A method of atomic layer deposition of al/ti thin films using titanium amino as titanium source

A technology of atomic layer deposition and amino titanium, which is applied in the direction of coating, metal material coating process, gaseous chemical plating, etc., can solve problems such as water absorption and affecting film performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

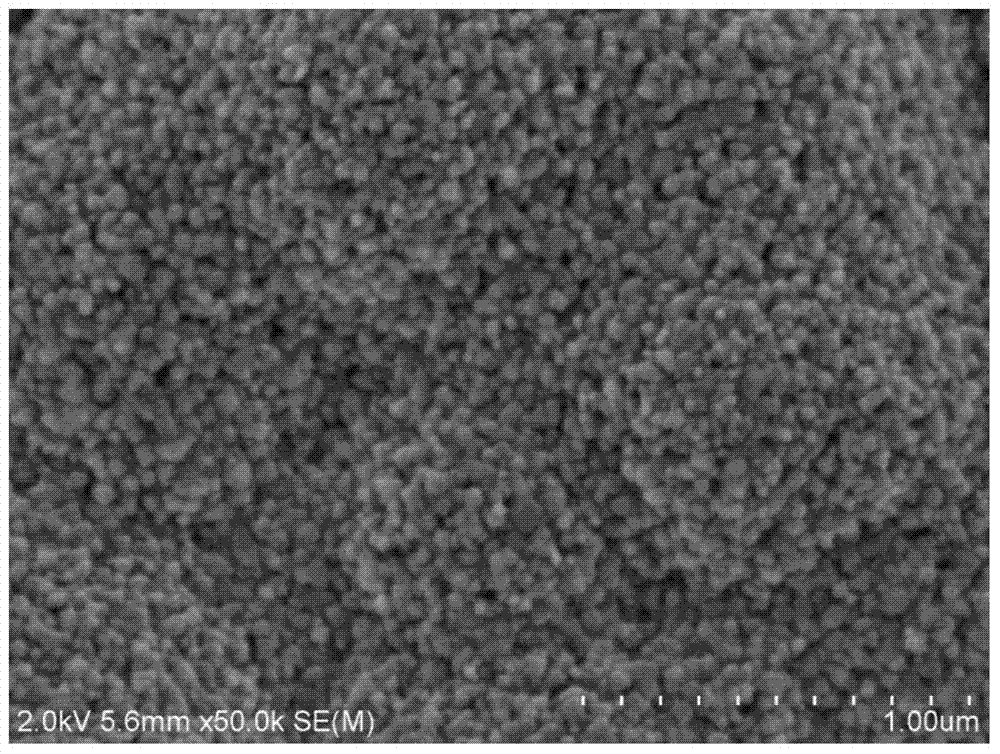

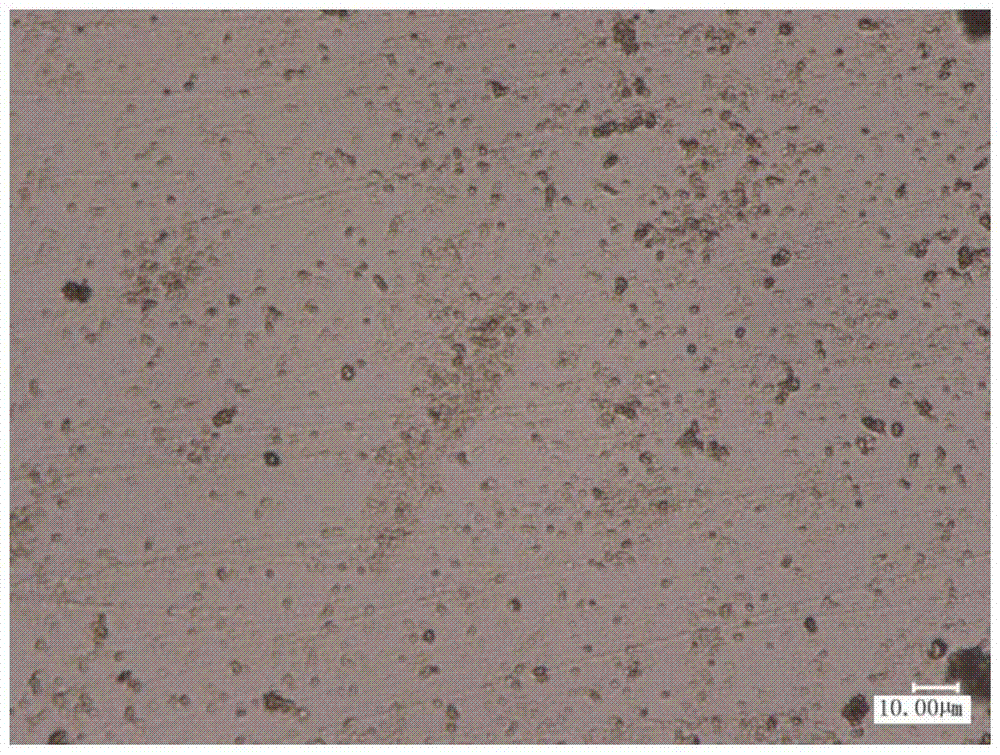

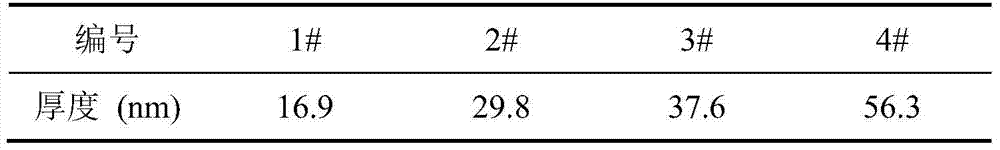

Image

Examples

Embodiment 1

[0034] Embodiment one: a kind of Al / Ti thin film atomic layer deposition method using amino titanium as titanium source, comprises the following steps:

[0035] (1) Carry out pretreatment to the substrate wafer of deposition thin film: select the substrate of resistivity 0.01Ωcm, adopt 98%H 2 SO 4 and 30%H 2 o 2 The mixed solution is cleaned, the volume ratio of the two is 7.0:2.0, and then rinsed with ultrapure water, N 2 Blow-dry, cycle cleaning times is 3 times;

[0036] (2) Accurately weigh trimethylamine alane as a deposition aluminum source in a glove box, Ti[N(CH 3 ) 2 ] 4 As the deposition titanium source, the molar ratio of the two is 2.0:0.5. The deposition system is purged with nitrogen for 1 hour, and the nitrogen flow rate is 140mL / min to drive out all the air and moisture in the system;

[0037] (3) Trimethylamine alane and Ti[N(CH 3 ) 2 ] 4And the cleaned substrate in step (1) is put into the thin film deposition system under the protection of nitrogen...

Embodiment 2

[0038] Embodiment two: a kind of Al / Ti thin film atomic layer deposition method using amino titanium as titanium source, comprises the following steps:

[0039] (1) Carry out pretreatment to the substrate wafer of deposition thin film: select the substrate of resistivity 0.02Ωcm, adopt 98%H 2 SO 4 and 30%H 2 o 2 The mixed solution is cleaned, the volume ratio of the two is 7.0:3.0, and then rinsed with ultrapure water, N 2 Blow dry, cycle cleaning times is 5 times;

[0040] (2) Accurately weigh dimethylethylamine alane in the glove box as the deposition aluminum source, Ti[N(CH 2 CH 3 ) 2 ] 4 As the deposition titanium source, the molar ratio of the two is 2.0:1.0. The deposition system is purged with nitrogen for 2 hours, and the nitrogen flow rate is 145mL / min to drive out all the air and moisture in the system;

[0041] (3) Dimethylethylaminealane and Ti[N(CH 2 CH 3 ) 2 ] 4 And the cleaned substrate in step (1) is placed in the thin film deposition system under ...

Embodiment 3

[0042] Embodiment three: a kind of Al / Ti thin film atomic layer deposition method using amino titanium as titanium source, comprises the following steps:

[0043] (1) Carry out pretreatment to the substrate wafer of deposition thin film: select the substrate with resistivity 0.03Ωcm, adopt 98%H 2 SO 4 and 30%H 2 o 2 The mixed solution is cleaned, the volume ratio of the two is 7.0:4.0, and then rinsed with ultrapure water, N 2 Blow dry, cycle cleaning times is 6 times;

[0044] (2) Accurately weigh diethylaluminum hydride as the source of deposited aluminum in the glove box, Ti{N[CH(CH 3 ) 2 ] 2} 4 As the deposition titanium source, the molar ratio of the two is 2.0:1.5, and the deposition system is purged with nitrogen for 2 hours, and the nitrogen flow rate is 145mL / min to drive out all the air and moisture in the system;

[0045] (3) Diethylaluminum hydride and Ti{N[CH(CH 3 ) 2 ] 2} 4 And the cleaned substrate in step (1) is put into the thin film deposition sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com