Method for adsorbing uranium by using macroporous poly-N-isopropylacrylamide/chitosan semi-interpenetrating network temperature-sensitive hydrogel

A technology of isopropylacrylamide and semi-interpenetrating network, applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc. poor mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) Accurately weigh 0.5g of chitosan monomer and dissolve it in acetic acid with a mass fraction of 5%, add 15g of NIPAAm monomer and 0.5g of cross-linking agent MBA, and mix well.

[0024] 2) Add 0.6 mL of emulsifier stabilizer PVA and 0.8 mL of emulsifier Span-80 under stirring, and add 0.03 g of initiator APS and 60 μL of accelerator TEMED after stirring for 5-10 min.

[0025] 3) After stirring for 10-15 min and standing still for 24 h, take out the gel, wash off the pore-forming agent Span-80 and PVA with ethanol, then soak in distilled water for 48 h, change the water regularly to remove unreacted monomers, and residual triggers agent or catalyst, and finally the gel was cut into pieces and freeze-dried for later use.

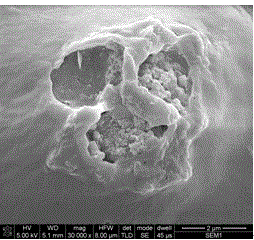

[0026] figure 1 It is the scanning electron microscope picture of the macroporous gel, the magnification is 5000 times, figure 2 The magnification is 25000 times. It can be seen from the figure that there is an obvious pore structure inside t...

Embodiment 2

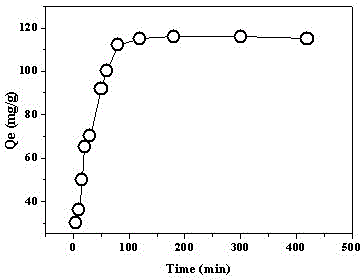

[0028] The hydrogel prepared in Example 1 was used to investigate the adsorption performance of uranium, and three 0.03g gels were accurately weighed, and the first one was used as a control sample. Add the second part to 70 μg / mL uranium standard solution, shake at 308.15K for an appropriate time, take 1 mL of supernatant at regular intervals, add 2 mL of buffer solution, 2 mL of arsenazo III, and dilute to 25 mL, measure the absorbance, analyze the concentration of uranium in the solution before and after adsorption, and calculate the amount of uranium adsorbed. Add the third part to 70 μg / mL uranium standard solution, shake at two temperature points of 293.15K and 323.15K for an appropriate time, take 1 mL of supernatant at regular intervals, add 2 mL of buffer solution, 2 mL of arsenazo III , set the volume to 25 mL, measure the absorbance, and calculate the adsorption amount of uranium.

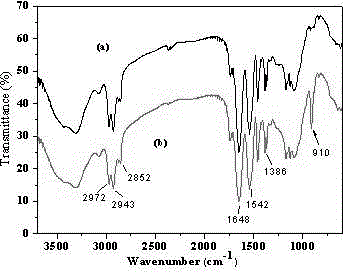

[0029] image 3 is the infrared spectrum of the macroporous gel that has not ads...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com