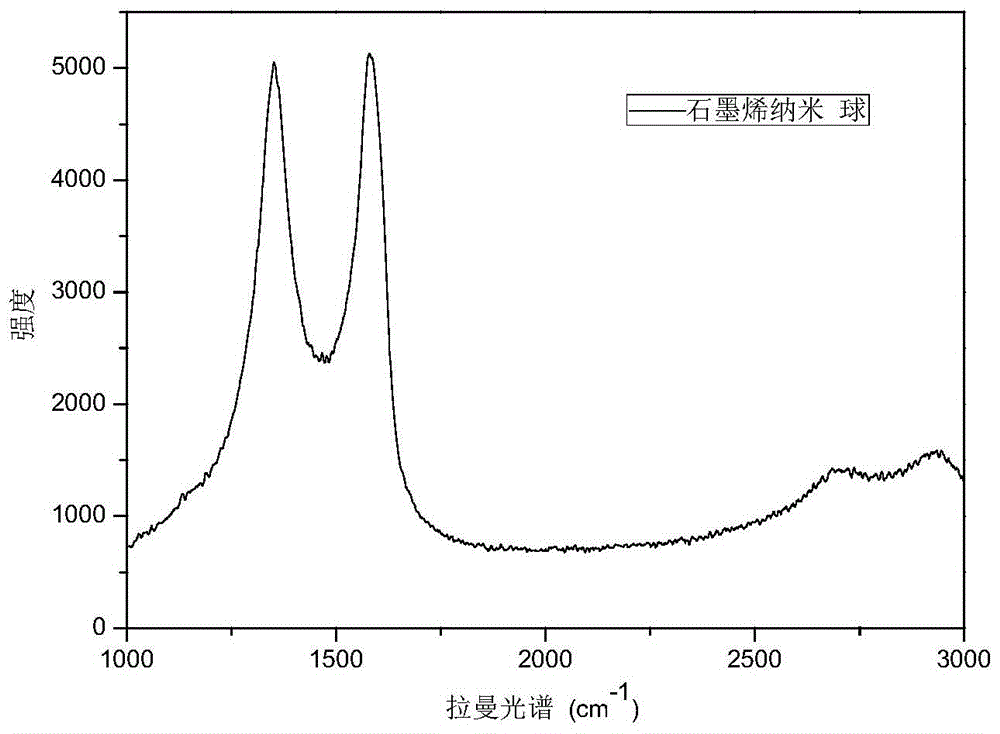

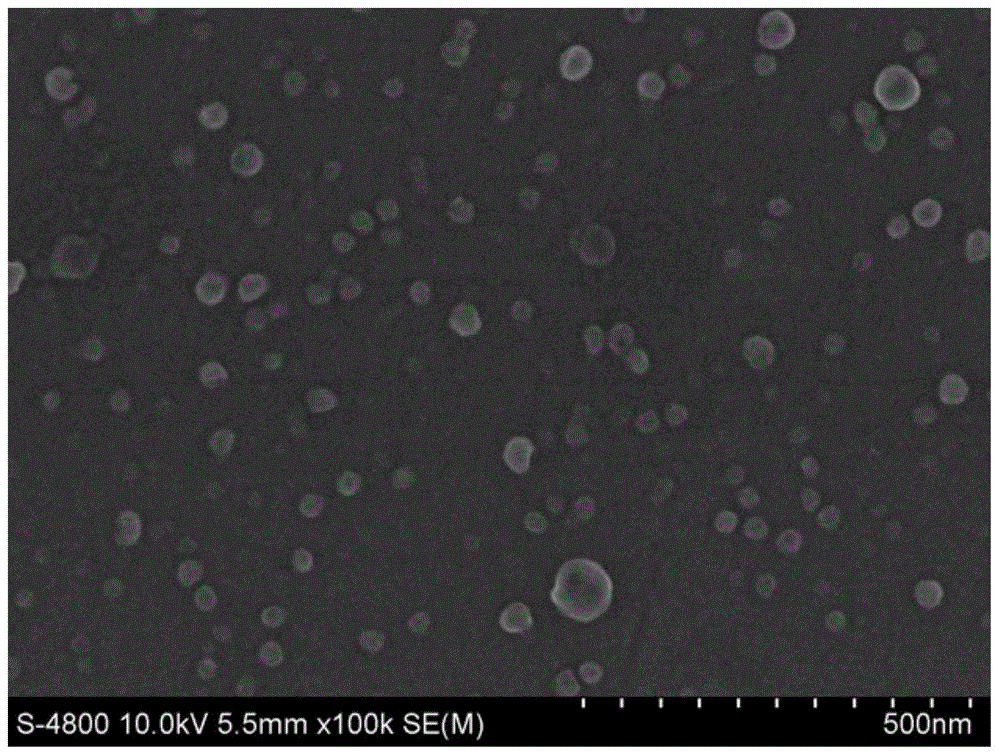

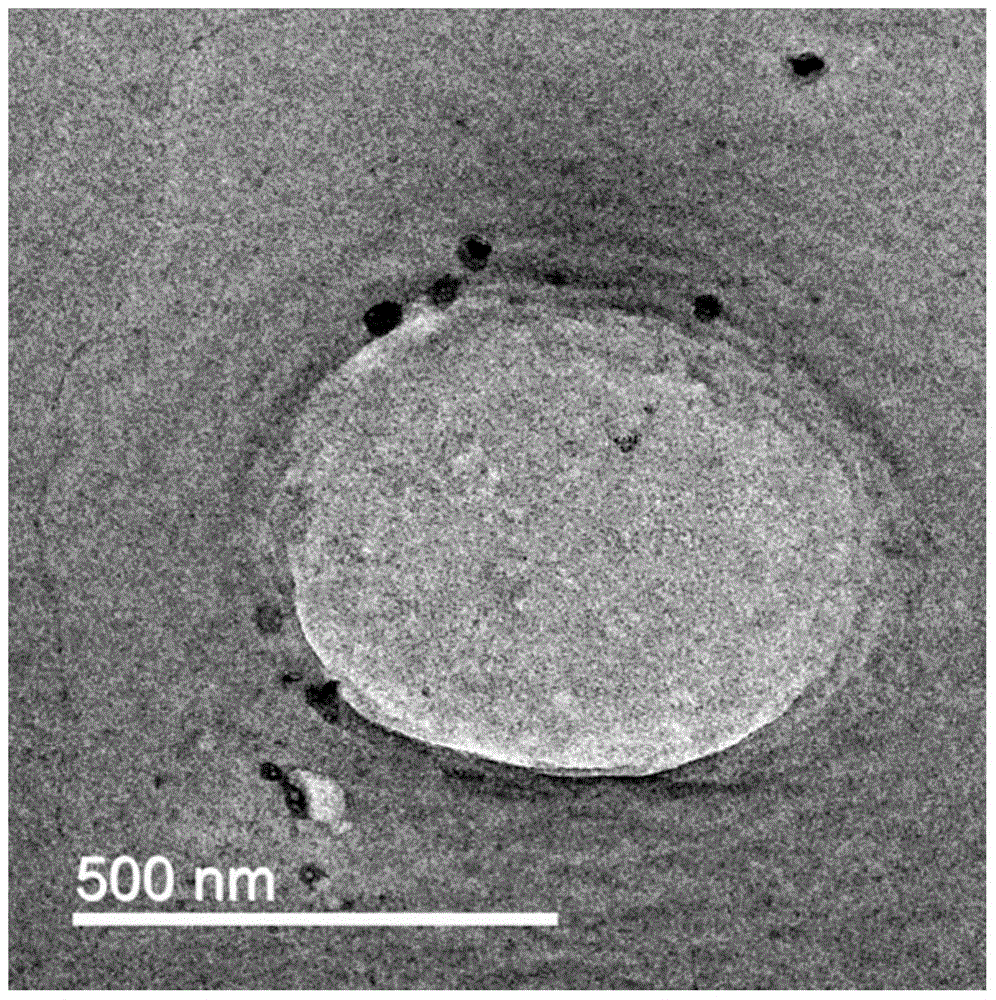

A kind of preparation method of graphene nanosphere

A technology of nanospheres and graphene, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of preparation limitations, and achieve the effect of low synthesis cost, simple synthesis circuit and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Preparation of graphene oxide miniemulsion

[0027] At room temperature, add 40mL cyclohexane to a 50mL beaker, add 2.030g Span 80 and n-butanol respectively (the mass fraction ratio of Span 80 and n-butanol in this system is 1:1), and then add 1mL graphene oxide solution (5 mg / mL). After magnetic stirring (300rpm) in an ice-water bath, through ultrasonic emulsification, the ultrasonic power is 200W, the ultrasonic time is 10min, and the ultrasonic mode is 200w power pulse ultrasonic. After working for 2s, work for 2s and then work for 2s. Repeat this to form a stable and uniform fine emulsion.

[0028] (2) Preparation of graphene oxide nanogel spheres

[0029] Transfer the above-mentioned miniemulsion to a 100mL three-necked flask and place it in a water bath at 60°C, and stir it magnetically (150rpm). Speed centrifugation for 30 min, remove the supernatant, and disperse the lower precipitate to obtain the alcohol dispersion of graphene oxide nanogel balls.

...

Embodiment 2

[0034] (1) Preparation of graphene oxide miniemulsion

[0035] At room temperature, add 40mL cyclohexane into a 50mL beaker, add 2.0g Triton X-100 and n-butanol respectively (the mass-number ratio of Triton X-100 and n-butanol in this system is 1:1), and then add 1mL Graphene oxide solution (11 mg / mL). Via magnetic stirring (300rpm) in an ice-water bath, ultrasonic emulsification is performed, the ultrasonic power is 200W, and the ultrasonic time is 10min. Forms a stable and homogeneous fine emulsion.

[0036] (2) Preparation of graphene oxide nanogel spheres

[0037] Transfer the above-mentioned miniemulsion to a 100mL three-necked flask and place it in a water bath at 70°C, and stir it magnetically (150rpm). Speed centrifugation for 30 min, remove the supernatant, and disperse the lower precipitate to obtain the alcohol dispersion of graphene oxide nanogel balls.

[0038] (3) Preparation of graphene nanospheres

[0039] Add 20 mL of graphene oxide nanospheres to 50 μL...

Embodiment 3

[0042] (1) Preparation of graphene oxide miniemulsion

[0043] At room temperature, add 40mL cyclohexane to a 50mL beaker, add 2.0g Span 80 and n-butanol respectively (the mass fraction ratio of Span 80 and n-butanol in this system is 1:1), and then add 1mL graphene oxide solution (15mg / mL). Via magnetic stirring (300rpm) in an ice-water bath, ultrasonic emulsification is performed, the ultrasonic power is 200W, and the ultrasonic time is 10min. Forms a stable and homogeneous fine emulsion.

[0044] (2) Preparation of graphene oxide nanogel spheres

[0045] Transfer the above-mentioned miniemulsion to a 100mL three-necked flask and place it in a water bath at 65°C, and stir it magnetically (150rpm). Speed centrifugation for 30 min, remove the supernatant, and disperse the lower precipitate to obtain the alcohol dispersion of graphene oxide nanogel balls.

[0046] (3) Preparation of graphene nanospheres

[0047] Add 0.1 mg of sodium borohydride to 20 mL of graphene oxide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com