Biodegradable and absorbable magnesium-zinc-copper alloy with antibiotic function, and application thereof

A technology of copper alloy and magnesium alloy, which is applied in the fields of coating, medical science, surgery, etc., can solve the problems of increasing the fracture and delamination of coatings and implants, the inability to achieve infection prevention and treatment, and the inability to solve the problem of antibiotic resistance, etc. Achieve satisfactory degradability, prevention and treatment of surrounding infection, and good application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

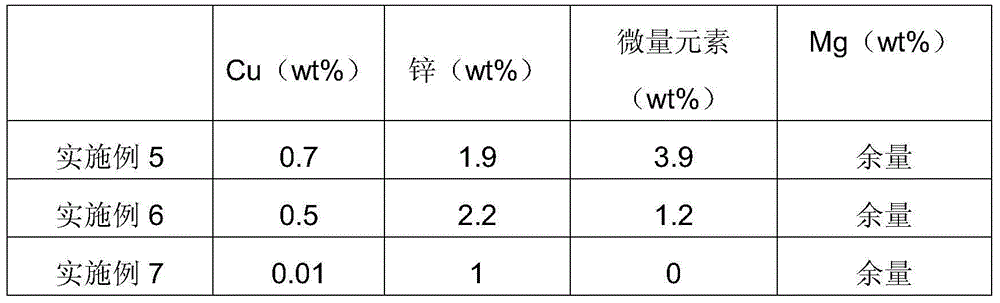

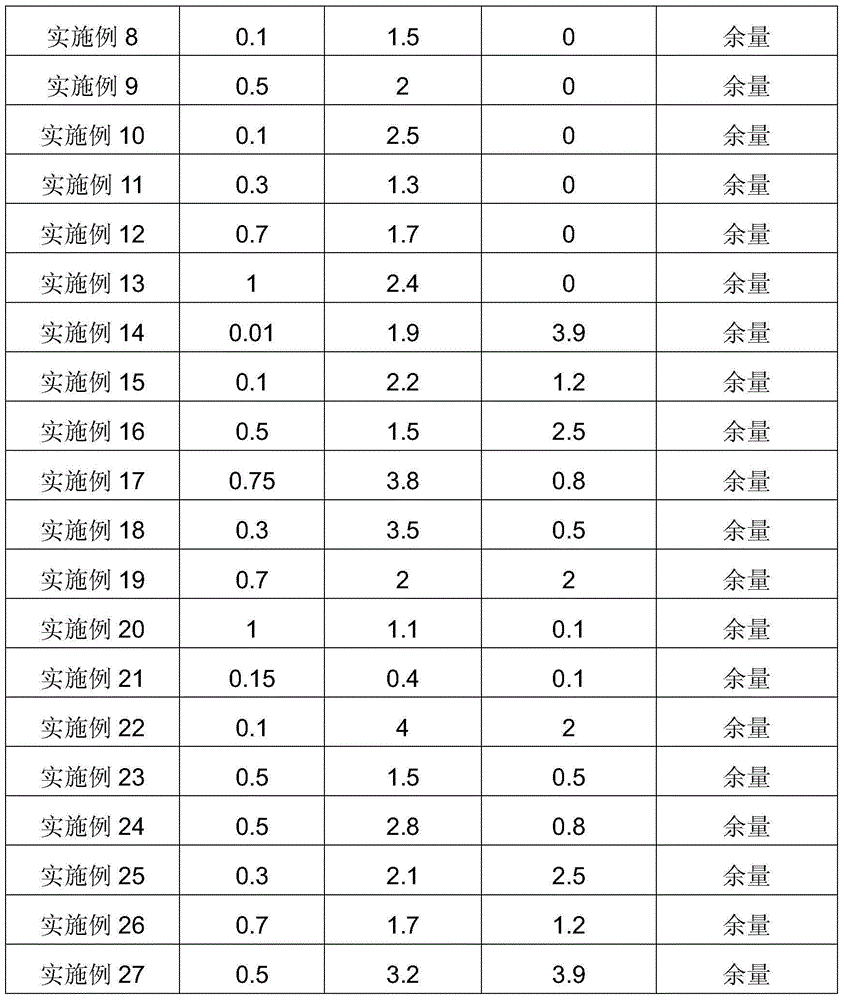

[0039] This embodiment provides a degradable and absorbable magnesium-zinc-copper alloy for medical use. The components of the magnesium-zinc-copper alloy include magnesium, copper and zinc. In terms of weight percentage, the magnesium-zinc-copper alloy contains copper ≤ 3wt% (such as 0.25wt%, 0.5wt%, 1wt%, 2wt%, 3wt%), zinc (Zn) ≤ 6wt% (such as 0.5wt%, 1wt%) %, 2.5wt%, 4wt%, 5wt% or 6wt%), the balance is magnesium.

Embodiment 2

[0041]This embodiment provides a medical degradable and absorbable magnesium-zinc-copper alloy. The components of the magnesium-zinc-copper alloy include magnesium, zinc, copper, and trace elements, and the trace elements are neodymium. Magnesium-zinc-copper alloy contains copper ≤ 3wt% (such as 0.25wt%, 0.5wt%, 1wt%, 2wt%, 3wt%), zinc (Zn) ≤ 4wt% (such as 0.25wt%, 0.5wt%, 1wt%, 2wt%) % or 4wt%), neodymium (Nd) ≤ 2wt% (such as 0.15wt%, 0.5wt%, 1wt%, or 2wt%), and the balance is magnesium.

Embodiment 3

[0043] This embodiment provides a medical degradable and absorbable magnesium-zinc-copper alloy. The magnesium-zinc-copper alloy contains 0.1wt% copper, 1.5wt% zinc and the balance magnesium, using high-purity raw materials and high-cleanliness smelting technology to manufacture.

[0044] After testing, the magnesium-zinc-copper alloy provided in this embodiment has a tensile strength of 190 MPa and an elongation of 20%.

[0045] The biological evaluation of the magnesium-zinc-copper alloy provided in this example was carried out according to the experimental method described in GB / T16886. Experimental results show that the magnesium-zinc-copper alloy provided in this example has no obvious cytotoxicity and blood coagulation on osteoblasts and bone marrow mesenchymal stem cells, and has no obvious sensitization, stimulation and genotoxicity.

[0046] The magnesium-zinc-copper alloy provided in this embodiment is further processed into a magnesium-zinc-copper alloy intramedull...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com