Hydrogenation catalyst for polymer containing olefinic unsaturated bond, preparation method thereof and hydrogenation reaction method

A hydrogenation catalyst and hydrogenation reaction technology, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of low activity and reaction efficiency, and achieve The effects of high hydrogenation reaction efficiency, good hydrogenation selectivity, and high hydrogenation catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

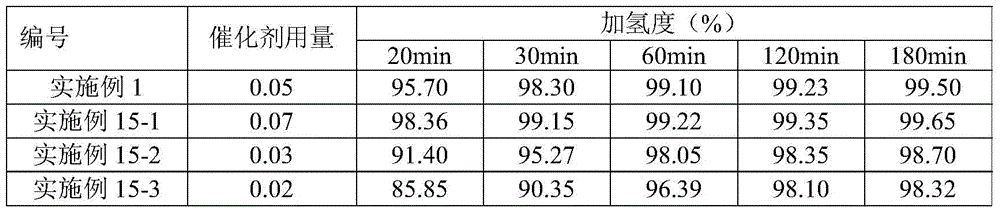

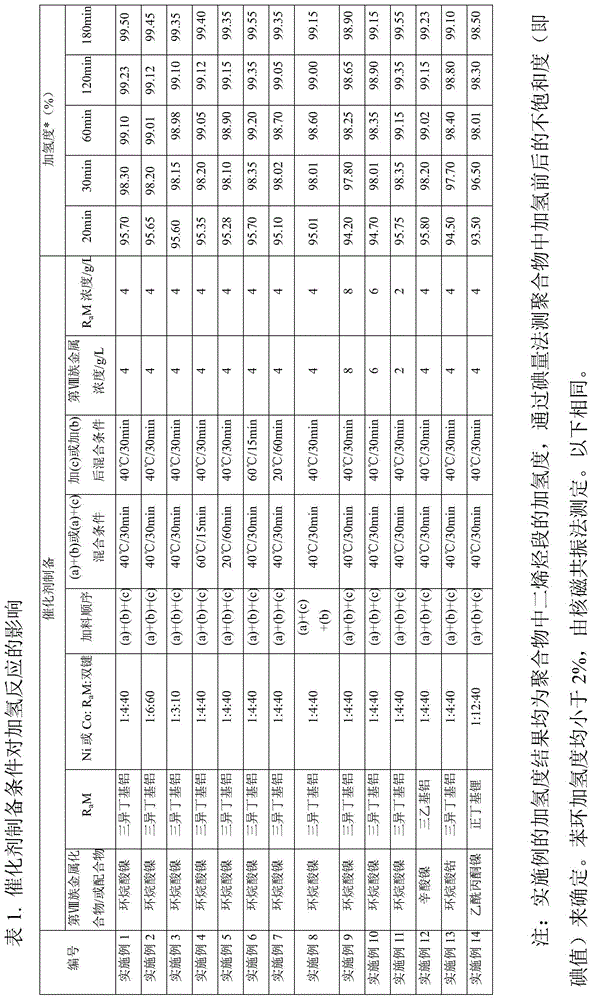

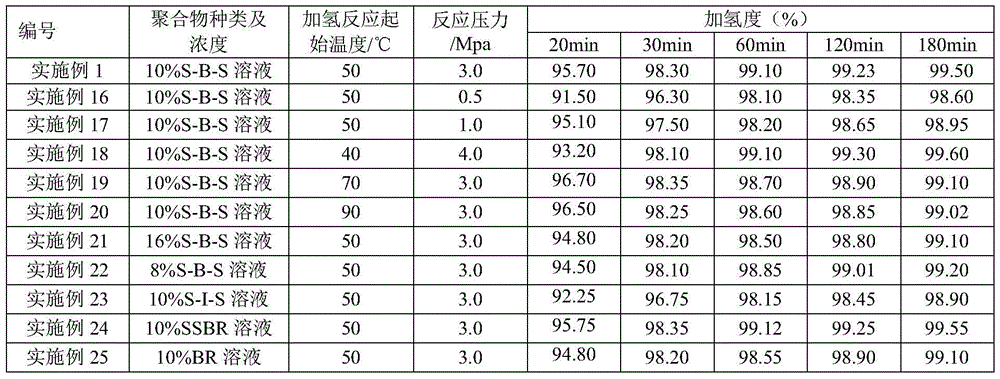

Examples

preparation example Construction

[0044] The present invention also provides a preparation method of the above-mentioned hydrogenation catalyst, wherein the preparation method comprises:

[0045] First mix (a) and (b) evenly to obtain (a+b) mixed solution, then mix (c) and (a+b) mixed solution evenly, the above mixing process makes components (a), (b) and (c) undergo an aging reaction,

[0046] Among them, the mixing time of (a) and (b) is preferably 5-120 minutes, the mixing temperature is 0-100°C, the preferred mixing time is 10-60 minutes, and the mixing temperature is 20-70°C; preferably (c) and ( a+b) The mixing time of the mixture is 2-90 minutes, the mixing temperature is 0-100°C, preferably the mixing time is 5-60 minutes, and the mixing temperature is 20-70°C;

[0047] or

[0048] First mix (a) and (c) evenly to obtain (a+c) mixed solution, then mix (b) and (a+c) mixed solution evenly, the above mixing process makes components (a), (b) and (c) undergo an aging reaction,

[0049] Among them, prefer...

Embodiment 1

[0074] (1) Preparation of polymers containing olefinic unsaturated bonds

[0075] A 500L jacketed stirred reactor was fully replaced with purified nitrogen, 250L cyclohexane and hexane mixed solvent (the weight percentage of cyclohexane in the mixed solvent was 87wt%) and 3.6L refined styrene were added, and n-butyllithium and tetrahydrofuran were added (the molar ratio of tetrahydrofuran to n-butyllithium in the mixture is 36:1), react at 50-60°C for 30 minutes, continue to add 25L of refined butadiene to react for 30 minutes, and then add 3.6L of refined styrene to react After 40 minutes, isopropanol was added to terminate the reaction after the reaction was completed, and the molar ratio of isopropanol to n-butyllithium was 1:1. Here, the concentration of styrene-butadiene-styrene block copolymer (S-B-S) is about 10wt% based on the whole polymerization system, the number average molecular weight of the block copolymer is 66000, styrene and butadiene monomer The weight rati...

Embodiment 2

[0082]Polymer hydrogenation reaction was carried out according to the method of Example 1, the difference is that in step (2), Ni:Al:double bond=1:6:60. The hydrogenation reaction results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com