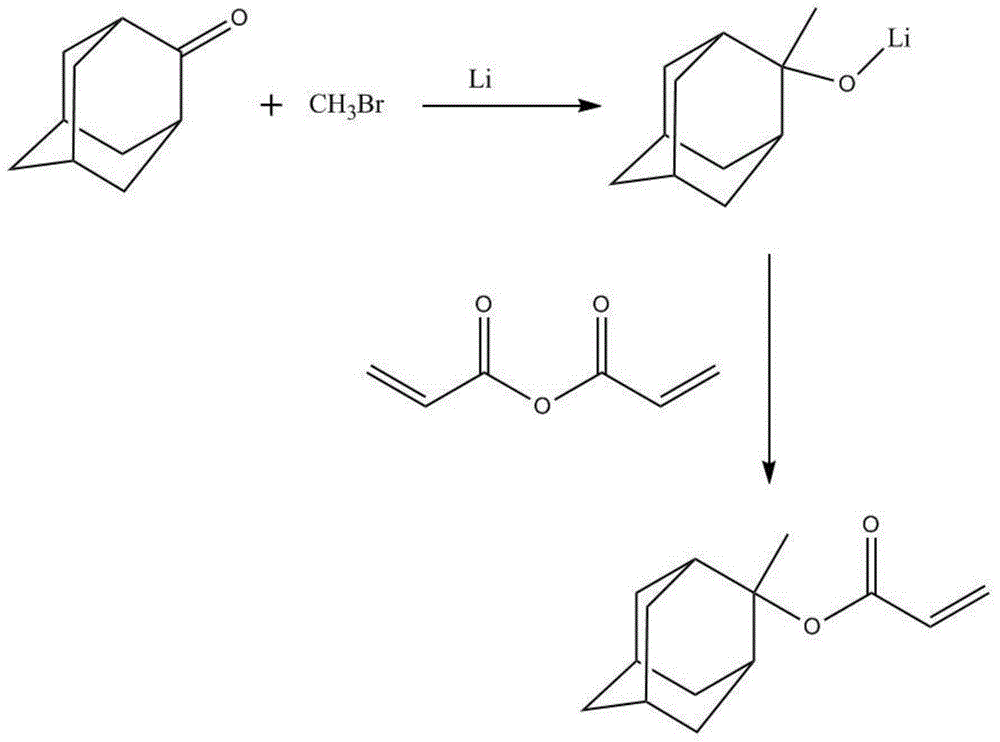

Preparation method of 2-methyl-2-adamantyl acrylate

A technology of adamantanol acrylate and adamantanone is applied in the field of preparation of 2-methyl-2-adamantanol acrylate and can solve the problems of high corrosiveness, strict production requirements, difficulty in storage and production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053]Step 1. Dissolve 120g of adamantanone in 272ml of anhydrous tetrahydrofuran, and add 192g of 59.37% (wt / wt) methyl bromide in tetrahydrofuran under stirring (methane bromide is passed into tetrahydrofuran at -5°C--0°C), Dissolved and then used.

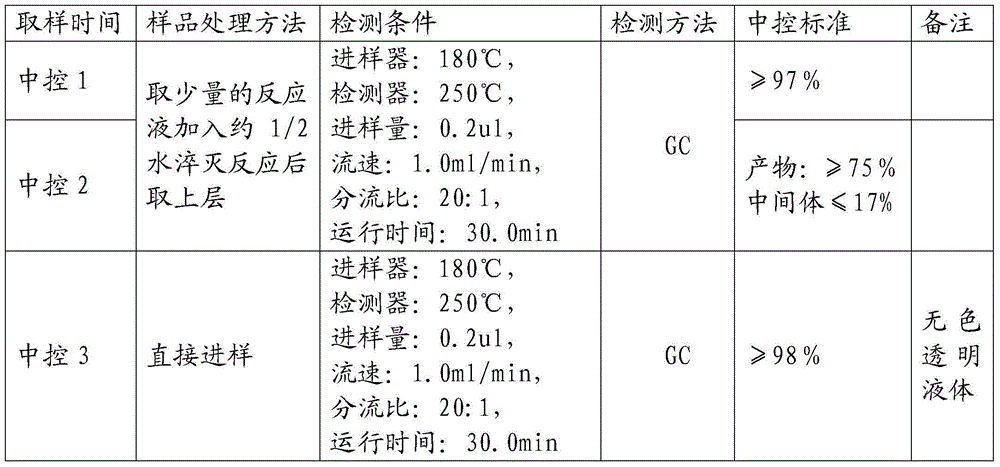

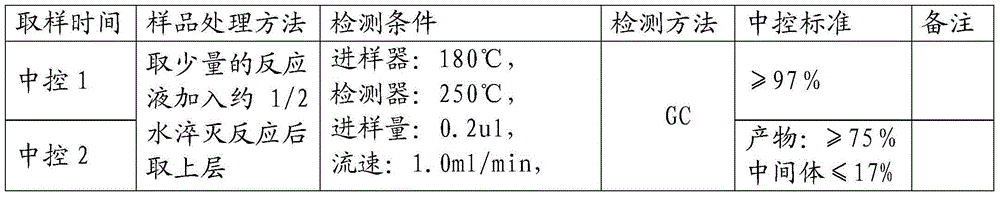

[0054] Step 2: Add 13g of lithium metal and 300ml of anhydrous tetrahydrofuran (moisture content less than 200ppm) into a 1000ml reaction bottle with mechanical stirring, drop the temperature to -5°C to 0°C while stirring, and start adding the above mixed solution for about 2 hours After finishing, control the temperature at 5°C to 15°C. After dripping, keep it warm for 1 hour, then take a sample and add water to quench the reaction, then TLC (PE:EA=10:1, iodine color development, water soaking), and send the sample to GC after passing the test ( Central control 1), cool down to -10°C ~ -8°C.

[0055] Step 3: Add 2 g of phenothiazine and stir for 10 min.

[0056] Step 4: Start to drop 120g of acrylic anhydride to control the d...

Embodiment 2

[0061] Step 1. Dissolve 150g of adamantanone in 375ml of anhydrous tetrahydrofuran, and add it into the tetrahydrofuran solution of methyl bromide under stirring (180g of methyl bromide is poured into 315ml of tetrahydrofuran at -5°C--0°C), dissolve and set aside for use.

[0062] Step 2. Add 19.6g of lithium metal and 330ml of anhydrous tetrahydrofuran (moisture content less than 200ppm) into a 1000ml reaction bottle with mechanical stirring, and drop the temperature to -5°C to 0°C while stirring, and start adding the above mixed solution for about 2.5 hours After dripping, control the temperature at 5°C-15°C. After dripping, keep warm for 1.5 hours, then take a sample and add water to quench the reaction, then TLC (PE:EA=10:1, iodine color development, soaking in water), and send the sample to GC after passing the test (Central control 1), cool down to -10°C to -5°C.

[0063] Step 3, adding 4.5 g of phenothiazine and stirring for 20 min.

[0064] Step 4: Start adding 176g o...

Embodiment 3

[0070] Step 1. Dissolve 150g of adamantanone in 300ml of anhydrous benzene, and add 178g of 65% (wt / wt) methyl bromide in benzene solution under stirring (the methyl bromide is introduced into anhydrous benzene at -5°C--0°C ), ready to use after dissolving.

[0071] Step 2. Add 13g of lithium metal and 220ml of anhydrous benzene into a 1000ml reaction bottle with mechanical stirring, and drop the temperature to -5°C to 0°C while stirring, and start adding the above mixed solution dropwise for about 3 hours. Control the temperature at 5 ℃ ~ 15 ℃, keep warm for 1 hour after dripping, take samples and add water to quench the reaction, TLC (PE:EA=10:1, iodine color development, water soaking), and send samples to GC after passing the test (central control 1), Cool down to -10°C to -8°C.

[0072] Step 3: Add 1 g of phenothiazine and stir for 10 min.

[0073] Step 4: Start to drop 75g of acrylic anhydride to control the rate of addition and control the temperature at -10°C to -5°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com