Rubber-plastic mixed composition, dynamically vulcanized thermoplastic elastomer and preparation method thereof

A thermoplastic elastomer, dynamic vulcanization technology, applied in the field of thermoplastic elastomer and its preparation, rubber-plastic blending composition, can solve the problems of poor compression set, poor dispersion of rubber phase, poor high temperature resistance, etc., and achieve excellent electrical properties , good thermal stability, and uniform vulcanization state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

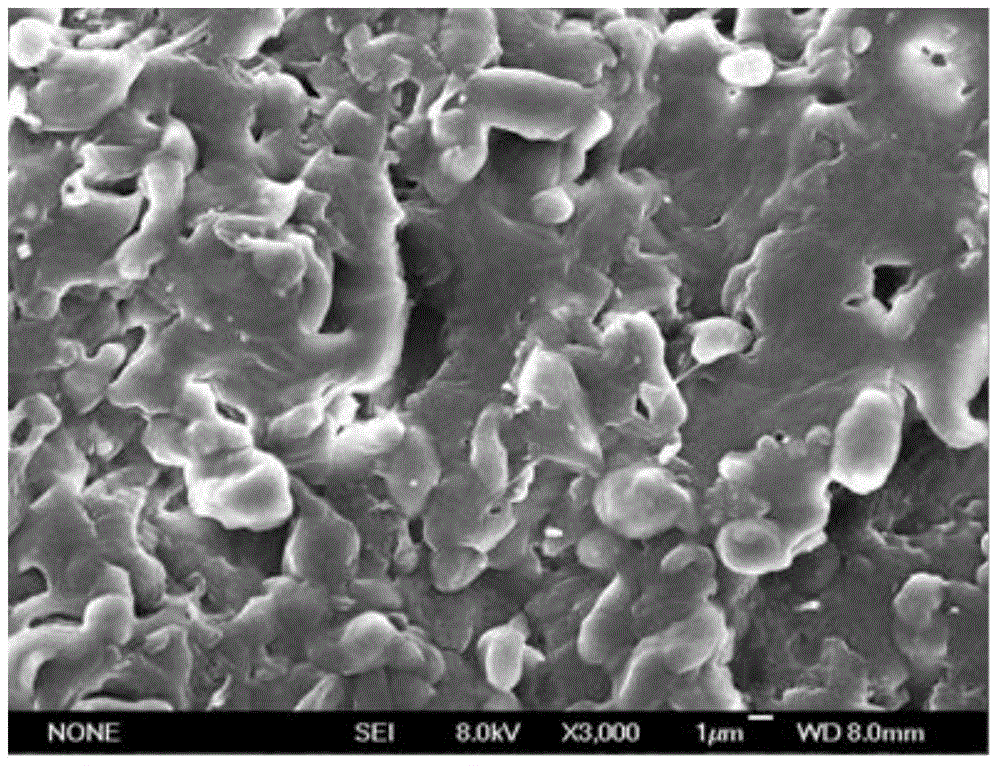

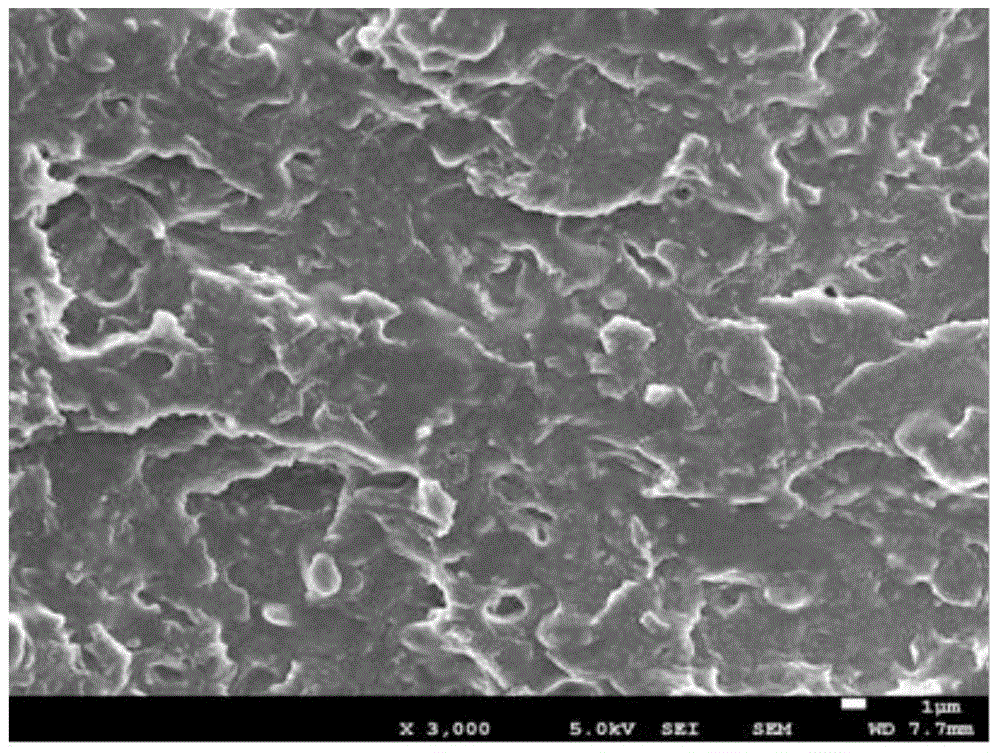

Image

Examples

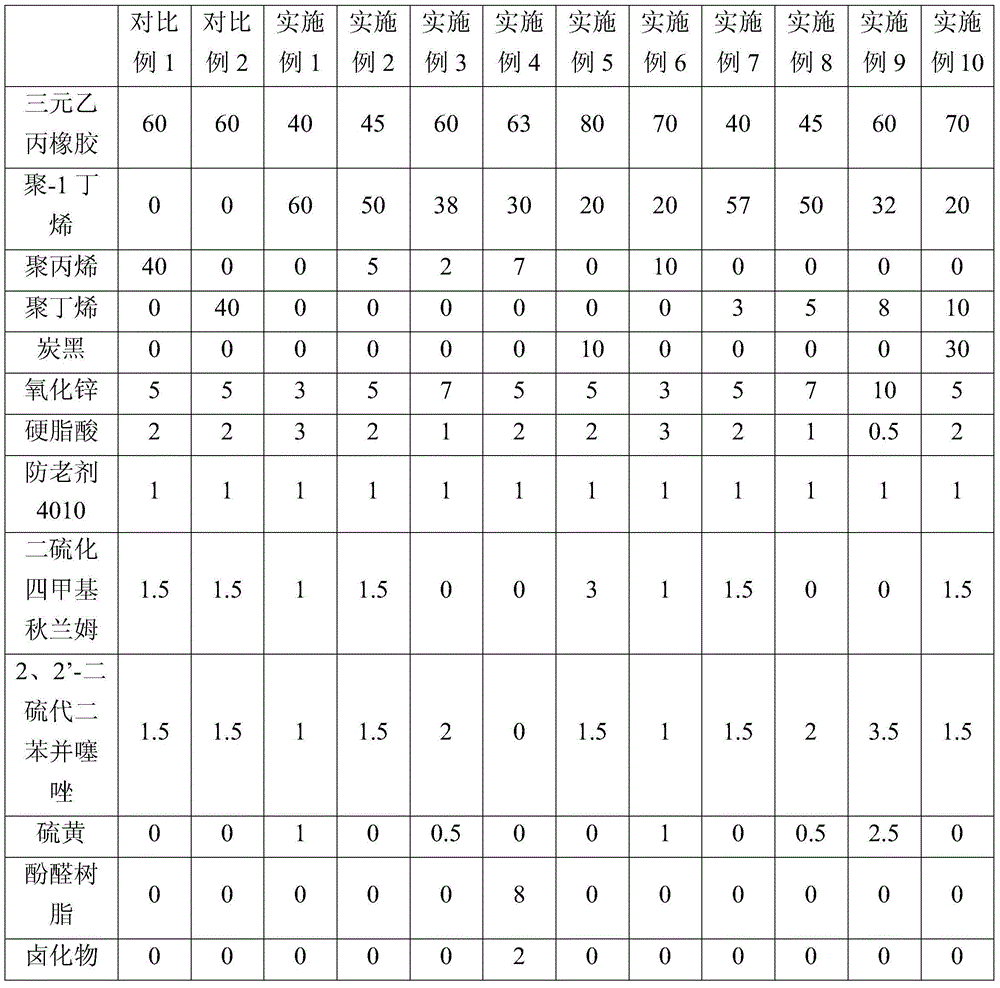

Embodiment 1

[0052] This embodiment provides a kind of EPDM rubber / poly-4-methylpentene-1 dynamically vulcanized thermoplastic elastomer, its components and its preparation method are as follows:

[0053] (1) EPDM rubber of 40 parts by weight, zinc oxide of 3 parts by weight, stearic acid of 3 parts by weight and antioxidant 4010 of 1 part by weight are added in the internal mixer, internal mixer temperature 100 ℃, The rotating speed is 80 rpm, and the time is 15 minutes, and the masterbatch is prepared for use.

[0054] (2) Cut the masterbatch prepared in the first step into pieces for later use. The temperature of the internal mixer is 230°C and the rotating speed is 70r / min. After adding 60 parts by weight of poly-4-methylpentene-1 and melting for 3 minutes, Then add EPDM rubber masterbatch, after blending for 3 minutes, add 1 weight part of tetramethylthiuram disulfide, 1 weight part of 2,2'-dithiodibenzothiazole, 1 weight part Parts of sulfur, discharged after dynamic vulcanization f...

Embodiment 2

[0056] This embodiment provides a kind of EPDM rubber / poly-4-methylpentene-1 / polypropylene dynamically vulcanized thermoplastic elastomer, its components and its preparation method are as follows:

[0057] (1) 45 parts by weight of EPDM rubber, 5 parts by weight of zinc oxide, 2 parts by weight of stearic acid and 1 part by weight of antioxidant 4010 are added to the internal mixer, and the temperature of the internal mixer is 100 ° C, The rotating speed is 80 rpm, and the time is 15 minutes, and the masterbatch is prepared for use.

[0058] (2) The masterbatch prepared in the first step is cut into pieces for subsequent use, the temperature of the internal mixer is 230° C., and the rotating speed is 70 r / min, and 50 parts by weight of poly-4-methylpentene-1 are successively added and melted for 3 minutes, 5 Parts by weight of polypropylene are melted for 2 minutes, then EPDM masterbatch is added, after blending for 3 minutes, 1.5 parts by weight of tetramethylthiuram disulfid...

Embodiment 3

[0060] This embodiment provides a kind of EPDM rubber / poly-4-methylpentene-1 / polypropylene dynamically vulcanized thermoplastic elastomer, its components and its preparation method are as follows:

[0061] (1) 60 parts by weight of EPDM rubber, 7 parts by weight of zinc oxide, 1 part by weight of stearic acid and 1 part by weight of antioxidant 4010 are added to the internal mixer, and the temperature of the internal mixer is 100 ° C, The rotating speed is 80 rpm, and the time is 15 minutes, and the masterbatch is prepared for use.

[0062] (2) The masterbatch prepared in the first step is cut into pieces for subsequent use, the temperature of the internal mixer is 230° C., and the rotating speed is 70 r / min, and 38 parts by weight of poly-4-methylpentene-1 are successively added and melted for 3 minutes, 2 Parts by weight of polypropylene are melted for 2 minutes, then EPDM masterbatch is added, and after blending for 3 minutes, 2 parts by weight of 2,2'-dithiodibenzothiazole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com