Method for preparing calcium copper titanium oxide compound powder

A calcium-copper-titanium oxide compound technology is applied in the field of preparing calcium-copper-titanium oxide compound powder by a new low-cost chemical method, which can solve the problems of large environmental pollution, high calcination temperature, high raw material cost, etc., and achieves good dispersibility and simplification. Preparation process, uniform effect of ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

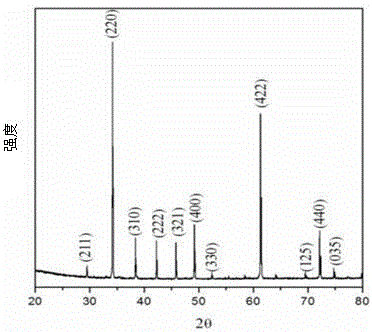

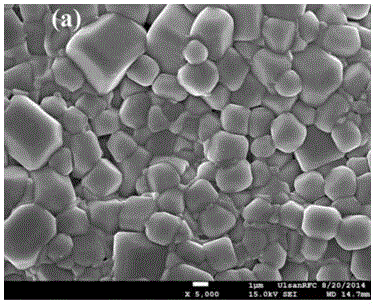

Embodiment 1

[0013] Calcium nitrate and copper nitrate of analytical grade are used for weighing and proportioning in a molar ratio of 1:3, dissolved in ethylene glycol monomethyl ether, and the mass of ethylene glycol monomethyl ether is the mass of analytical pure calcium nitrate and analytical pure copper nitrate 3 times of the sum to obtain a homogeneous solution (solution A). Based on the calcium nitrate added above, measure the corresponding amount of titanium dioxide with a measuring cylinder according to the Ca:Ti molar ratio of 1:4 and dissolve it in liquid A. The volume of liquid A is 3 times the volume of titanium dioxide. Stir fully to make the titanium dioxide evenly dissolved In liquid A, liquid B is formed. Heat liquid B to 70°C and stir while heating at a stirring speed of 100 rpm to completely evaporate the organic solvent until spontaneous combustion occurs. Spontaneous combustion produces a large amount of gas at room temperature, and a powder with good dispersibility i...

Embodiment 2

[0015] Calcium nitrate and copper nitrate of analytical grade are used for weighing and proportioning in a molar ratio of 1:3, dissolved in ethylene glycol monomethyl ether, and the mass of ethylene glycol monomethyl ether is the mass of analytical pure calcium nitrate and analytical pure copper nitrate 8 times of the sum to obtain a homogeneous solution (solution A). Based on the calcium nitrate added above, measure the corresponding amount of titanium dioxide with a measuring cylinder according to the Ca:Ti molar ratio of 1:4 and dissolve it in liquid A. The volume of liquid A is 12 times the volume of titanium dioxide. Stir fully to make the titanium dioxide dissolve evenly In liquid A, liquid B is formed. Heat to 80°C and stir while heating at a stirring speed of 60 rpm to completely evaporate the organic solvent until spontaneous combustion occurs. Spontaneous combustion produces a large amount of gas at room temperature, and a powder with good dispersibility is obtained...

Embodiment 3

[0017] Calcium nitrate and copper nitrate of analytical grade are used for weighing and proportioning in a molar ratio of 1:3, dissolved in ethylene glycol monomethyl ether, and the mass of ethylene glycol monomethyl ether is the mass of analytical pure calcium nitrate and analytical pure copper nitrate 12 times of the sum to obtain a homogeneous solution (solution A). Based on the calcium nitrate added above, according to the Ca:Ti molar ratio of 1:4, use a measuring cylinder to measure the corresponding amount of titanium dioxide and dissolve it in liquid A. The volume of liquid A is 6 times the volume of titanium dioxide. Stir fully to make the titanium dioxide evenly dissolved. In liquid A, liquid B is formed. Heat liquid B to 90°C and stir while heating at a stirring speed of 140 rpm to completely evaporate the organic solvent until spontaneous combustion occurs. Spontaneous combustion produces a large amount of gas at room temperature, and a powder with good dispersibil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com