Preparation method of large-area super-hydrophobic flexible membrane

A flexible film and large-area technology, applied in the field of surface chemistry, can solve problems such as difficult to apply, not easy to bend, strong hydrophobic substrate, etc., and achieve the best mechanical strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

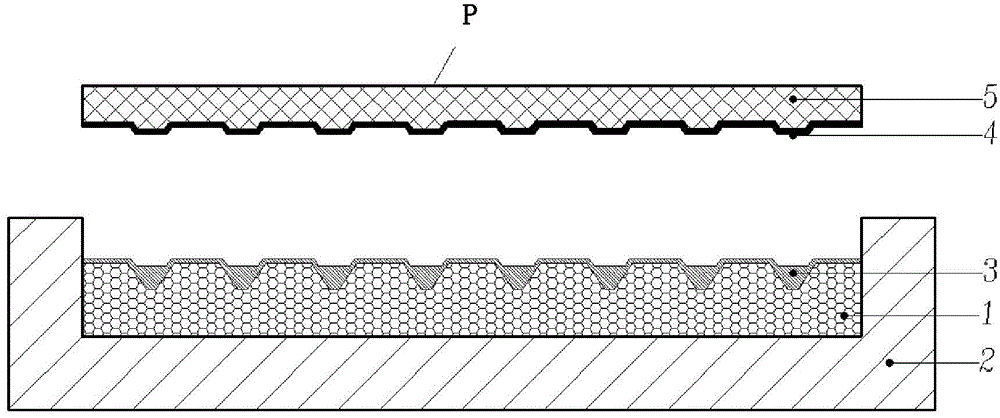

[0025] see figure 1 with 2 , the preparation method of the strong hydrophobic flexible film described in the present embodiment, comprises the following steps:

[0026] (1) Using micromachining technology (oxidation, photolithography, anisotropic wet etching, etc.) to manufacture parallel V-shaped microchannel arrays on silicon wafers; the opening width of the V-shaped channel is 5 μm, the depth is 15 μm, and the length The effective area of the overall channel on the silicon wafer 1 is 3000mm 2 .

[0027] (2) Assembling the silicon chip 1 with the microchannel array into the mold base plate 2;

[0028] (3) Spray release agent 3 and PVDF emulsion 4 on the upper surface of silicon wafer 1, then pour PDMS glue 5 (the ratio of PDMS matrix and curing agent is 10:2), then vacuumize and pre-cure, pre-cure The temperature is 60°C and the time is 15 minutes.

[0029] (4) Carry out chemical grafting treatment in an oxygen environment at a temperature of 135°C;

[0030] (5) Afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com