A fine-grain preparation method for copper parts of conical shells

A technology of fine crystallization and shell parts, which is applied in the field of metal plastic deformation and heat treatment of pure copper or copper alloy parts for fine crystallization and deformation. High requirements, serious cracking tendency of components, etc., to achieve the effect of easy industrial production, good product quality, and improved material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

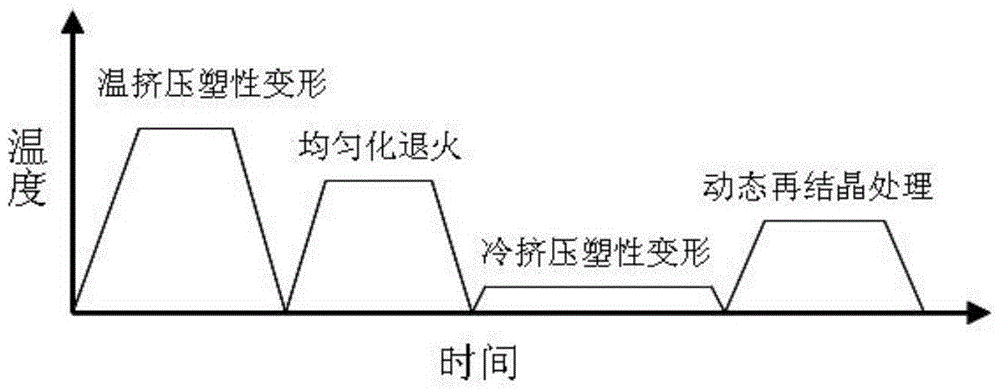

Method used

Image

Examples

Embodiment 1

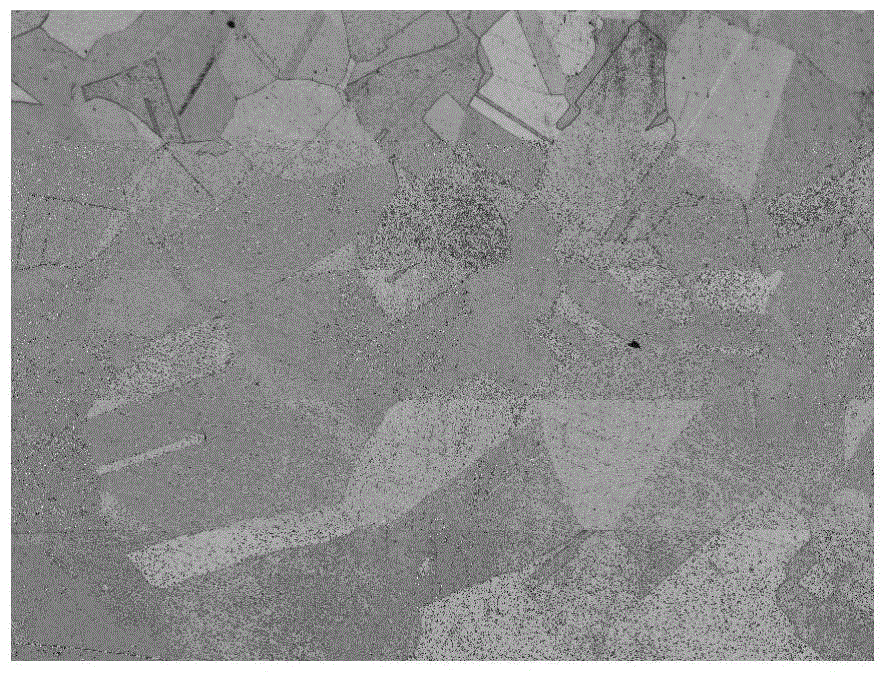

[0032] (1) Preparation of raw materials: The size of the large end of the conical shell is φ420mm, the height is 200mm, the depth of the inner cone is 192mm, and the maximum wall thickness is 6mm. According to the structural characteristics of the designed formed part, the rolled T2 copper rod of φ120mm is selected as the raw material , cutting and turning the outer surface to make a billet with a diameter of 118mm and a length of 80mm; the impurity element content of the T2 red copper rod is shown in Table 1, and the microstructure is as follows figure 2 shown.

[0033] Table 1 Content of impurity elements in T2 copper rods

[0034]

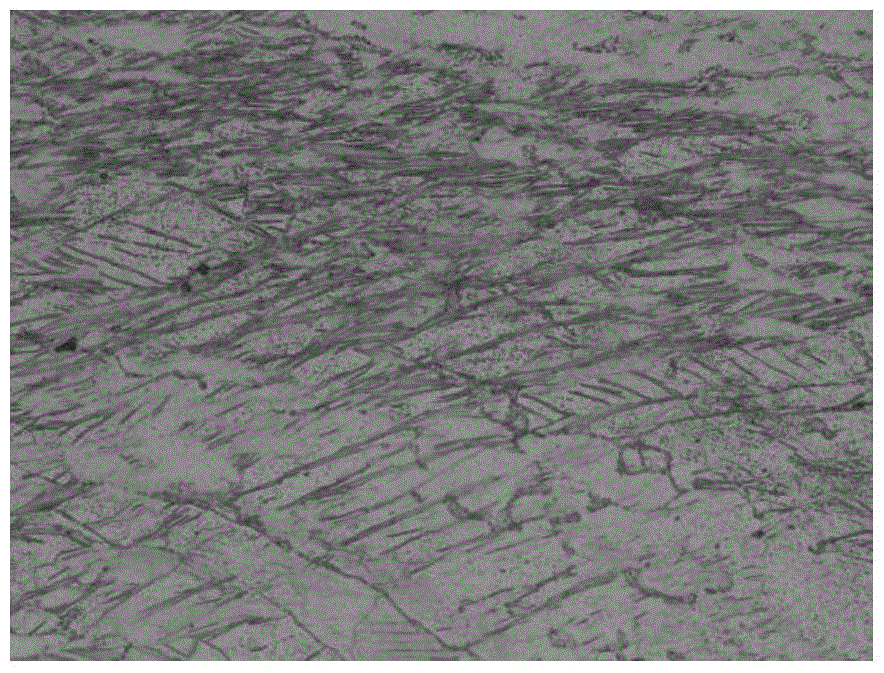

[0035] (2) Warm extrusion plastic deformation: put the blank obtained in step (1) into H 2 Heat treatment in atmosphere protection furnace (nitrogen purity 99.9%, humidity less than 0.05%), holding temperature 525±5℃, holding time 1.5h; mold tooling system holding temperature 550±5°C, holding time 2h; The final blank is put into the cavity o...

Embodiment 2

[0042] A kind of preparation method of conical shell copper parts adopts following steps (other steps and parameters are with embodiment 1):

[0043] (1) Preparation of raw materials: select the blank, cut the corresponding copper rod length, and cut the blank into a copper rod, the diameter of the copper rod is φ80mm; the copper material is pure copper, bronze, brass or cupronickel;

[0044] (2) Warm extrusion plastic deformation: put the billet obtained in step (1) into an atmosphere protection furnace for heat treatment, the holding temperature is 400°C, and the holding time is 2h. 4h; then put the heat-preserved and heated billet into the extrusion die cavity of the mold tooling system, and under the action of three-dimensional compressive stress and deformation rate, large plastic deformation forms a conical shell copper part. During the forming process, the surface of the billet and a layer of lubricant coated on the inner surface of the mold cavity; the lubricant is bar...

Embodiment 3

[0050] A kind of preparation method of conical shell copper parts adopts following steps (other steps and parameters are with embodiment 1):

[0051] (1) Preparation of raw materials: select the blank, cut the corresponding length of the copper rod, and cut the blank into a copper rod, the diameter of the copper rod is φ170mm; the copper material is pure copper, bronze, brass or cupronickel;

[0052] (2) Warm extrusion plastic deformation: put the blank obtained in step (1) into an atmosphere protection furnace for heat treatment, the holding temperature is 600°C, and the holding time is 1h. 2h; then put the thermally-heated billet into the extrusion die cavity of the mold tooling system, under the action of three-dimensional compressive stress and deformation rate, large plastic deformation forms a conical shell copper part, and the surface of the billet during the forming process and a layer of lubricant coated on the inner surface of the mold cavity; the lubricant is oil-ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com