Preparation method and application of nanogold composite material immunosensor

A technology of immune sensor and composite material, which is applied in the field of preparation of nano-gold composite material immune sensor, can solve the problems of low efficiency of nano-gold, and achieve the effects of good water solubility, improved utilization rate and good activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

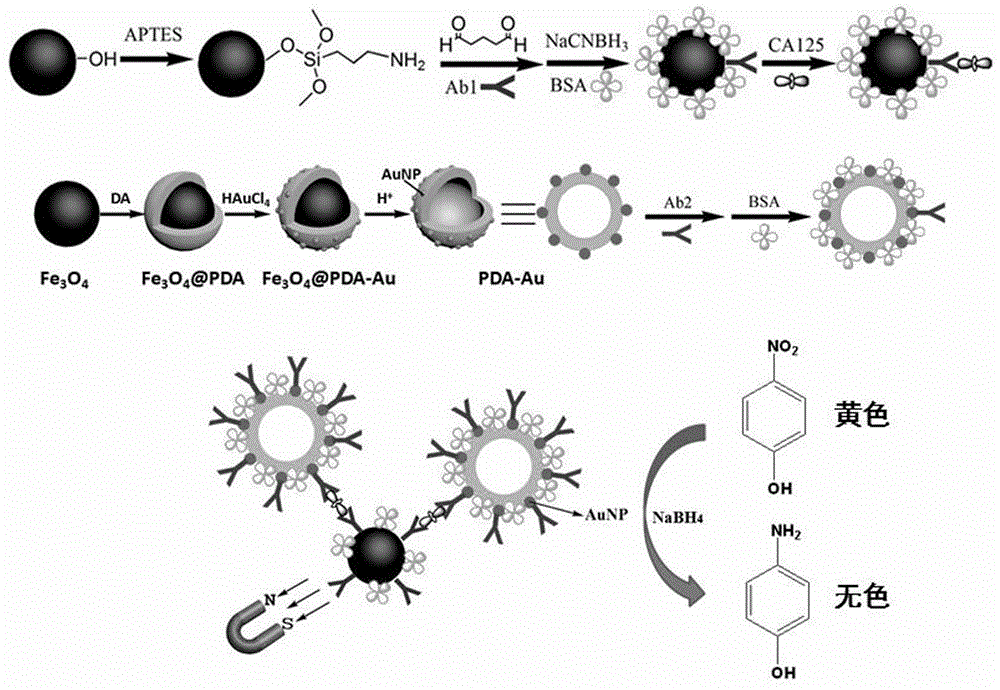

Method used

Image

Examples

Embodiment 1

[0038] (1) Preparation of aminated Fe 3 o 4 Nano magnetic beads

[0039] 0.325g anhydrous FeCl 3 and 0.2 g of sodium citrate were dispersed in 20 mL of ethylene glycol, stirred for 1 h to dissolve the solid completely, then 1.2 g of sodium acetate was added and stirred for 30 min, the mixture was added to a hydrothermal reaction kettle with a volume of 50 mL, and placed in an oven, Keep at 200°C for 12 hours, and when the reactor is cooled to room temperature, take it out, and the black precipitate at the bottom of the reactor is Fe 3 o 4 Nano-magnetic beads, using a magnet for magnetic separation, the obtained Fe 3 o 4 Washed three times with water and ethanol respectively, dried in vacuum at 50°C for 12 hours, and obtained 4 mg Fe 3 o 4 Disperse in 10 mL of water, add 20 μL of 3-aminopropyltriethoxysilane, and stir at room temperature for 6 hours to obtain aminated Fe 3 o 4 nano magnetic beads;

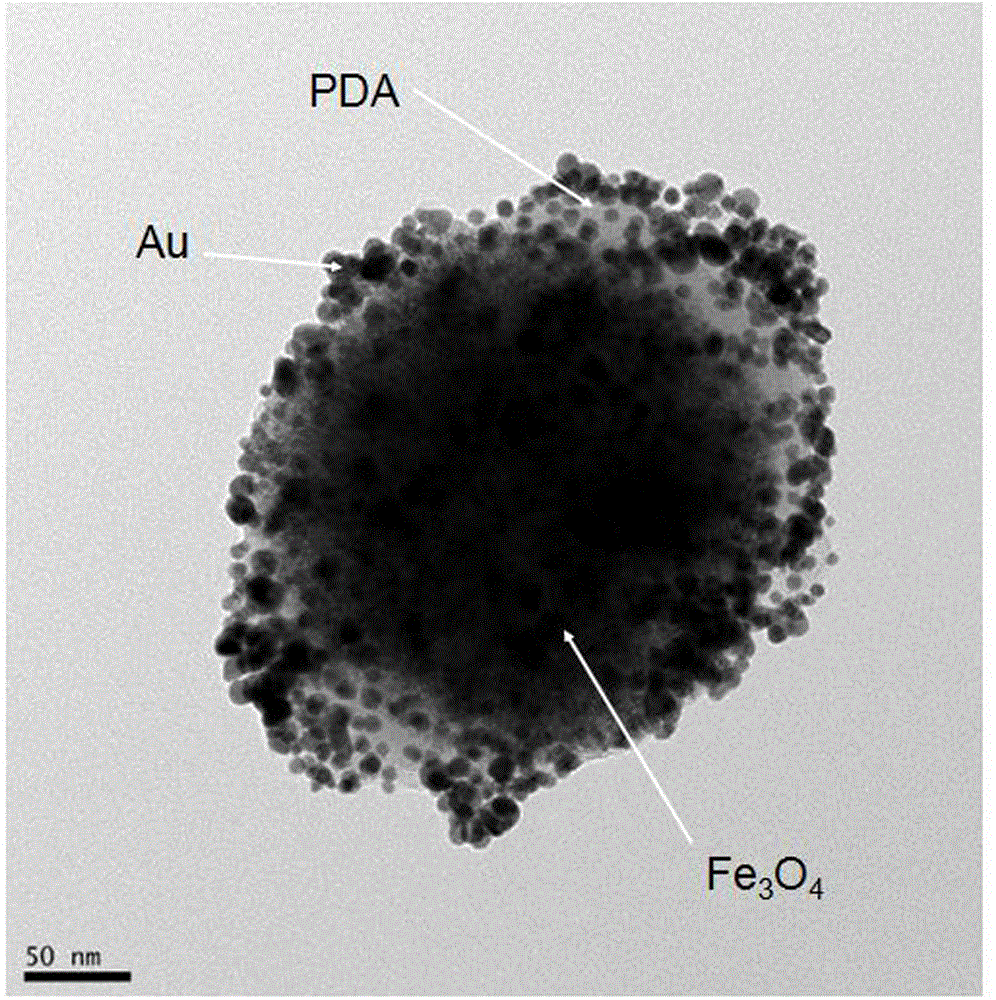

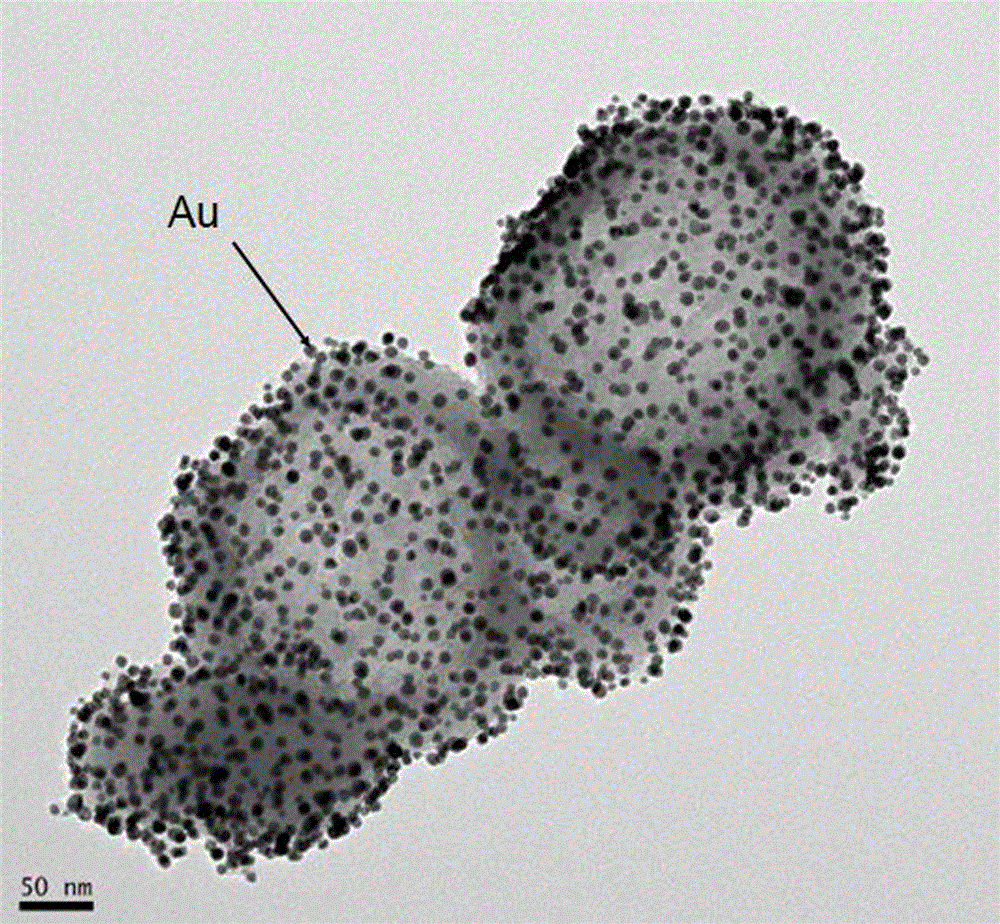

[0040] (2) Preparation of hollow polydopamine-gold nanomaterials (PDA...

Embodiment 2

[0051] (1) Preparation of aminated Fe 3 o 4 Nano magnetic beads

[0052] 0.325g anhydrous FeCl 3 Disperse with 0.2g sodium citrate in 20mL ethylene glycol, stir for 1h to completely dissolve the solid; then add 1.2g sodium acetate and stir for 30min. The mixture was added into a hydrothermal reaction kettle with a volume of 50 mL, put into an oven, and kept at 200 °C for 12 h, and was taken out when the reaction kettle was cooled to room temperature. The black precipitate at the bottom of the reaction kettle is Fe 3 o 4 Nano-magnetic beads, using a magnet for magnetic separation, the obtained Fe 3 o 4 Wash with water and ethanol three times respectively, and dry in vacuum at 50°C for 12h. Take 4mg Fe 3 o 4 Disperse in 10 mL of water, add 20 μL of 3-aminopropyltriethoxysilane, stir at room temperature for 6 h, and the obtained aminated Fe 3 o 4 nano magnetic beads;

[0053] (2) Preparation of hollow polydopamine-gold nanomaterials (PDA-Au)

[0054] Weigh 40 mg Fe ...

Embodiment 3

[0064] (1) Preparation of aminated Fe 3 o 4 Nano magnetic beads

[0065] 0.325g anhydrous FeCl 3 and 0.2 g of sodium citrate were dispersed in 20 mL of ethylene glycol, stirred for 1 h to completely dissolve the solid, then added 1.2 g of sodium acetate and stirred for 30 min, and the mixture was added to a hydrothermal reaction kettle with a volume of 50 mL, and placed in an oven , Keep at 200°C for 12h, and take it out when the reactor is cooled to room temperature. The black precipitate at the bottom of the reaction kettle is Fe 3 o 4 Nano-magnetic beads, using a magnet for magnetic separation, the obtained Fe 3 o 4 Wash with water and ethanol three times respectively, and dry in vacuum at 50°C for 12h. Take 4mg Fe 3 o 4 Disperse in 10mL water, add 20μL 3-aminopropyltriethoxysilane, stir at room temperature for 6h, and the obtained aminated Fe 3 o 4 nano magnetic beads;

[0066] (2) Preparation of hollow polydopamine-gold nanomaterials (PDA-Au)

[0067] Weigh 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com