Color super absorbent resin for soilless culture and preparation method thereof

A technology of superabsorbent resin and soilless cultivation, which is applied in the field of superabsorbent materials, can solve problems such as decolorization, and achieve the effects of uniform color, good bonding fastness, and good market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of the above-mentioned colored superabsorbent resin specifically includes the following steps:

[0036] Step 1, adding acrylamide monomer purified by recrystallization into water and stirring evenly to obtain an aqueous acrylamide solution; wherein, the mass ratio of acrylamide monomer to water is 1:1-5;

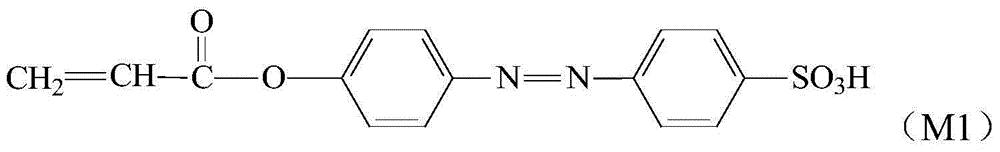

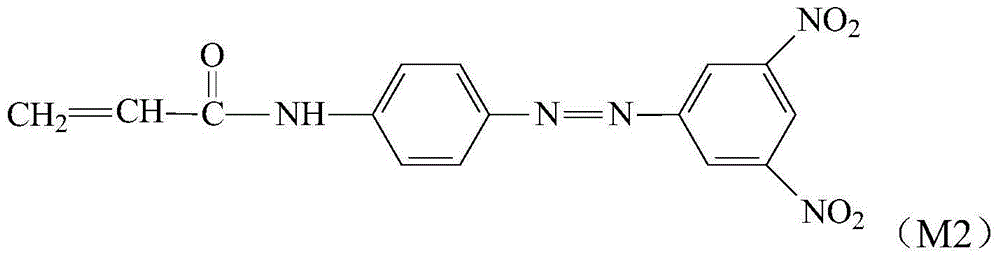

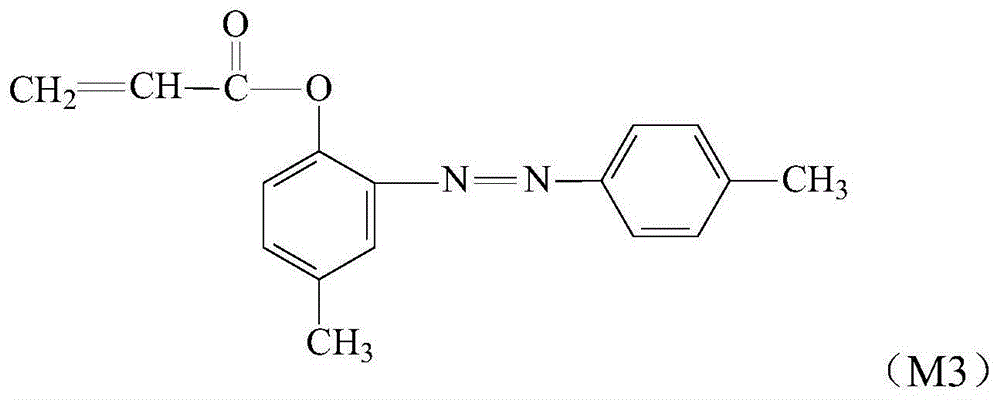

[0037]Step 2, adding dye monomers to the acrylamide aqueous solution obtained in step 1, placing them in an ultrasonic device, stirring evenly under ultrasonic radiation conditions to obtain a mixture A, and the ultrasonic power is 50-200W; wherein the acrylamide monomer and the dye monomer The mass ratio of monomer is 1:0.01~0.1; the dye monomer is a water-soluble azo dye with double bond, for example, the yellow one is: 4-acryloyloxy-4'-sulfonic acid Azobenzene, 1-(4-acryloyloxyphenylazo)-9,10-anthraquinone, etc.; green ones are: 4-acrylamido-4'-chloroazobenzene, 4 -Acrylamido-3',5'-dinitroazobenzene, 4-acrylamido-2',4'-dinitroazobenzene, etc...

Embodiment 1

[0043] Dissolve 10g of acrylamide in 10mL of distilled water, then add 0.1g of dye monomer M1, place in an ultrasonic device (such as an ultrasonic cleaner with a power of 50W), and stir evenly under ultrasonic conditions; Add 0.0001g of cross-linking agent N, N'-methylenebisacrylamide, and stir evenly; then add 0.01g of initiator potassium persulfate to the above mixture, fully stir and mix uniformly, under ultrasonic radiation conditions (ultrasonic power 50W), control the reaction temperature to be 80°C, and keep stirring for 30 minutes to obtain the crude product containing water; vacuum-dry the crude product containing water obtained, mechanically pulverize and pass through an 80-mesh sieve to obtain a dry crude product, and dry the crude product The product is placed in a 200-mesh nylon filter, soaked in distilled water for 12 hours to remove possible unreacted monomers, and the soaked product is collected, dried and pulverized to obtain a golden yellow superabsorbent res...

Embodiment 2

[0050] Dissolve 10g of acrylamide in 50mL of distilled water, then add 1g of dye monomer M2, place in an ultrasonic device (such as an ultrasonic cleaner with a power of 200W), and stir evenly under ultrasonic conditions; Add 0.01g of cross-linking agent N, N'-methylenebisacrylamide, and stir evenly; then add 0.1g of initiator ammonium persulfate to the above mixture, stir and mix well, and then under ultrasonic radiation conditions (ultrasonic power is 200W), control the reaction temperature to be 65°C, keep the stirring reaction for 60 minutes, and obtain the crude product containing water; vacuum-dry the crude product containing water obtained, pass through an 80-mesh sieve after mechanical crushing to obtain the dry crude product, and dry the crude product Place in a 200-mesh nylon filter, soak in distilled water for 24 hours to remove possible unreacted monomers, collect, dry and pulverize the soaked product to obtain a green superabsorbent resin.

[0051] Said dye monome...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com