A kind of flexible thin film solar cell

A technology of solar cells and flexible films, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of high equipment requirements, high price, low battery efficiency, etc., and achieve excellent radiation resistance, simple preparation method, and electron transfer rate. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

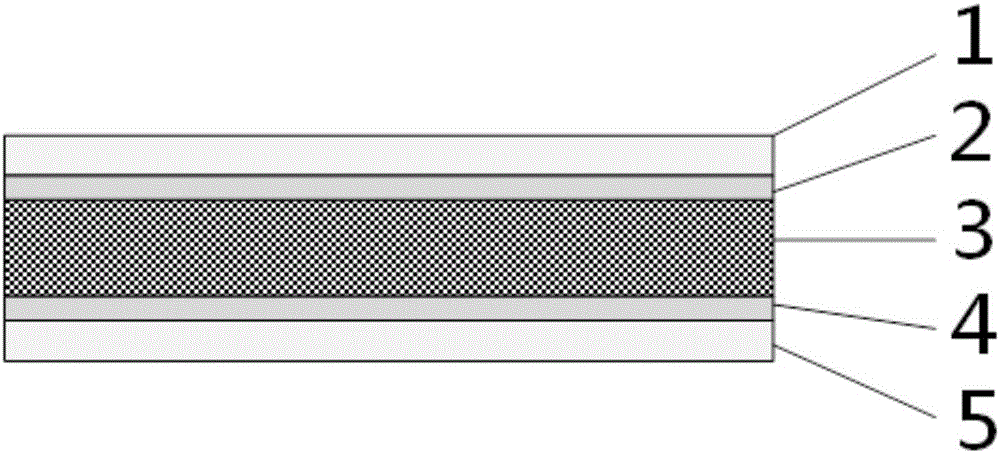

[0028] The structure of the flexible thin film solar cell of this embodiment is as follows figure 1 Shown:

[0029] Included from top to bottom:

[0030] Upper substrate 1, graphene positive electrode 2, photovoltaic material layer 3, graphene negative electrode 4 and lower substrate 5;

[0031] In this example:

[0032] The upper substrate 1 and the lower substrate 5 are PI films (also other transparent films) with a thickness of 100 microns;

[0033] The photovoltaic material layer is made of CdTe nanoparticles with a thickness of 200-400nm;

[0034] The graphene positive electrode is p-type doped graphene with a thickness of 0.5nm. The specific doping method is: place the graphene electrode in AuCl with a concentration of 0.01-0.1mg / mL 3 10-30 minutes in solution.

[0035] The graphene negative electrode is p-type doped graphene with a thickness of 0.5 nm.

[0036] The specific doping method is: place the graphene electrode in 2-(2-methoxyphenyl)-1,3-dimethyl-2,3-dihy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com