Compound desalination membrane as well as preparation method and application thereof

A desalination membrane and microporous filtration membrane technology, applied in the field of composite desalination membrane and its preparation, can solve the problems of staying, not involving the industrial application of reduced graphene oxide and titanium oxide composite thin film, etc., to prevent transmembrane permeation, excellent Water desalination performance, area and thickness controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

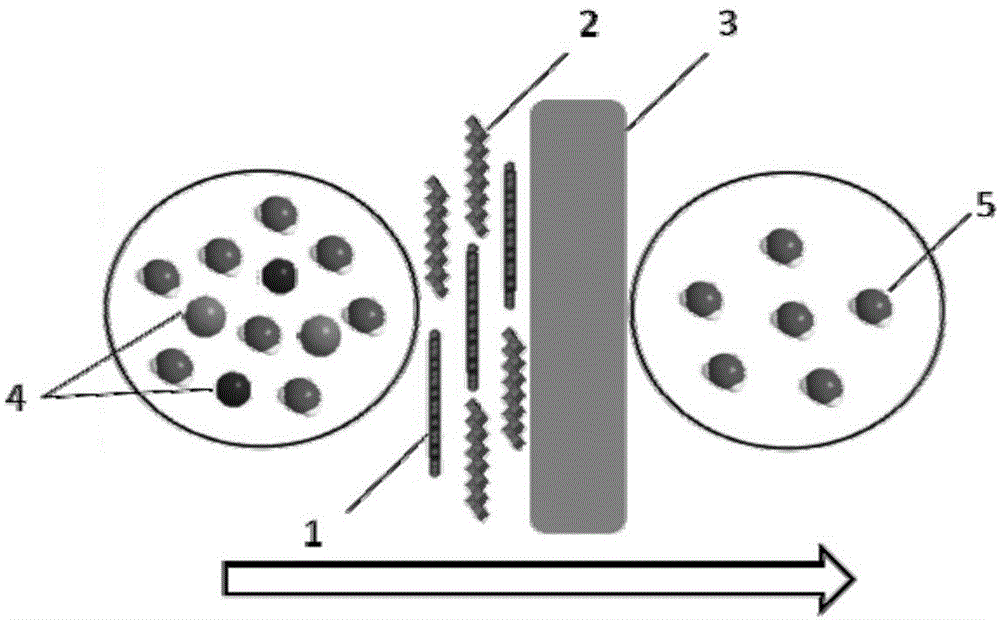

[0023] A method for preparing a composite desalination membrane provided by the present invention specifically comprises the following steps:

[0024] 1) Uniformly mix the aqueous solution containing graphene oxide flakes with the aqueous solution of titanium oxide nanosheets; the volume mass concentration of the graphene oxide aqueous solution is 0.5-40 mg / L, the volume mass concentration of the titanium oxide nano-sheet aqueous solution is 0.4-32 mg / L, and the oxidation In the mixed solution of graphene and titanium oxide nanosheets, the mass ratio of graphene oxide to titanium oxide nanosheets is 1:0.25-4;

[0025] 2) With the microporous membrane as the substrate, vacuum filtration is used to dehydrate the mixed solution of graphene oxide and titanium oxide nanosheets under negative pressure, and then stack and self-assemble into a layered film on the microporous membrane substrate 3 , dry at 40-80°C for 4-24 hours;

[0026] 3) By irradiating ultraviolet light for 1 to 5 ...

Embodiment 1

[0032] This embodiment includes the following steps:

[0033] 1) uniformly mix the aqueous solution comprising graphene oxide flakes with the aqueous solution of titanium oxide nanosheets; the volume mass concentration of graphene oxide aqueous solution is 40mg / L, the volume mass concentration of titanium oxide nanosheet aqueous solution is 32mg / L, graphene oxide and oxide In the mixed solution of titanium nanosheets, the mass ratio of graphene oxide to titanium oxide nanosheets is 1:0.8;

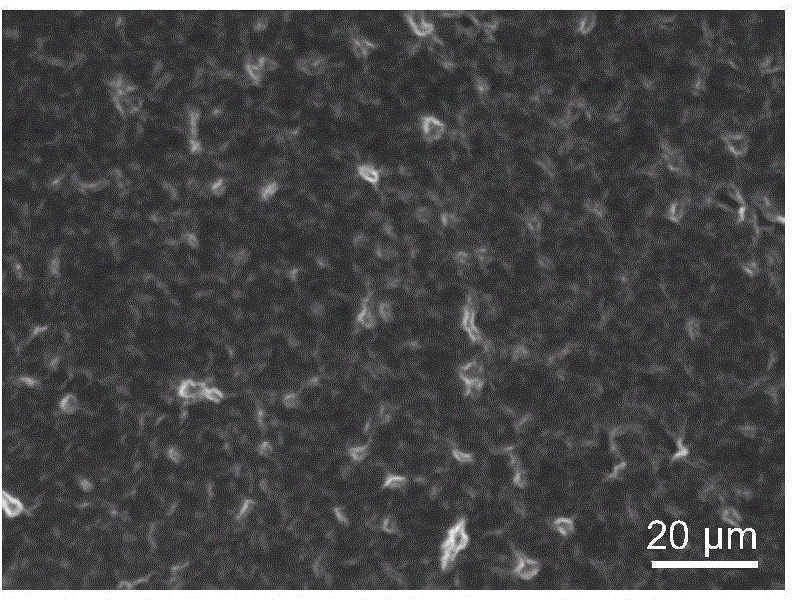

[0034] 2) Using a mixed cellulose microporous membrane with a pore size of 220nm as the substrate, the mixed solution of graphene oxide and titanium oxide nanosheets is dehydrated under negative pressure by vacuum filtration, and then stacked on the microporous membrane substrate Self-assembled into a layered film, dried at 55°C for 24 hours;

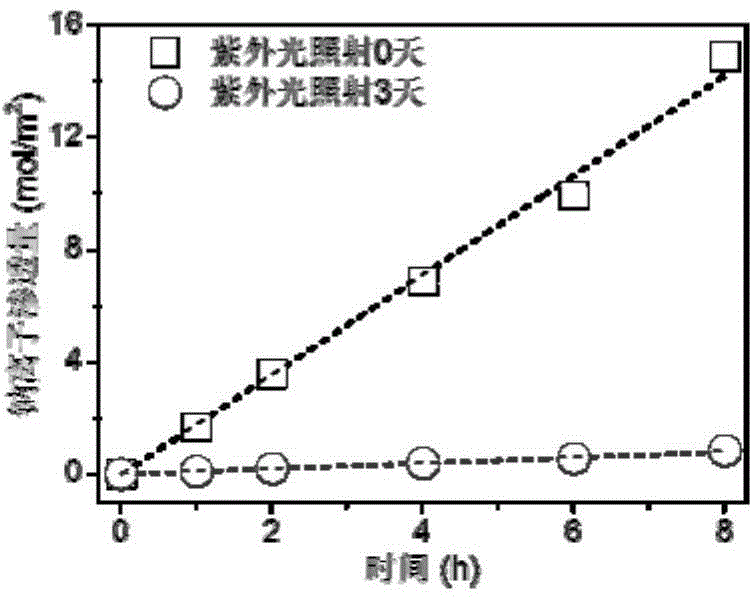

[0035] 3) After 3 days of ultraviolet light irradiation, the photocatalytic properties of titanium oxide nanosheets are used to uniformly transform...

Embodiment 2

[0039] This embodiment includes the following steps:

[0040] 1) uniformly mix the aqueous solution comprising graphene oxide flakes with the aqueous solution of titanium oxide nanosheets; the volume mass concentration of graphene oxide aqueous solution is 40 mg / L, the volume mass concentration of titanium oxide nanosheet aqueous solution is 10 mg / L, graphene oxide and oxide In the mixed solution of titanium nanosheets, the mass ratio of graphene oxide to titanium oxide nanosheets is 1:0.25;

[0041] 2) Based on the anodized alumina microporous filter membrane with a pore size of 100nm, the mixed solution of graphene oxide and titanium oxide nanosheets is dehydrated under negative pressure by vacuum filtration, and then stacked on the microporous membrane substrate Self-assembled into a layered film, dried at 40°C for 24 hours;

[0042] 3) By irradiating with ultraviolet light for 1 day, the photocatalytic properties of titanium oxide nanosheets are used to uniformly transfor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com