Firing process of bone-china

A bone china and craft technology, which is applied in the field of bone china firing technology, can solve the problems of restricting the production and popularization of bone china, difficult to control the production process, unstable product quality, etc., and achieves stable product quality and good transparency. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) Synthetic bone meal

[0018] Add calcium hydroxide and phosphoric acid into the reaction tank according to the mass ratio of 1:1, react at 60°C for 15h, press filter with a filter press, so that the mass content of water in the filter cake is 8%, after drying, dry at 1180 Calcining at ℃ for 20 hours, magnetic separation to remove iron, and obtain synthetic bone meal;

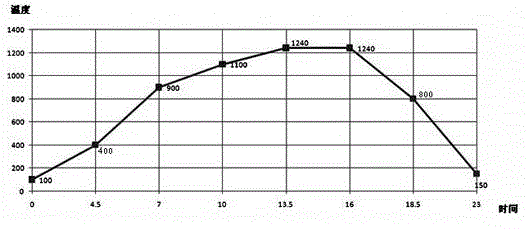

[0019] (2) Preparation of bone china

[0020] Use 40kg of synthetic bone powder, 40kg of crystal quartz powder, 20kg of kaolin and 10kg of potassium feldspar, and add 50kg of water to grind it for 20 hours with a ball mill to obtain a powder with a fineness of 250 meshes, and filter it with a filter press to obtain mud flakes, so that the mud flakes contain The water content is 18wt%. After the mud flakes are made into mud strips by a vacuum mud mill, the mud is shaped and dried by a mechanism to obtain an embryo body; Trim the billet and put it into a firing furnace with a temperature of 100°C for ...

Embodiment 2

[0023] (1) Synthetic bone meal

[0024] Add calcium hydroxide and phosphoric acid into the reaction tank according to the mass ratio of 1:1, react at 80°C for 10 hours, press filter with a filter press, so that the mass content of water in the filter cake is 6%, after drying, dry at 1180°C Calcining at lower temperature for 10 hours, removing iron by magnetic separation to obtain synthetic bone powder;

[0025] (2) Preparation of bone china

[0026] Use 50kg of synthetic bone meal, 30kg of crystal quartz powder, 35kg of kaolin and 5kg of potassium feldspar, and use a ball mill to add 100kg of water to grind for 25 hours to obtain a powder with a fineness of 250 meshes, and use a filter press to obtain a mud sheet. After the mud flakes are made into mud strips by a vacuum mud mill, the mud is shaped and dried to obtain an embryo body; the firing furnace is heated to 100°C, and the molded embryo body is processed Trim the billet and put it into a firing furnace with a temperat...

Embodiment 3

[0029] (1) Synthetic bone meal

[0030] Add calcium hydroxide and phosphoric acid into the reaction tank according to the mass ratio of 1:1, react at 70°C for 12 hours, press filter with a filter press, so that the mass content of water in the filter cake is 7%, after drying, dry at 1180°C Lower calcining for 15 hours, magnetic separation to remove iron, to obtain synthetic bone powder; the detection index of synthetic bone powder is as follows:

[0031] (2) Preparation of bone china

[0032] Use 45kg of synthetic bone powder, 35kg of crystal quartz powder, 30kg of kaolin and 8kg of potassium feldspar, and use a ball mill to add 75kg of water to grind for 22 hours to obtain a powder with a fineness of 250 meshes, and use a filter press to obtain a mud sheet. After the mud flakes are made into mud strips by a vacuum mud mill, the mud is shaped and dried by a mechanism to obtain an embryo body; the firing furnace is heated to 100°C, and the embryo body obtained by molding is pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Whiteness | aaaaa | aaaaa |

| Whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com