Efficient c 3 no 4 In situ conversion preparation method of -cds composite photocatalytic material

A composite photocatalytic and high-efficiency technology is applied in the field of in-situ transformation and preparation of high-efficiency C3N4-CdS composite photocatalytic materials to achieve the effects of enhanced photocatalytic hydrogen production performance, uniform particle size, and good interfacial interaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

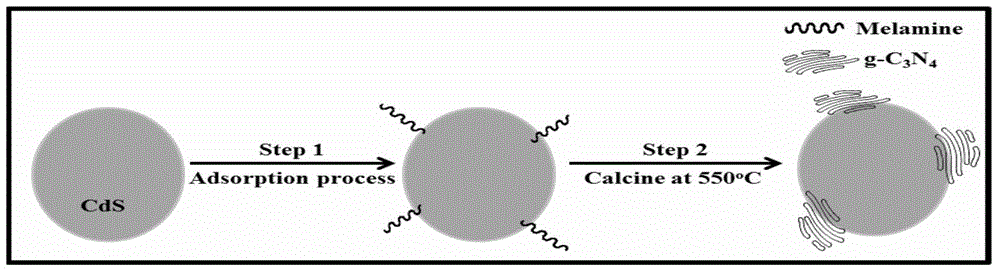

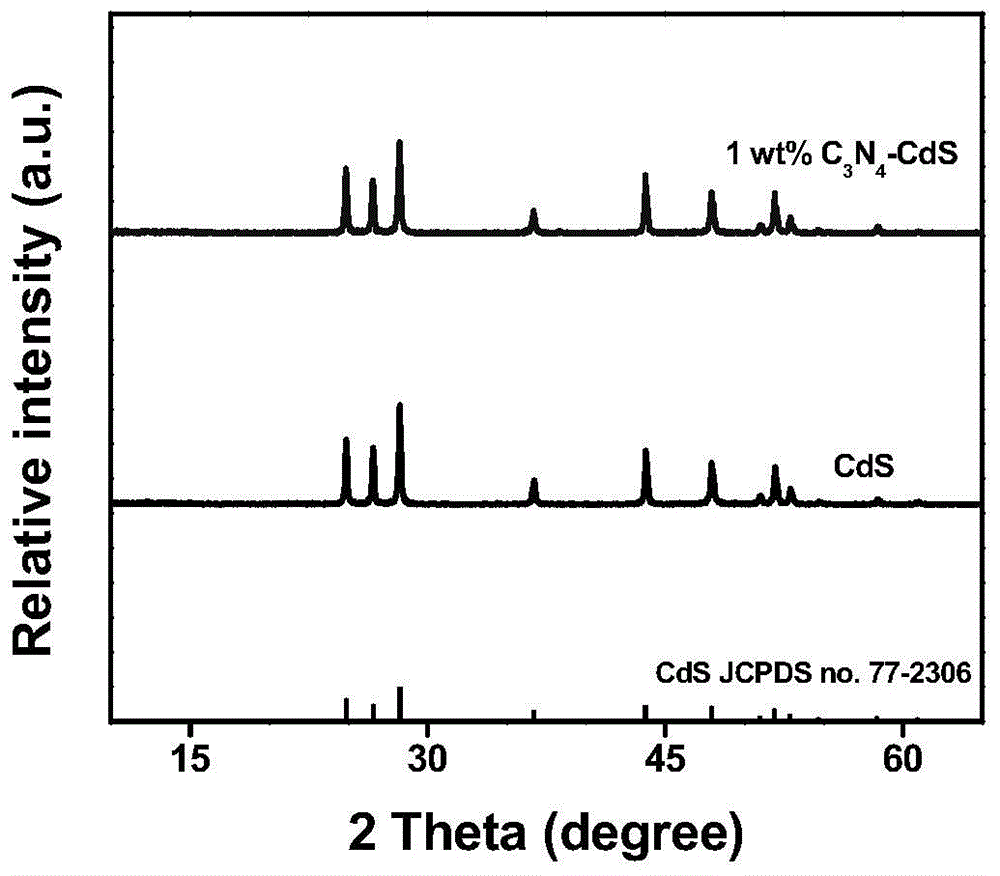

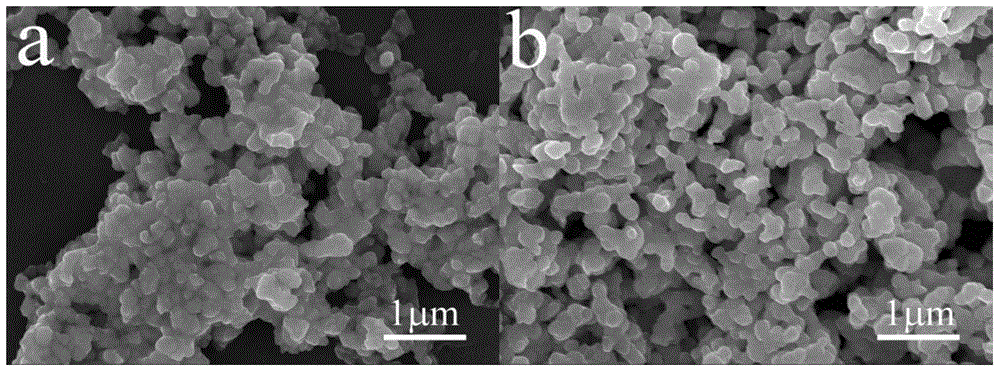

[0027] Efficient C 3 N 4 -CdS composite photocatalytic material in-situ conversion preparation process is as follows: 1) Disperse melamine in deionized water to form a uniform solution, wherein the concentration of melamine is 0.002g / mL; 2) Disperse 0.2g cadmium sulfide powder uniformly ) in 9mL melamine solution prepared in 85°C constant temperature water bath for 2h, so that melamine is evenly adsorbed on the surface of cadmium sulfide powder; Dry at a constant temperature of 80°C in the box to completely evaporate the water and finally obtain melamine-modified cadmium sulfide powder; 4) place the cadmium sulfide powder evenly loaded with melamine on the surface obtained in step 3) in a tube furnace, and in a nitrogen atmosphere Calcined at 550°C for 0.5h to obtain C 3 N 4 The content is 1wt% of C 3 N 4 -CdS composite photocatalytic material.

[0028] figure 1 C in Example 1 3 N 4 -Schematic diagram of the in situ conversion preparation process of CdS photocatalytic...

Embodiment 2

[0036] In order to examine the effect of melamine concentration on C 3 N 4 -Influence of photocatalytic performance of CdS photocatalyst, in addition to different concentration of melamine, other reaction conditions such as water bath reaction temperature (85°C), stirring time (2h), drying temperature (80°C), calcination temperature (550°C), calcination time (0.5h) etc. are all identical with embodiment 1. The results showed that: when the concentration of melamine was 0.0001g / mL, the obtained C 3 N 4 C in -CdS photocatalyst 3 N 4 The content is low, and the photocatalytic hydrogen production performance is not significantly improved, and its performance is 2310 μmol h -1 g -1 ; When the concentration of melamine was 0.0005, 0.002 and 0.05g / mL, the obtained C 3 N 4 The photocatalytic performance of -CdS photocatalyst is significantly improved, all at 5000-5500μmol h -1 g -1 ; When the concentration of melamine solution was 0.1g / mL, because the melamine solid could no...

Embodiment 3

[0038] To test the effect of water bath temperature on C 3 N 4 -Influence of photocatalytic performance of CdS photocatalyst, in addition to different water bath temperature, other reaction conditions such as melamine concentration (0.002g / mL), stirring time (2h), drying temperature (80°C), calcination temperature (550°C), calcination Time (0.5h) etc. are all identical with embodiment 1. The results show that: when the water bath temperature of the melamine solution is 30°C, the melamine solid cannot be dissolved basically, so the evenly distributed C on the surface cannot be obtained. 3 N 4 -CdS photocatalyst; when the water bath temperature of the melamine solution is 60, 85 and 100°C, a uniform melamine solution can be obtained, and thus a uniform distribution of C on the surface can be obtained 3 N 4 -CdS photocatalyst. Therefore, in C 3 N 4 - During the preparation of the CdS photocatalyst, the optimum temperature of the water bath is 60-100°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com