Catalyst support for purification of exhaust gas, catalyst for purification of exhaust gas using same, and method for producing catalyst support for purification of exhaust gas

一种催化剂载体、净化废气的技术,应用在催化剂活化/制备、物理/化学过程催化剂、非均相催化剂化学元素等方向,能够解决耐热性不如贵金属、晶粒生长、OSC或催化活性降低等问题,达到抑制晶粒生长、大总孔隙体积和比表面积的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0123] First, 13.75 g of cerium ammonium nitrate, 12.43 g of zirconyl nitrate, 0.82 g of yttrium nitrate, 8.78 g of aluminum nitrate, and 1.24 g of lanthanum nitrate were dissolved in 500 g of ion-exchanged water to prepare a first raw material solution containing cations , these cations will be used as raw materials for porous composite metal oxides. These additions correspond to a cation concentration of 0.1 mol / L, where A1 2 o 3 : CeO 2 : ZrO 2 : Y 2 o 3 : La 2 o 3 =10.0:36.2:47.9:2.0:3.9 (mass ratio). Next, 62.5 g of polyethyleneimine having a weight average molecular weight of 10000 represented by the following structural formula (1) and 78 g of nitric acid were dissolved in 360 g of ion-exchanged water to prepare a second raw material solution.

[0124] [Chemical Structural Formula 1]

[0125]

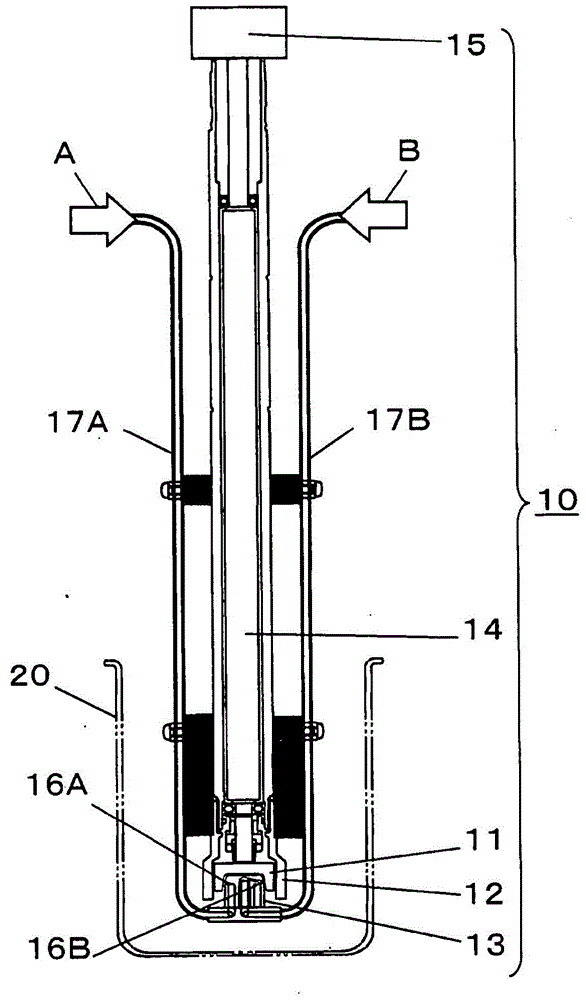

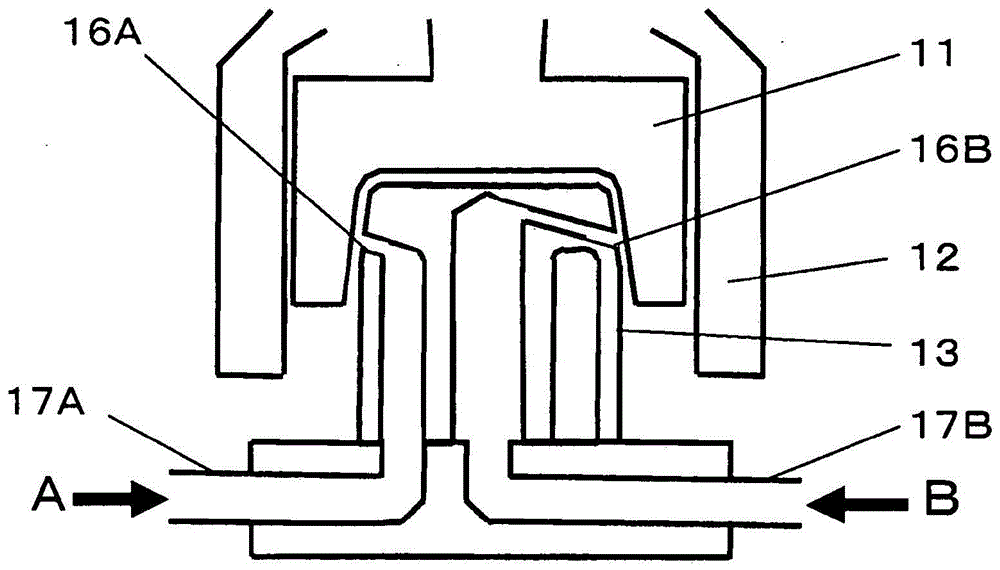

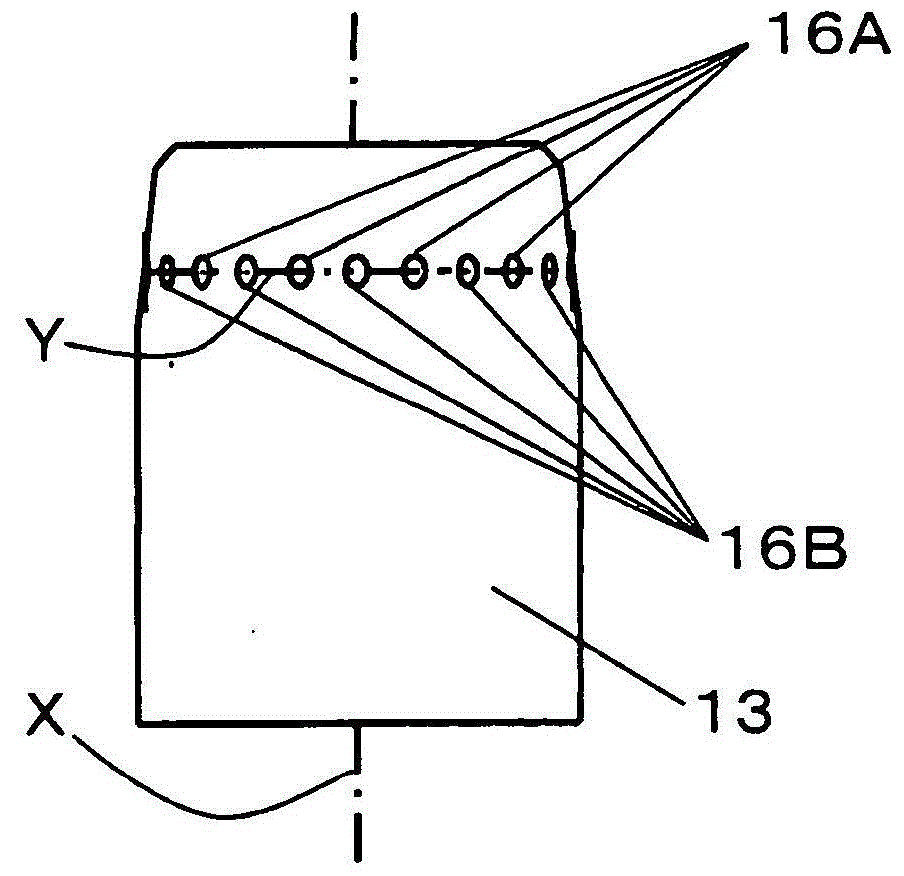

[0126] Next, by using figure 1 The production equipment shown in (SUPER AGITATION REACTOR) was used to prepare nano-colloidal solutions of metal compounds. It shoul...

example 2

[0130] 10.58 g of ceric ammonium nitrate, 9.51 g of zirconyl nitrate, 0.71 g of yttrium nitrate, 1.07 g of lanthanum nitrate, and 15.27 g of aluminum nitrate were dissolved in 500 g of ion-exchanged water to prepare an aqueous solution containing cations to be used as Raw materials for porous composite metal oxides. These additions correspond to a cation concentration of 0.1 mol / L, where A1 2 o 3 : CeO 2 : ZrO 2 : Y 2 o 3 : La 2 o 3 =20.0:31.9:42.2:2.0:3.9 (mass ratio). Except that this aqueous solution was used as the first raw material solution, similarly to Example 1, a transparent nanocolloid solution (pH 4) of a metal compound was prepared, and then, a porous composite metal oxide powder was prepared.

example 3

[0132] 8.22 g of ceric ammonium nitrate, 7.38 g of zirconium oxynitrate, 0.65 g of yttrium nitrate, 1.00 g of lanthanum nitrate, and 20.03 g of aluminum nitrate were dissolved in 500 g of ion-exchanged water to prepare an aqueous solution containing cations to be used as Raw materials for porous composite metal oxides. These additions correspond to a cation concentration of 0.1 mol / L, where A1 2 o 3 : CeO 2 : ZrO 2 : Y 2 o 3 : La 2 o 3 =29.5:27.9:36.9:2.0:3.9 (mass ratio). Except that this aqueous solution was used as the first raw material solution, similarly to Example 1, a transparent nanocolloid solution (pH 4) of a metal compound was prepared, and then, a porous composite metal oxide powder was prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com