Phenolic resin fire hydrant and preparation method thereof

A technology of phenolic resin and fire hydrant, which is applied in the field of fire-fighting equipment based on polymer materials and its preparation, which can solve the problems of fire hydrants being difficult to open and cannot be opened, and achieve the effects of light weight, flexible switching, and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

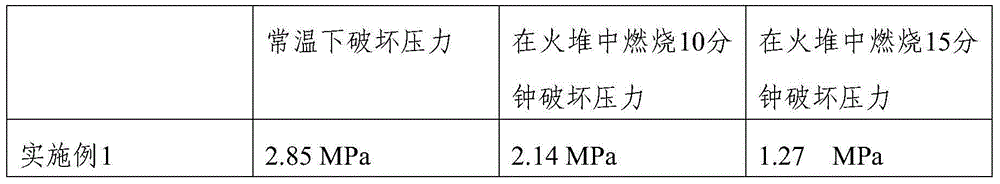

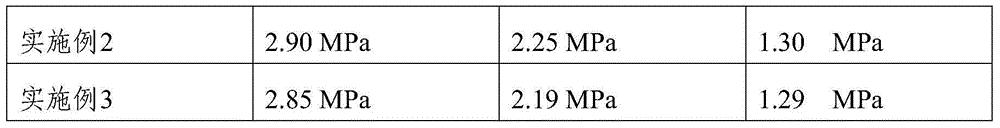

Embodiment 1

[0027] Raw materials: 100 parts of thermoplastic phenolic resin, 43 parts of fire retardant, 5 parts of short glass fiber (purchased from Taian Xianghe Composite Material Co., Ltd., length 3 mm) treated with coupling agent KH-560, curing agent hexamethylene tetra 5 parts of amine, 11 parts of silicon dioxide (2000 mesh) and 12 parts of titanium dioxide as reinforcing agent. The release agent is chlorinated paraffin 50#.

[0028] Fire retardant formula (parts by mass): 6 colloidal antimony pentoxide, 8 decabromodiphenylethane, 7 aluminum dihydrogen phosphate, 5 potassium silicate, 10 hydrotalcite, and 7 ammonium molybdate.

[0029] Preparation:

[0030] (1) First put the fireproofing agent, glass short fiber, curing agent, and reinforcing agent in a high-speed mixer, and stir for 20 minutes to fully disperse and evenly;

[0031] (2) Heat the phenolic resin to 100°C until the material is in a molten state, add the material obtained in (1) and stir evenly, place it on an open m...

Embodiment 2

[0034] Raw materials: 100 parts of phenolic resin (thermoplastic type), 50 parts of fire retardant, 6 parts of short glass fiber treated with coupling agent KH-560, length 3 mm, 6 parts of curing agent hexamethylenetetramine, reinforcing agent: two 12 parts of silicon oxide (2000 mesh) and 12 parts of titanium dioxide. The release agent is chlorinated paraffin 50#.

[0035] Fire retardant formula (parts by mass): 7 colloidal antimony pentoxide, 9 decabromodiphenylethane, 8 aluminum dihydrogen phosphate, 6 potassium silicate, 12 hydrotalcite, and 8 ammonium molybdate.

[0036] Preparation method is with embodiment 1.

Embodiment 3

[0038] Raw materials: 100 parts of phenolic resin (thermoplastic type), 57 parts of fire retardant, 7 parts of short glass fiber treated with coupling agent KH-560, 7 parts of length 3 mm, 8 parts of curing agent hexamethylenetetramine, 2 parts of reinforcing agent Silicon oxide (2000 mesh) 13 parts and titanium dioxide 14. parts. The release agent is chlorinated paraffin 50#.

[0039] Fire retardant formula (parts by mass): colloidal antimony pentoxide 8, decabromodiphenylethane 10, aluminum dihydrogen phosphate 9, potassium silicate 7, hydrotalcite 14, ammonium molybdate 9.

[0040] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com