Preparation and application of Nd<3-x>CoxNbO7-zincosilicate molecular sieve composite porous nanometer catalytic material

A nano-catalytic material, silicon-zinc molecular sieve technology, applied in molecular sieve catalysts, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of increasing drug-resistant strains, expanding the scope of harm, and health hazards And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] (1) Preparation of silicon-zinc molecular sieves: in an alkaline state, the molar composition ratio of SiO 2 / ZnO=5 / 45 Add zinc oxide and citric acid complexing agent to the silicate solution. The role of the complexing agent is to maintain the stability of zinc in alkaline solution and colloid through the complexation of the complexing agent and zinc ions, inhibit the formation of zinc oxide or hydroxide, and increase the zinc content of the molecular sieve framework and molecular sieve crystallinity. Then, after hydroheating for 5 hours, filter and dry, and then crush and screen to obtain the desired silicon-zinc molecular sieve. This zeolite has high crystallinity, and it is confirmed by XRD and FTIR that zinc enters the framework of the molecular sieve.

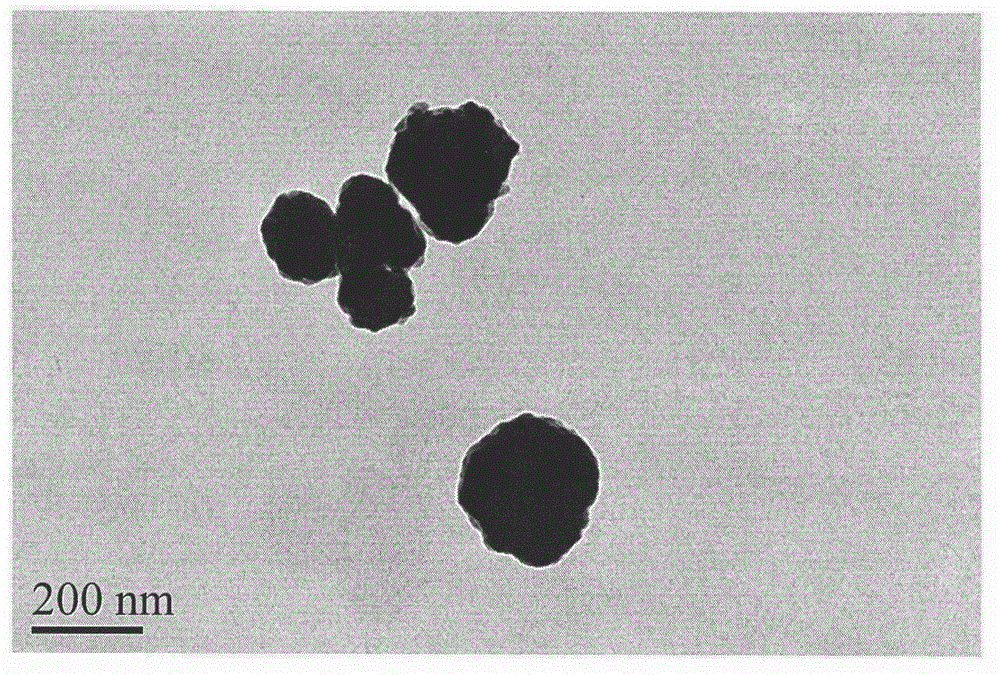

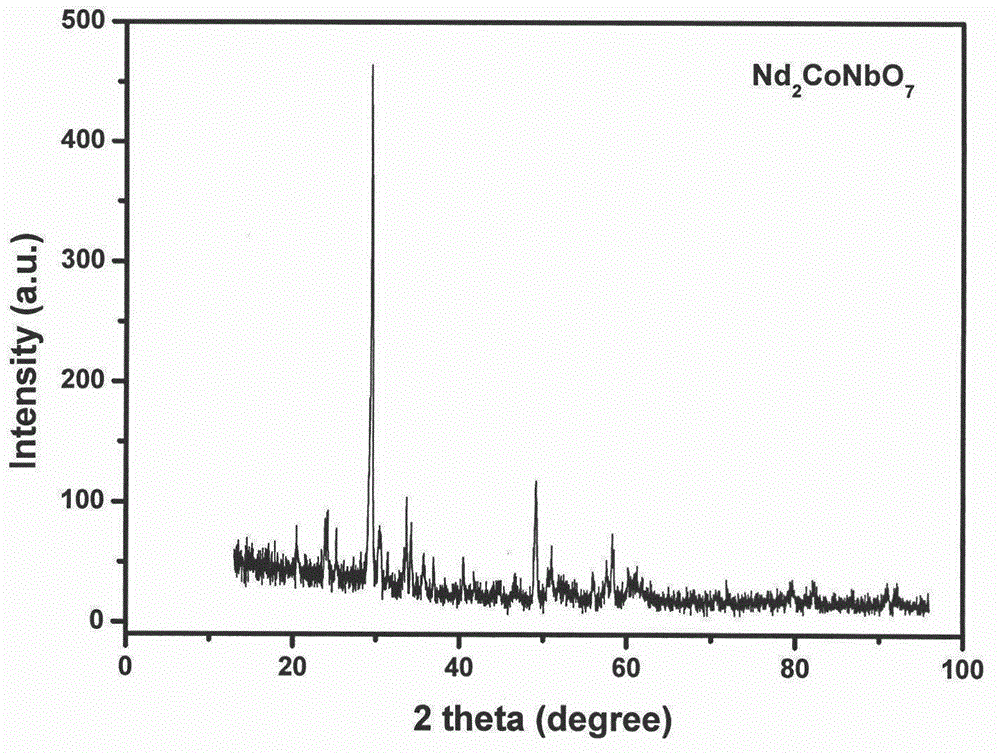

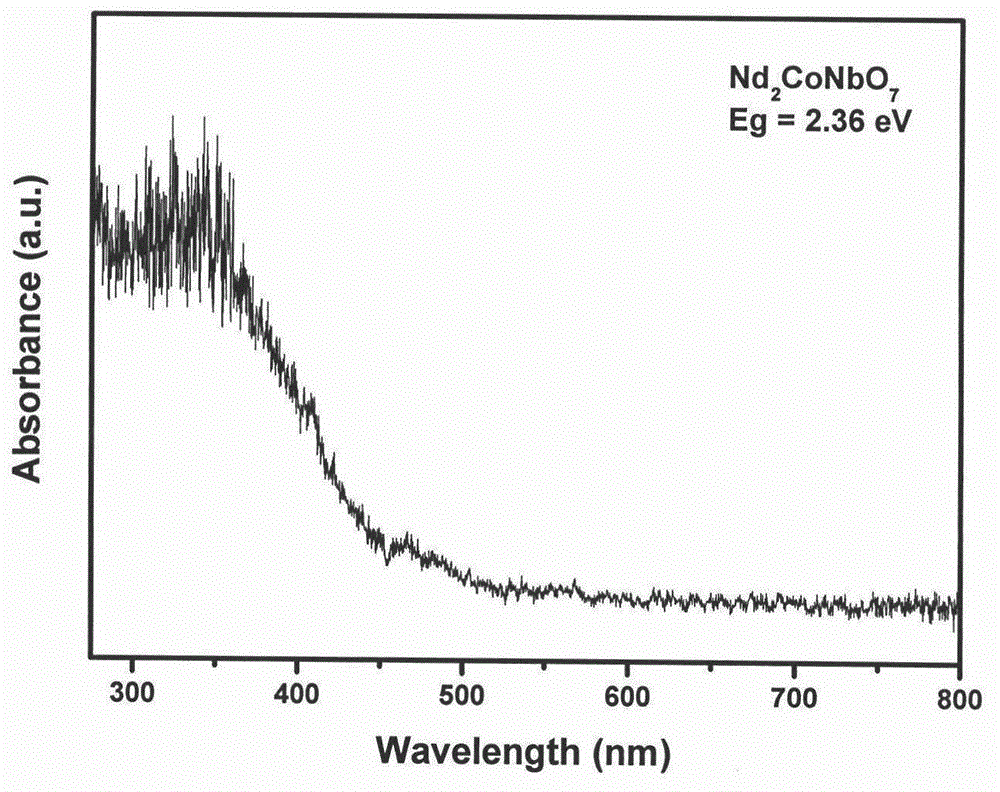

[0040] (2) Composite Nd by dipping and baking method 3-x co x NbO 7 (0.5≤x≤1)-silicon-zinc molecular sieve process route: weigh a certain amount of Nd 3-x co x NbO 7 (0.5≤x≤1) The catalyst was dissolved in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com