A kind of preparation method of ultra-low elastic modulus high-strength titanium alloy material

A technology of elastic modulus and titanium alloy, which is applied in the field of biomedical material preparation, can solve unseen problems and achieve the effects of strong repeatability, simple process method and short preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

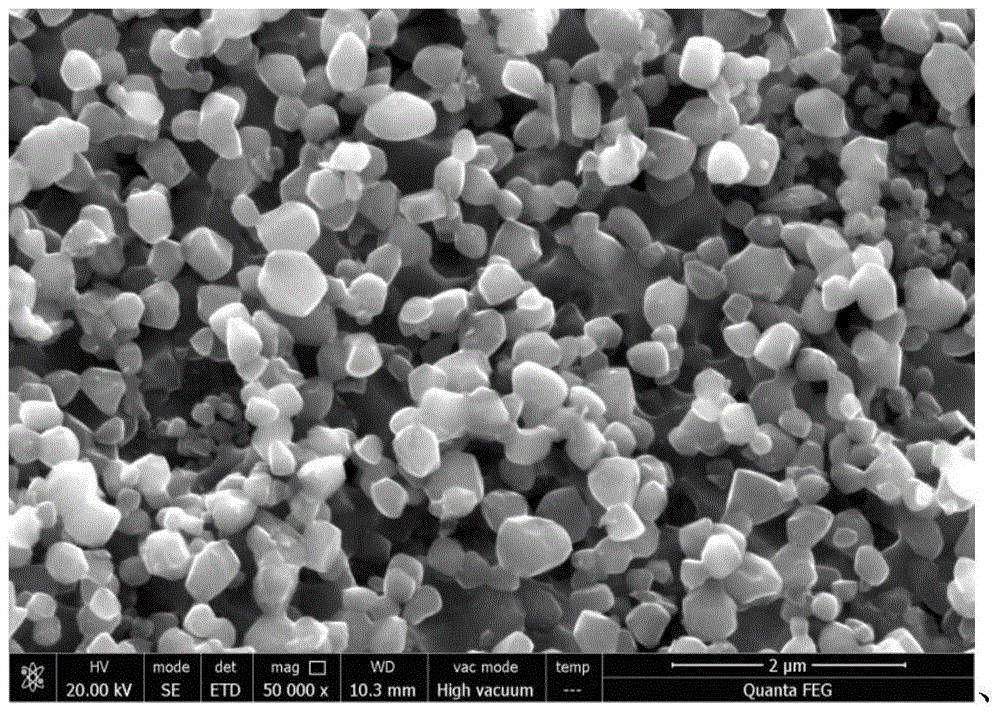

Image

Examples

Embodiment 1

[0016] Ti, Mo and Fe element powders are used as raw materials, the particle size is -500 mesh, and the ratio is carried out according to the nominal composition Ti-8Mo-3Fe (molybdenum equivalent of 16.6wt.%). The mixed powder was subjected to vibratory high-energy ball milling. The ball milling process was carried out under the protection of high-purity argon, with a ball-to-material ratio of 10:1 and a rotational speed of 1000r / min. Composite powder with an average grain size of about 15nm was collected after ball milling for 10h. Put the ball mill powder into a Φ20 stone mill mold, then put the stone mill mold into a discharge plasma sintering furnace, vacuumize the system to 2Pa, add axial pressure to 40MPa, and heat up to 900°C at a speed of 100°C / min , after holding for 5 minutes and then cooling with the furnace, the Ti-8Mo-3Fe alloy bulk material is obtained. After testing, the prepared alloy sample is composed of β+FCC-Ti two phases, and its density is 98.95%, alloy....

Embodiment 2

[0018] Ti and Mo element powders are used as raw materials, the particle size is -325 mesh, and the proportion is carried out according to the nominal composition Ti-6Mo (molybdenum equivalent of 6 wt.%). The mixed powder is subjected to vibratory high-energy ball milling, and the ball milling process is carried out under the protection of high-purity argon, with a ball-to-material ratio of 10:1 and a rotational speed of 1200r / min. After ball milling for 8 hours, the composite powder with an average grain size of about 32nm was collected. Put the ball mill powder into a Φ20 stone mill mold, then put the stone mill mold into a spark plasma sintering furnace, vacuumize the system to 2Pa, add axial pressure to 40MPa, and heat up to 1000℃ at a speed of 100℃ / min , after holding for 5 minutes and then cooling with the furnace, the Ti-6Mo alloy bulk material is obtained. After testing, the density of the prepared sample was 98.49%. The mechanical properties of the sample are: the e...

Embodiment 3

[0020] Ti, Mo and Fe element powders are used as raw materials, the particle size is -500 mesh, and the proportion is carried out according to the nominal composition Ti-8Mo-9Fe (molybdenum equivalent of 33.7 wt.%). The mixed powder was subjected to vibratory high-energy ball milling, and the ball milling process was carried out under the protection of high-purity argon, with a ball-to-material ratio of 15:1 and a rotational speed of 800r / min. After ball milling for 12 hours, the composite powder with an average grain size of about 9nm was collected. Put the ball mill powder into a Φ20 stone mill mold, then put the stone mill mold into a spark plasma sintering furnace, vacuumize the system to 2Pa, add axial pressure to 40MPa, and heat up to 850℃ at a speed of 100℃ / min , After holding for 5 minutes and then cooling with the furnace, a Ti-8Mo-9Fe alloy bulk material is obtained. After testing, the prepared alloy sample is composed of β+FCC-Ti and a small amount of TiFe phase, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com