Lithium titanate/carbon composite material and method for preparing material

A carbon composite material, lithium titanate technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of high preparation cost, difficult to scale production, poor electrical performance, etc., and achieve good electrical conductivity and good electrochemical performance. , the effect of high rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

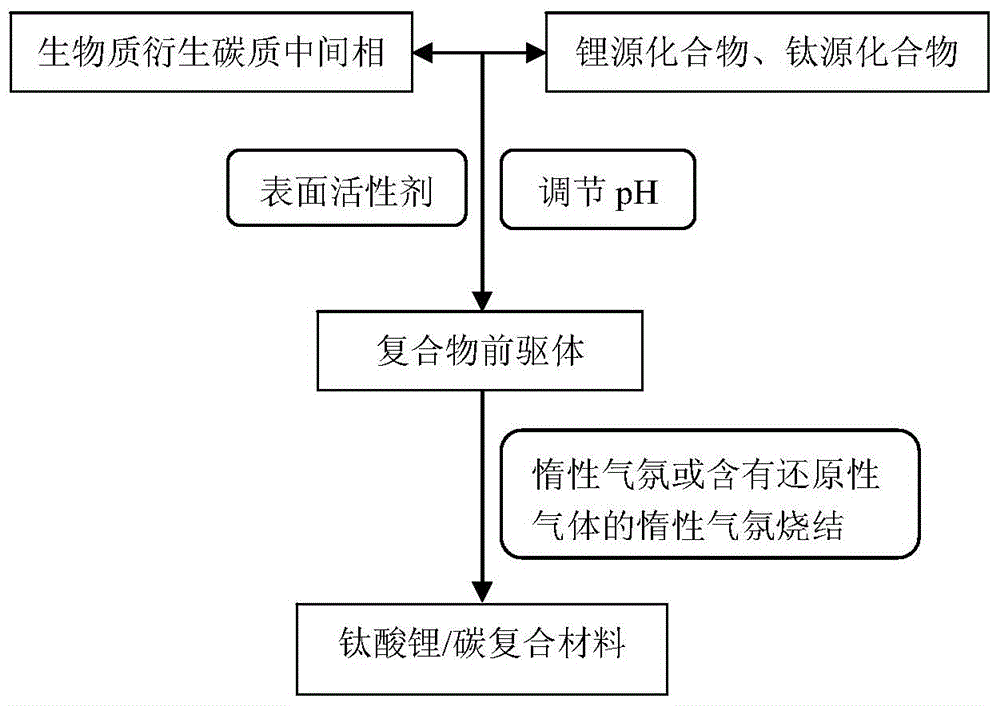

Method used

Image

Examples

Embodiment 1

[0053] The method for preparing lithium titanate / carbon composite material in the present embodiment is as follows:

[0054] 1) Dissolving 0.01 g of biomass-derived carbonaceous mesophase in 100 mL of ethanol to obtain mesophase solution A with a concentration of 1 g / L;

[0055] 2) Add 10 g of lithium titanate and 0.01 g of sodium dodecyl sulfate to the mesophase solution A under stirring conditions, and obtain a lithium titanate / carbon composite precursor through centrifugal drying and ball milling;

[0056] 3) heat-treating the lithium titanate / carbon composite precursor in an argon atmosphere at 650° C. for 3 h, and cooling to obtain the final product lithium titanate / carbon composite material.

[0057] The biomass-derived carbonaceous mesophase in this example is the biomass-derived carbonaceous mesophase obtained in Example 1 in the publication number CN 1421477A.

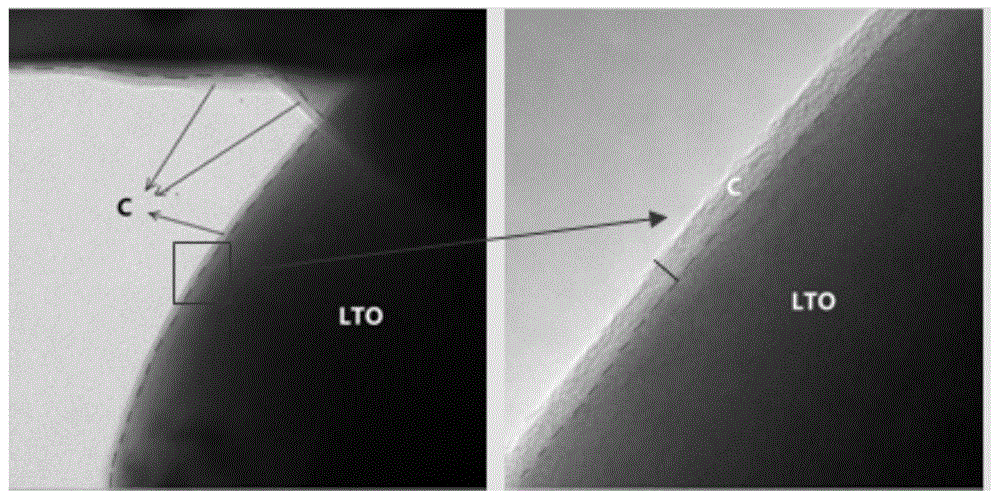

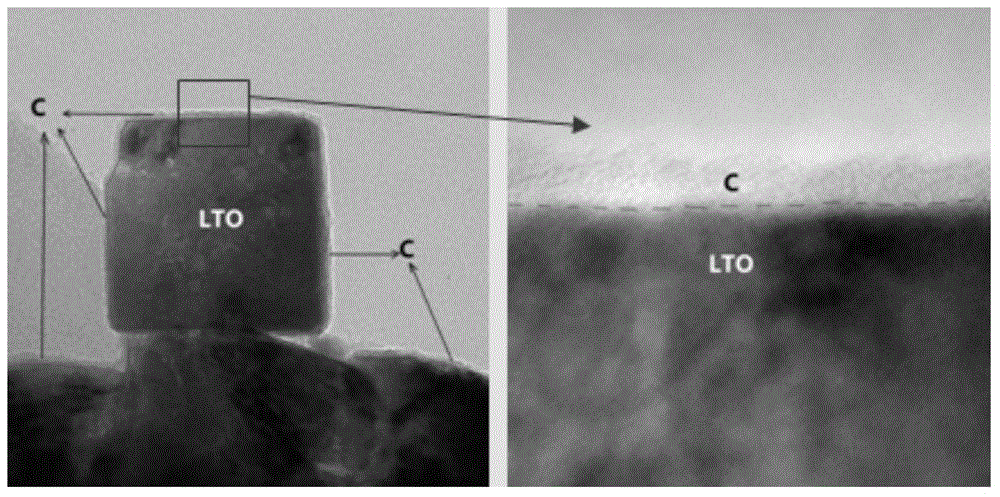

[0058] The TEM photo of the prepared lithium titanate / carbon composite is shown in figure 2 . From the ...

Embodiment 2

[0060] The method for preparing lithium titanate / carbon composite material in the present embodiment is as follows:

[0061] 1) Dissolving 1 g of biomass-derived carbonaceous mesophase in 100 mL of ethanol to obtain mesophase solution A with a concentration of 10 g / L;

[0062] 2) Under the condition of stirring, the molar ratio between Li:Ti is 0.6, take by weighing 2.50g of titanium dioxide and 0.69g of lithium carbonate, and take by weighing 0.05g of sodium dodecylbenzenesulfonate and add in the mesophase solution A , after centrifugal drying and ball milling, the lithium titanate / carbon composite precursor was obtained;

[0063] 3) The lithium titanate / carbon composite precursor was heat-treated at 1000° C. for 14 hours in argon containing 10% hydrogen, and cooled to obtain the final lithium titanate / carbon composite material.

[0064] The biomass-derived carbonaceous mesophase in this example is the biomass-derived carbonaceous mesophase obtained in Example 2 of the publi...

Embodiment 3

[0067] The method for preparing lithium titanate / carbon composite material in the present embodiment is as follows:

[0068] 1) Dissolving 0.1 g of biomass-derived carbonaceous mesophase in 100 mL of ethanol to obtain mesophase solution A with a concentration of 1 g / L;

[0069] 2) Under stirring conditions, according to the molar ratio of Li:Ti being 0.82, weigh 30g of tetrabutyl titanate titanium and 7.37g of lithium acetate and 0.03g of sodium dodecyl sulfate into the intermediate phase solution A, and use acetic acid to Adjust the pH value to 6.5 and stir until a gel is formed; the gel is vacuum dried and ball milled to obtain a lithium titanate / carbon composite precursor;

[0070] 3) heat-treating the lithium titanate / carbon composite precursor at 850° C. for 5 h in a nitrogen-containing atmosphere, and cooling to obtain the final lithium titanate / carbon composite material.

[0071] The biomass-derived carbonaceous mesophase in this example is the biomass-derived carbonac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com