Acrylamide copolymer and preparation method and application thereof

A technology of acrylamide series and copolymers, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of polyacrylamide jelly temperature resistance and shear stability, and limitations, and achieve easy-to-obtain raw materials , The preparation method is simple, the effect of good high temperature shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

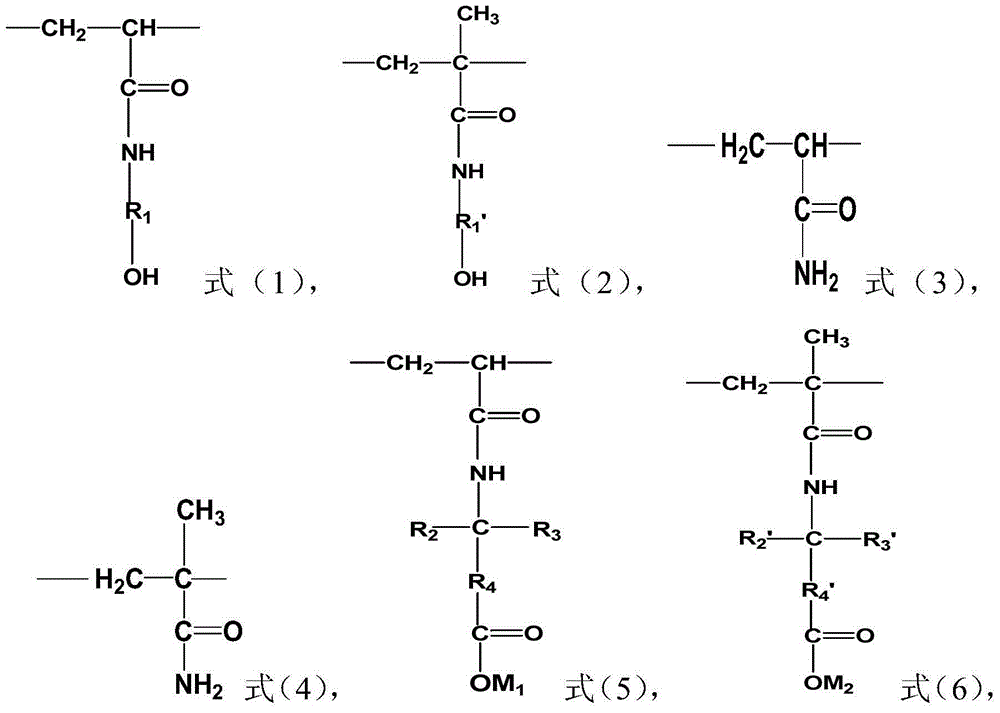

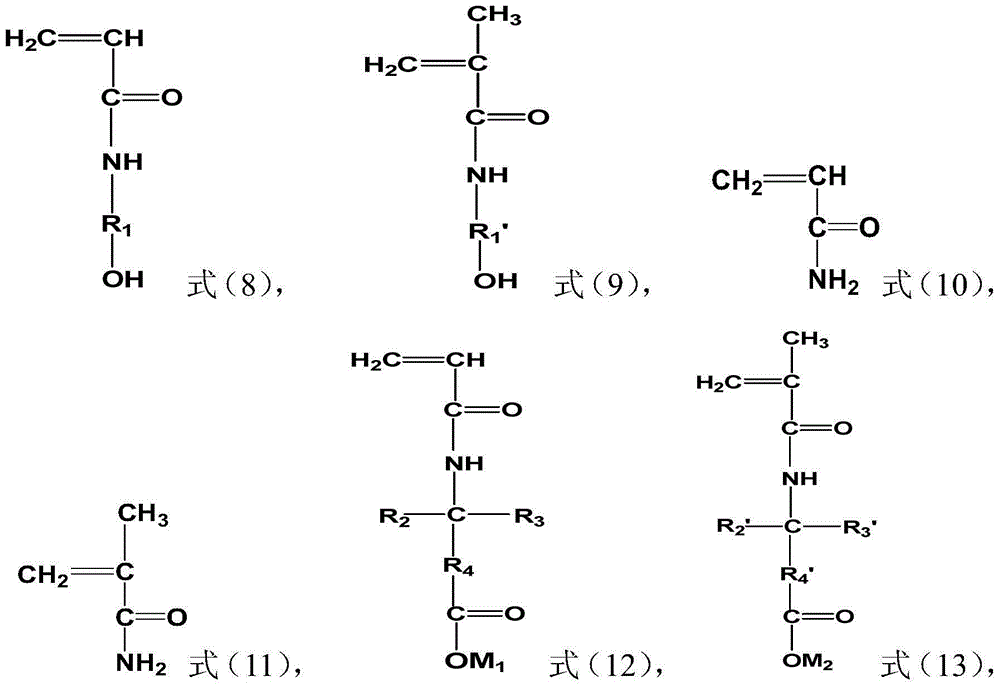

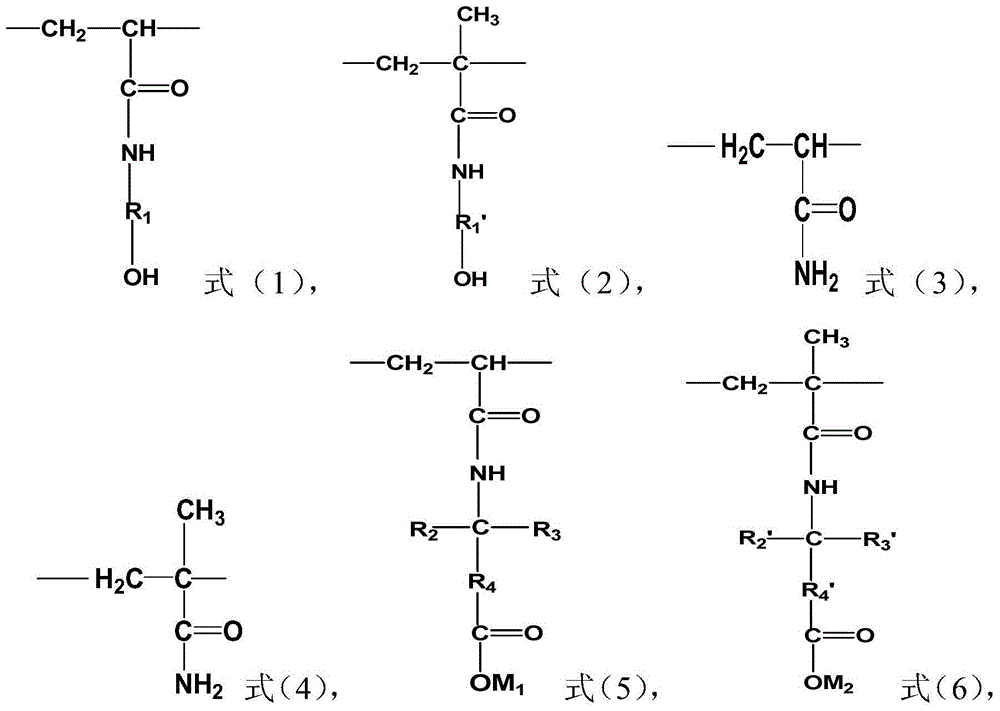

[0028] The present invention also provides a method for preparing an acrylamide-based copolymer, the preparation method comprising: under the condition of solution polymerization of olefins and in the presence of an initiator, a monomer mixture is polymerized in water, wherein the The monomer mixture contains monomer D, monomer E and monomer F, the monomer D is a monomer with the structure shown in formula (8) and / or formula (9), and the monomer E is a monomer with the formula ( 10) and / or a monomer with a structure shown in formula (11), the monomer F is a monomer with a structure shown in formula (12) and / or formula (13); and the monomer F in the monomer mixture The total number of moles of the monomer is based on the content of the monomer D is 5-25 mole %, the content of the monomer E is 60-90 mole %, and the content of the monomer F is 0.01-30 mole %; Preferably, the content of the monomer D is 10-20 mol%, the content of the monomer E is 70-85 mol%, and the content of the...

Embodiment 1

[0052] This example is used to illustrate the acrylamide copolymer and its preparation method.

[0053] Under cooling conditions at 0°C, 23.76 g of acrylamide (AM), 4.83 g of N-methylolacrylamide (N-MAM) and 16.35 g of 3-acrylamide-3- Methyl butyric acid (AMBA), add 180g of water, stir to dissolve the monomer completely, and obtain the aqueous solution of the monomer mixture. The pH was adjusted to 5.5 with sodium hydroxide solution. Pass N 2 After bubbling for 30 minutes, add 0.012g of 2,2'-azobis(2-amidinopropane) dihydrochloride (V50), 0.004g of ammonium persulfate (APS), 0.0025g of sodium bisulfite, The reaction mixture was prepolymerized at 20° C. for 1 hour, and then the reaction mixture was heated to 60° C. for 2 hours. The colorless transparent viscoelastic colloid P1 of the acrylamide-based copolymer was obtained by discharging the material. The properties of P1 were measured after granulation, drying, crushing and sieving. The measurement results are shown in Tabl...

Embodiment 2

[0061] This example is used to illustrate the acrylamide copolymer and its preparation method.

[0062] Under the condition of cooling at 0°C, 33.68g of acrylamide, 5.64g of N-methylolacrylamide and 4.77g of 3-acrylamide-3-methylbutanoic acid were successively added to a 250mL reactor, and 96.7g water, stirring to completely dissolve the monomers to obtain an aqueous solution of the monomer mixture. Adjust the pH to 8.5 with sodium hydroxide solution. Pass N 2 After bubbling for 30 minutes, 0.01 g of 2,2'-azobis(2-amidinopropane) dihydrochloride, 0.006 g of ammonium persulfate (APS) and 0.0028 g of sodium bisulfite were sequentially added to make the reaction mixture The reaction was carried out at 8° C. for 3 hours, and then the reaction mixture was heated to 70° C. for 1 hour. The colorless transparent viscoelastic colloid P2 of the acrylamide-based copolymer was obtained by discharging the material. After the P2 was granulated, dried, pulverized and sieved, various prope...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com