and mix well to obtain a mixed solution of vanadate and molybdate;

[0040] (2) Add phosphoric acid and phytic acid to the above mixed solution and stir evenly;

[0041] (3) Ultrasonically disperse sodium bisulfite and diphenolic propane into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com