Coated magnesium alloy bone nail, bone plate and cancellous bone screw and preparation method thereof

A technology of magnesium alloy and cancellous bone, applied in coating, metal material coating technology, medical science and other directions, can solve the problem of unreported fluorapatite coating and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

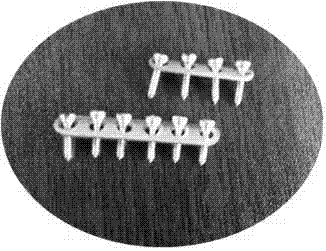

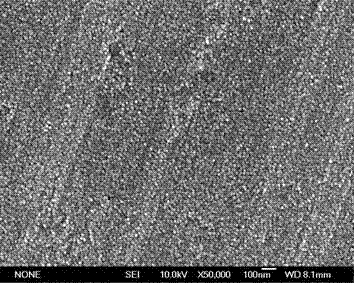

[0023] A coated magnesium alloy bone nail and bone plate, the magnesium alloy is composed of Mg, Zn, and Zr with a purity greater than 99.99 wt.%, and the mass percentages of each component are: Zn is 3%, Zr is 0.6%, Mg for the margin.

[0024] The preparation method of the coated magnesium alloy bone nail and bone plate is as follows:

[0025] 1) Add Mg, Zn and Mg-30 wt.% Zr master alloy into the graphite crucible, and evacuate to 1×10 -2 Pa, pass through argon protection, heat to 780°C and keep it warm for 20 minutes, then fully stir at a speed of 8r / s for 8min, then start to cool down, pour the temperature into a crystallizer after the temperature drops to 650°C, and obtain a round ingot with a diameter of 40mm;

[0026] 2) Place the above-mentioned round ingot in an air furnace, homogenize and anneal at 300°C for 36 hours, then raise the temperature to 510°C for solid solution for 2 hours, and then quench into warm water at 30-50°C;

[0027] 3) Hot extrusion is carried o...

Embodiment 2

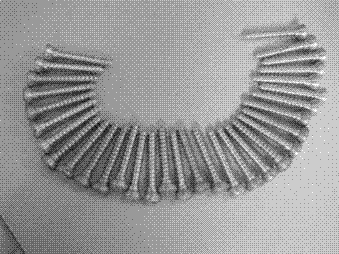

[0033] A coated magnesium alloy cancellous bone screw, the magnesium alloy is composed of Mg, Zn, and Zr with a purity greater than 99.99 wt.%, and the mass percentages of each component are: Zn is 3%, Zr is 0.6%, and Mg is margin.

[0034] The preparation method of the coated magnesium alloy cancellous bone screw, the steps are as follows:

[0035]1) Add Mg, Zn and Mg-30 wt.% Zr master alloy into the graphite crucible, and evacuate to 1×10 -2 Pa, pass through argon protection, heat to 780°C and keep it warm for 20 minutes, then fully stir at a speed of 8r / s for 8min, then start to cool down, pour the temperature into a crystallizer after the temperature drops to 650°C, and obtain a round ingot with a diameter of 40mm;

[0036] 2) Place the above round ingot in an air furnace, homogenize and anneal at 300°C for 36 hours, then raise the temperature to 510°C for 2 hours, and then quench it into warm water at 30-50°C;

[0037] 3) Hot extrusion was performed at 300°C with an ext...

Embodiment 3

[0043] A coated magnesium alloy bone nail and bone plate, the magnesium alloy is composed of Mg, Zn, Zr, and Ca with a purity greater than 99.99 wt.%, and the mass percentage of each component is: Zn is 3%, Zr is 0.6% , Ca is 0.1%, and Mg is the balance.

[0044] The preparation method of the coated magnesium alloy bone nail and bone plate is as follows:

[0045] 1) Add Mg, Zn and Mg-30 wt.% Zr, Mg-30 wt.%Ca master alloy into the graphite crucible, and evacuate to 1×10 -2 Pa, pass through argon protection, heat to 780°C and keep it warm for 20 minutes, then fully stir at a speed of 8r / s for 8min, then start to cool down, pour the temperature into a crystallizer after the temperature drops to 650°C, and obtain a round ingot with a diameter of 40mm;

[0046] 2) Place the above round ingot in an air furnace, homogenize and anneal at 300°C for 36 hours, then raise the temperature to 510°C for solid solution for 3 hours, and then quench into warm water at 30-50°C;

[0047] 3) Hot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com