Production process of industrial high-quality naphthalene

A production method and high-quality technology, applied in the chemical industry, chemical instruments and methods, purification/separation of hydrocarbons, etc., can solve problems such as high labor intensity, intermittent operation, and large loss, and achieve low labor intensity, easy operation, and production small cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

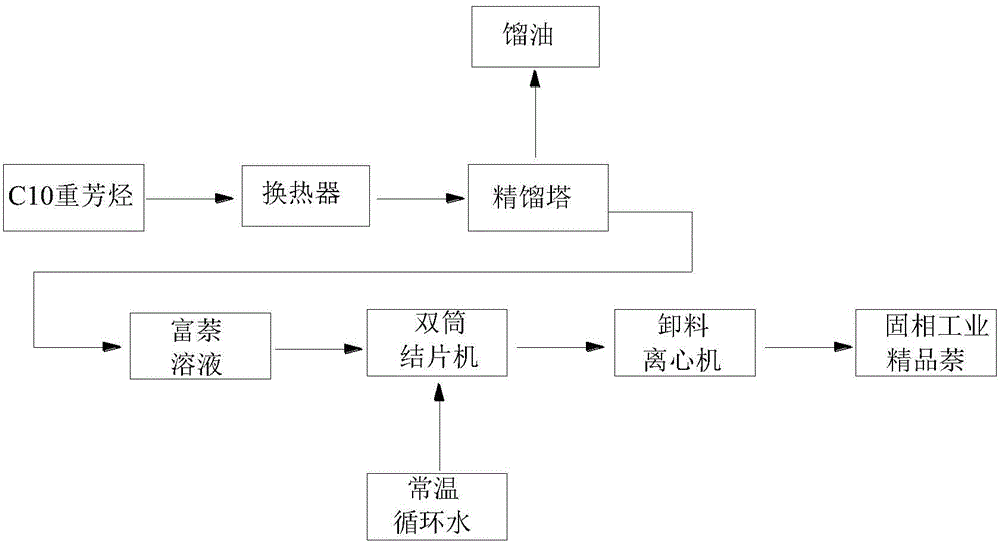

[0016] Below in conjunction with accompanying drawing, the present invention is further described:

[0017] A kind of production method of industrial high-quality naphthalene of the present invention, comprises the steps:

[0018] 1)C 10 The raw material of heavy aromatics is pumped into the heat exchanger for preheating, and then enters multiple rectification towers for rectification. The distillate oil enters the reflux tank, and the naphthalene-rich solution with a content of more than 40% and a temperature of 210-220°C is extracted from the side line of the rectification tower;

[0019] 2) The high-temperature naphthalene-rich solution after rectification enters from the feeding trough of the double-barrel flaker, and the normal-temperature circulating water whose temperature is controlled at 0-35°C is passed through the double-barrel flaker. The temperature difference of the circulating water is large, and cold and heat exchange occurs, which speeds up the heat transfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com