Extraction method of teasel root total saponins

An extraction method and technology of total saponins are applied in the field of extraction of discontinuous total saponins, which can solve the problems of polluted environment, cumbersome process and high production cost, and achieve the effects of reducing production energy consumption, simple extraction process and reduced use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

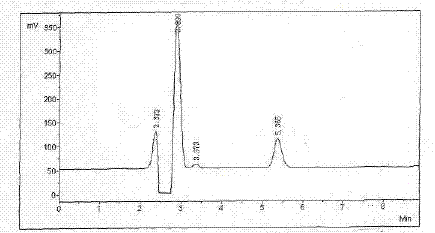

Image

Examples

Embodiment 1

[0021] Take the Dipsacus medicinal material, dry it, and crush it into a coarse powder of 10-80 mesh. Take 80kg of Dipsacus powder, add 200L, 150L, and 150L of 90% ethanol, respectively, and reflux and extract three times at 80°C for 2, 2, and 0.5 hours respectively. Combine the extracts, concentrate and recover the ethanol until it has no alcohol smell , add 20L water and heat at 80°C to dissolve, filter to obtain the filtrate; add 40L petroleum ether (boiling range 60-90°C) to the filtrate and stir evenly, keep stirring at 35°C for 30 minutes for deesterification, let stand for 4 hours, release the lower aqueous solution after layering , crystallization, filtering to obtain the crude product of Dipsacus total saponins, adding 32 kg of ethanol with 20% concentration to the crude product, heating and dissolving, recovering ethanol, drying, and obtaining 8.0 kg of total saponins.

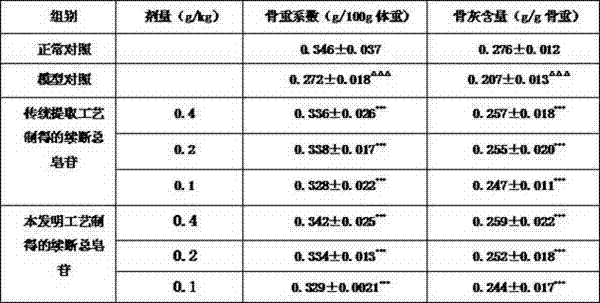

[0022] In the obtained extract, the weight percent content of total saponins of Dipsacus is 84....

Embodiment 2

[0024] Take the Dipsacus medicinal material, dry it, and crush it into a coarse powder of 30-60 mesh. Take 80kg of Dipsacus powder, add 200L, 150L, and 150L of absolute ethanol, reflux and extract three times at 78°C for 3, 2, and 1 hours respectively, combine the extracts, concentrate and recover the ethanol until there is no alcohol smell, add 40L Heat water at 70°C to dissolve, filter to obtain the filtrate; add 80L of petroleum ether (boiling range 60-90°C) to the filtrate and stir evenly, keep stirring at 45°C for 45 minutes to deesterify, let stand for 8 hours, release the lower aqueous solution after layering, and crystallize , filtered to obtain the crude product of Dipsacus total saponins, the crude product was added with 32 kg of ethanol with a concentration of 35% and heated for dissolving to recover ethanol, and dried to obtain 8.0 kg of total saponins.

[0025] In the obtained extract, the weight percent content of Dipsacus saponins is 92.9%, and Dipsacus saponi...

Embodiment 3

[0027] Take the Dipsacus medicinal material, dry it, and crush it into a coarse powder of 30-80 mesh. Dipsacus coarse powder 80kg, add 91% concentration of ethanol 300L, 200L, 150L, reflux extraction at 80 ℃ for three times, the extraction time is 3, 2, 2 hours respectively, combine the extracts, concentrate and recover ethanol until there is no alcohol smell, add Heat 80L of water at 55°C to dissolve, filter to obtain the filtrate; add 160L of petroleum ether (boiling range 60-90°C) to the filtrate and stir evenly, keep stirring at 55°C for 45 minutes for deesterification, let stand for 10 hours, release the lower layer of aqueous solution after separation, and analyze crystal, filtered to obtain the crude product of Dipsacus total saponins, the crude product was added with 30 kg of ethanol with 50% concentration, heated and dissolved, and then the ethanol was recovered, dried to obtain 11.2 kg of total saponins.

[0028] In the obtained extract, the weight percent content ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com