Ceramic composite separator and preparation method thereof

A ceramic composite and diaphragm technology, applied in the field of electrochemistry, can solve the problems of affecting the long-term stability of the diaphragm, low lithium ion conductivity, and the ceramic layer is easy to fall off, so as to improve the ion conductivity, improve the stability and service life, high The effect of heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention also provides a preparation method for the above-mentioned ceramic composite diaphragm, comprising the following steps:

[0031] The polymer film is treated with plasma to obtain a polymer film with a certain concave-convex structure on the surface;

[0032] Dispersing the ceramic material and the binder in a solvent to obtain a ceramic coating liquid, the ceramic material including a fast ion conductor;

[0033] The ceramic coating solution is covered on the surface of the polymer film, and the solvent is removed to obtain a ceramic composite diaphragm.

[0034] In the present invention, the polymer film is treated with plasma, and the plasma treatment is carried out in an air atmosphere, the treatment intensity is 20-500W, preferably 20-40W, more preferably 25-35W, and the treatment temperature is 60-80°C After treatment for 10-120s under the condition of 15-40°C for 10-120s. After the above plasma treatment, a polymer film with a certain conca...

Embodiment 1

[0050] The commercially available polypropylene diaphragm of Celgard Company in the United States was treated with plasma, and the treatment was carried out in an air atmosphere with a treatment intensity of 20W. First, it was treated at 60°C for 10s, and then at 15°C for 10s to obtain a surface with a certain concave-convex structure. . The zinc germanate lithium type lithium fast ion conductor Li with a mass ratio of 1:0.05 4 Zn(GeO 4 ) 4 and polyvinylidene fluoride are dispersed in acetone to prepare a uniform ceramic coating liquid, wherein the solid content of the coating liquid is 15%. Cover the surface of the polymer film with a concave-convex structure with a ceramic coating solution, and obtain the ceramic composite diaphragm after removing the solvent. The thickness of the ceramic composite diaphragm is 25 μm, wherein the thickness of the ceramic layer is 5 μm, and the polymer layer is The thickness is 20 μm.

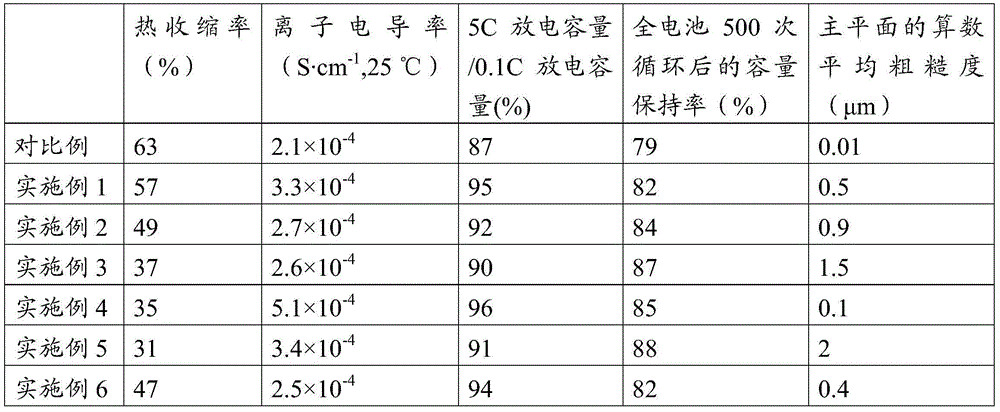

[0051] The ceramic composite diaphragms obtained abo...

Embodiment 2

[0057] The commercially available celgard polypropylene diaphragm was treated with plasma, and the treatment was carried out in an air atmosphere with a treatment intensity of 25W. It was first treated at 70°C for 70s, and then at 25°C for 70s to obtain a surface with a certain concave-convex structure. The NASICON type lithium fast ion conductor LiTi with a mass ratio of 1:0.25 2 (PO 4 ) 3 and polymethyl methacrylate are dispersed in dimethylformamide to prepare a uniform ceramic coating liquid, wherein the solid content of the coating liquid is 25%. Cover the surface of the polymer film with a concave-convex structure with a ceramic coating solution, and obtain the ceramic composite diaphragm after removing the solvent. The thickness of the ceramic composite diaphragm is 30 μm, wherein the thickness of the ceramic layer is 11 μm, and the polymer The thickness of the layer was 19 μm.

[0058] The ceramic composite diaphragms obtained above were measured according to the me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Arithmetic mean roughness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Diameter size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com