A Yeast Strain with Low Protease A Excretion Under Stress Conditions

A technology of Saccharomyces cerevisiae strain and protease, which is applied in the field of bioengineering to achieve the effects of improving foam stability and reducing enzyme activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

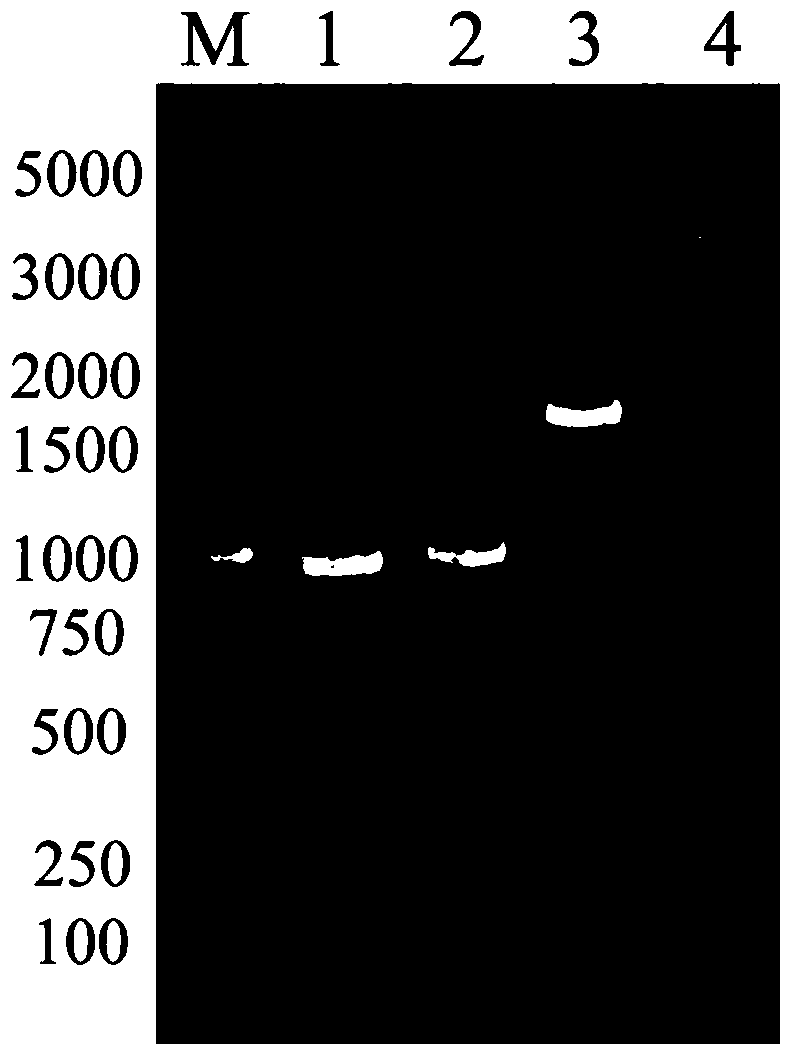

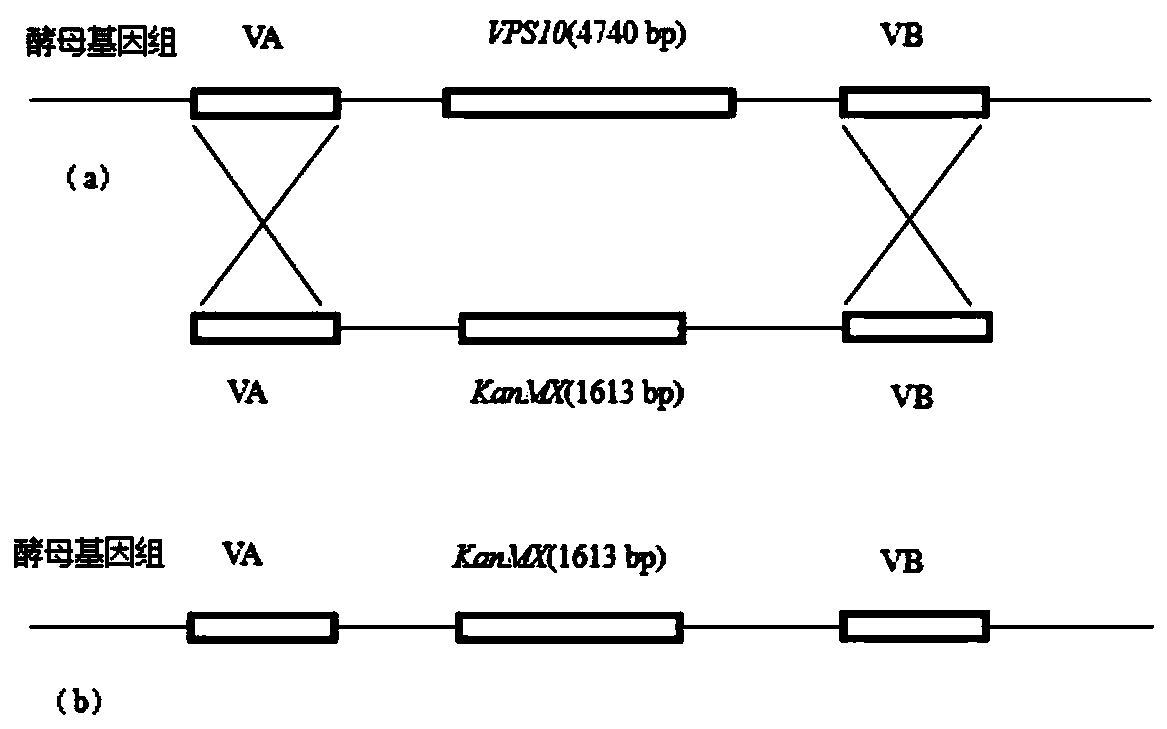

[0043] Example 1: Construction of deletion mutant strains

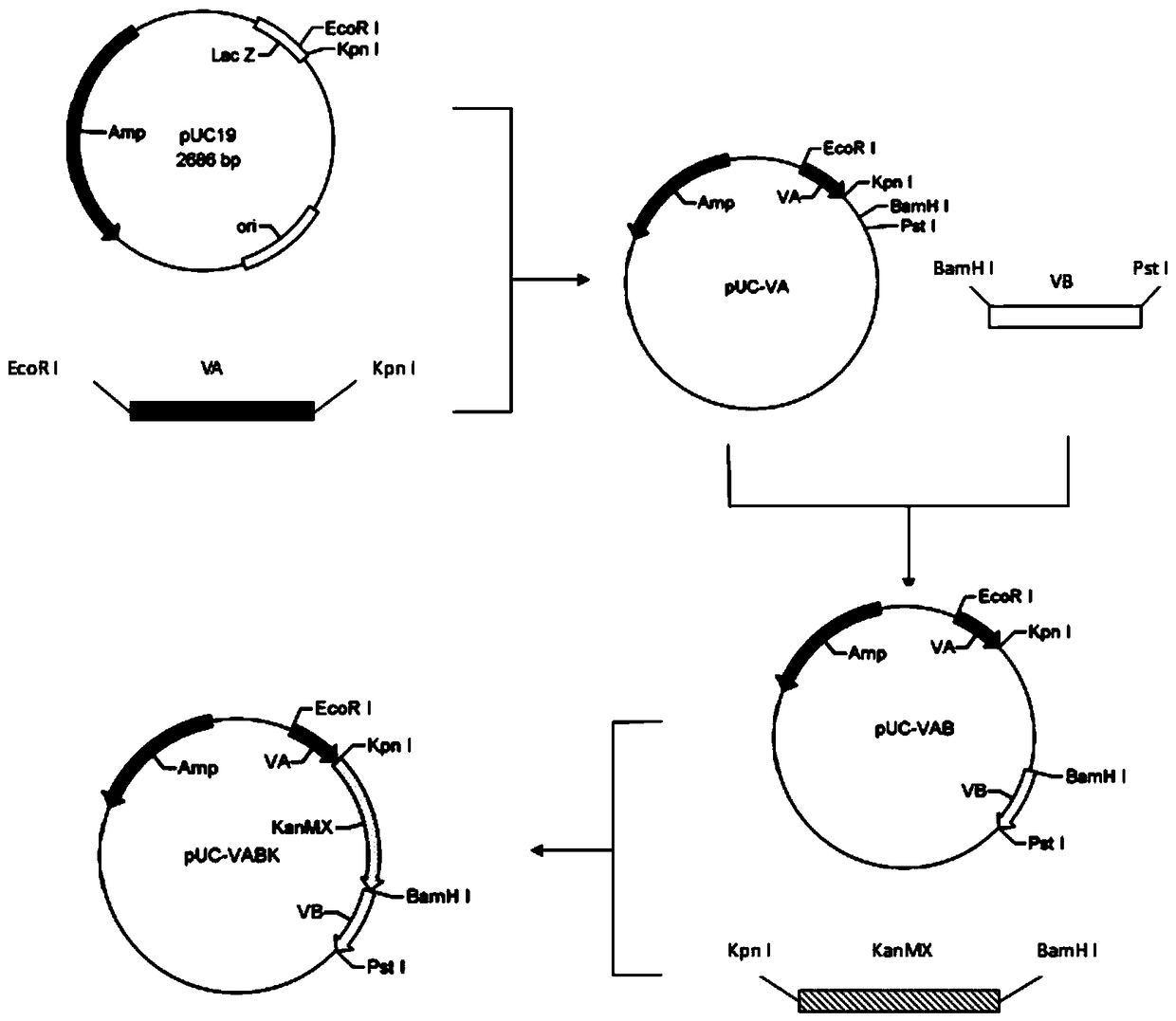

[0044](1) Construction of pUC-VABK plasmid

[0045] The construction process of the recombinant plasmid pUC-VABK is as follows: figure 1 shown.

[0046] ①Using the total DNA of the yeast strain W303-1A as a template, the upstream sequence VA of the VPS10 gene was amplified by PCR;

[0047] Upstream primer VA-U: CCG GAATTC GAGTTTATGAGAAGGTTGGAGG (SEQ ID NO: 3)

[0048] Downstream primer VA-D: CGG GGTACC AAAGACCCGAGTAGTTGGAG (SEQ ID NO: 4)

[0049] The underlined part is the enzyme cleavage site;

[0050] PCR reaction conditions: 95°C for 5min; 94°C for 45s; 63°C for 1min; 72°C for 60s, 30 cycles; 72°C for 10min, 0.8% agarose gel electrophoresis to identify the amplified product;

[0051] PCR reaction system (20μL)

[0052]

[0053] The PCR product was connected to the pUC19 plasmid vector containing Amp resistance to obtain the recombinant plasmid pUC-VA.

[0054] ②Using the total DNA of the yeast strain ...

Embodiment 2

[0075] Embodiment 2: Construction of overexpression strain

[0076] (1) Construction of Yep-PVK plasmid

[0077] The construction process of the recombinant plasmid Yep-PVK is as follows: Figure 5 shown.

[0078] ① Use the pPGK1 plasmid as a template to amplify the strong promoter PGK1p-PGK1t gene fragment by PCR;

[0079] Upstream primer PGK-U: CGC GGATCC TCTAACTGAT CTATCCAAAACTGA (SEQ ID NO: 13)

[0080] Downstream primer PGK-D: CGC GTC GAC TAACGAACGCAGAATTTTC (SEQ ID NO: 14)

[0081] The underlined part is the enzyme cutting site

[0082] PCR reaction conditions: 95°C for 5min; 94°C for 45s; 61°C for 1min; 72°C for 100s, 30 cycles; 72°C for 10min, 0.8% agarose gel electrophoresis to identify the amplified product;

[0083] The PCR product was connected to the expression vector YEP352 to obtain the recombinant plasmid Yep-P.

[0084] ② Using the total DNA of the yeast strain W303-1A as a template, the VPS10 gene was amplified by PCR;

[0085] Upstream primer VPS1...

Embodiment 3

[0102]Embodiment 3: beer fermentation experiment

[0103] Taking the recombinant strains obtained in Examples 1 and 2 and the starting strain W303-1A as experimental objects,

[0104] (1) Seed cultivation

[0105] 1) Activation of strains: The preserved strains were transferred to YEPD inclined test tubes at 30°C for two days of activation.

[0106] 2) Primary seed culture: Take a loop of slant bacteria, inoculate it into a test tube containing 5 mL of wort medium, and culture it at 30° C. and 180 rpm for 14 hours.

[0107] 3) Secondary seed cultivation: The primary seed liquid was transferred into a 150mL Erlenmeyer flask containing 50mL wort according to the inoculum amount of 10%, and cultured at 16° C. for 36 hours.

[0108] (2) Beer fermentation

[0109] Fermentation experiment: The secondary seed liquid was put into a 250mL Erlenmeyer flask filled with 150mL 10Brix nitrogen-deficient wort according to the inoculum amount of 10%, covered with a fermentation plug to kee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com