Etching liquid composition and etching method

A technology of composition and etching solution, which is applied in the field of etching solution composition, and can solve problems such as unfavorable process, reduction of metal solubility, small particle residue, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026]

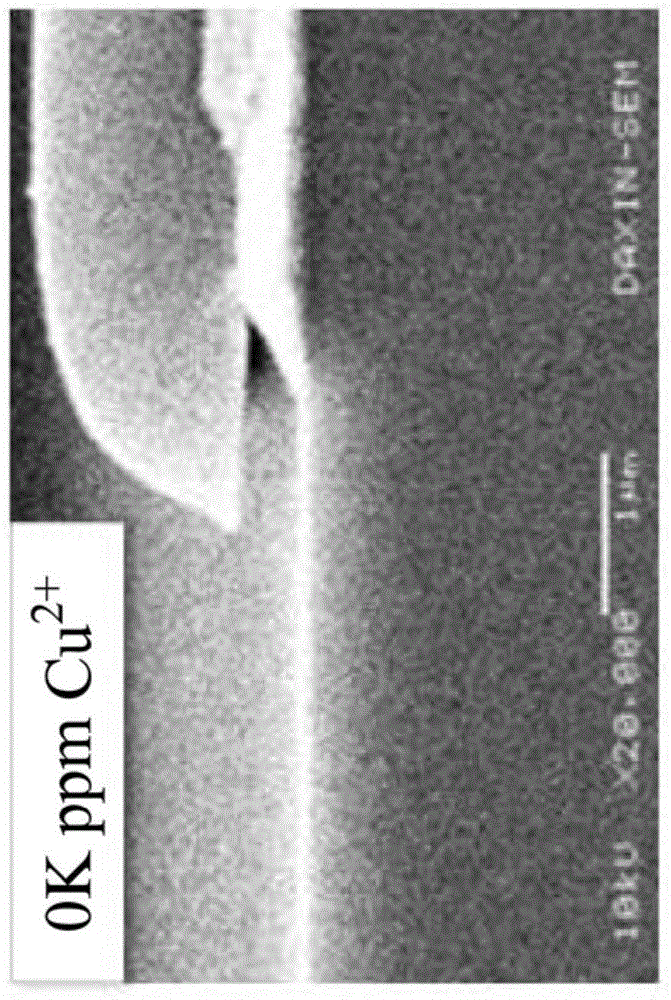

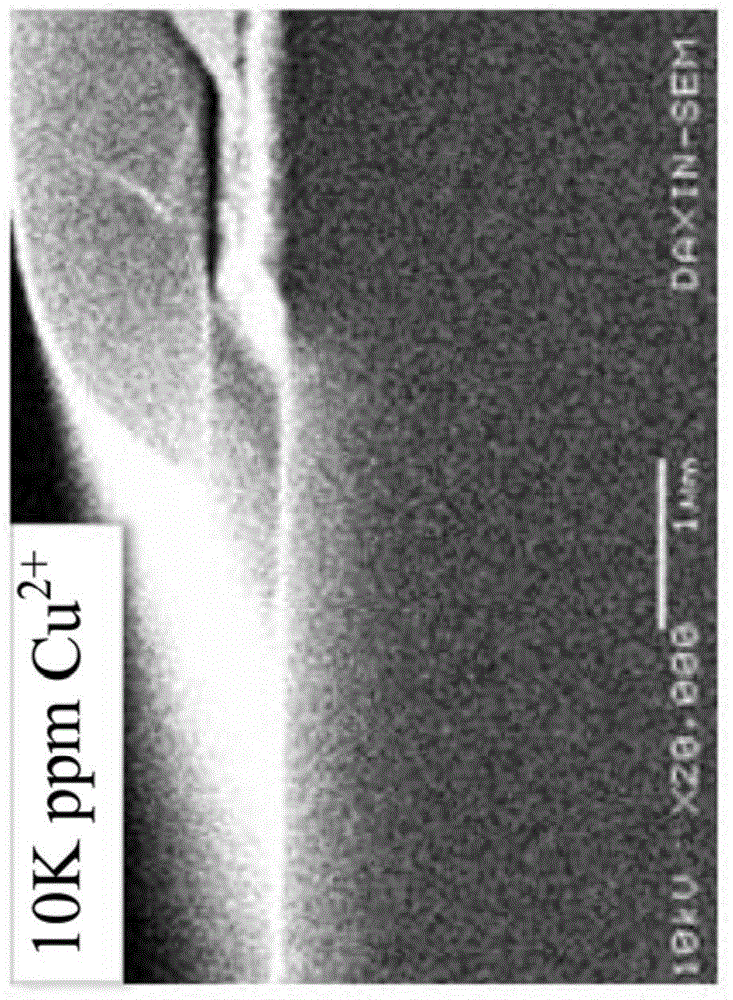

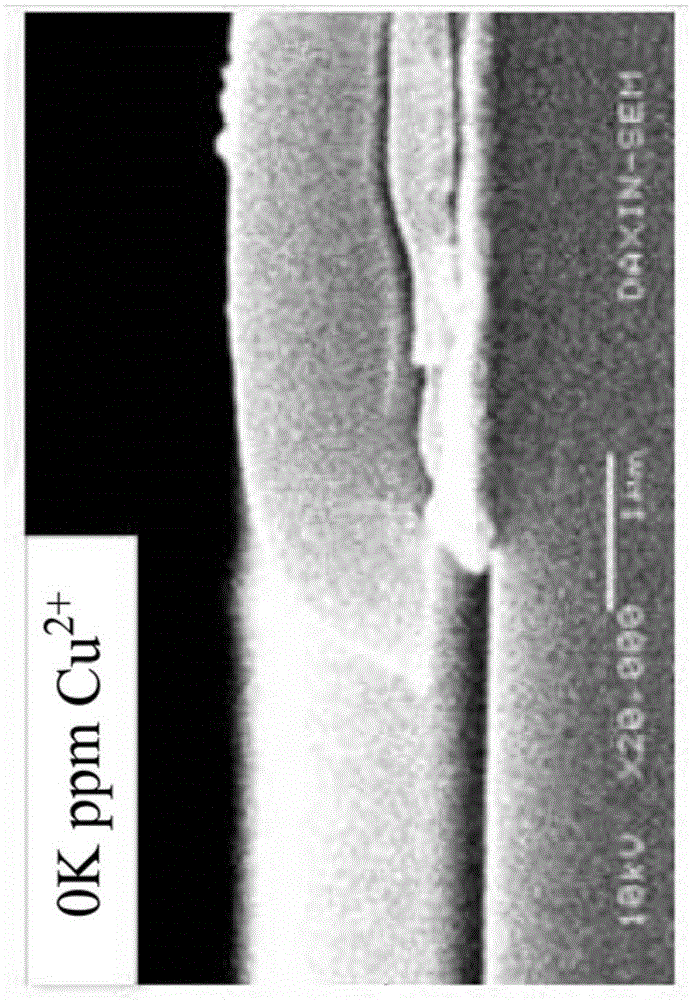

[0027] An etchant composition for etching multilayer films containing copper and molybdenum, specifically, can be used for etching copper / molybdenum, copper / molybdenum nitride, molybdenum / copper / molybdenum nitride, molybdenum nitride / copper / molybdenum nitride and molybdenum nitride / copper / molybdenum and other multi-layer films.

[0028] The etchant composition comprises hydrogen peroxide, a first organic acid or its salts, a second organic acid or its salts and an alcohol amine compound, wherein the hydrogen peroxide, the first organic acid or its salts and the second organic acid Or its salts are used to provide the etching ability to copper-containing and molybdenum-containing multilayer films. If only the first organic acid or its salts are used, there will be a defect that the CD difference (critical dimension bias, CD bias) is too small, And when the copper is high, it will not be possible to etch, or it will not be possible to etch out the CD difference. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com