Method for preparing biomass based carbon quantum dots

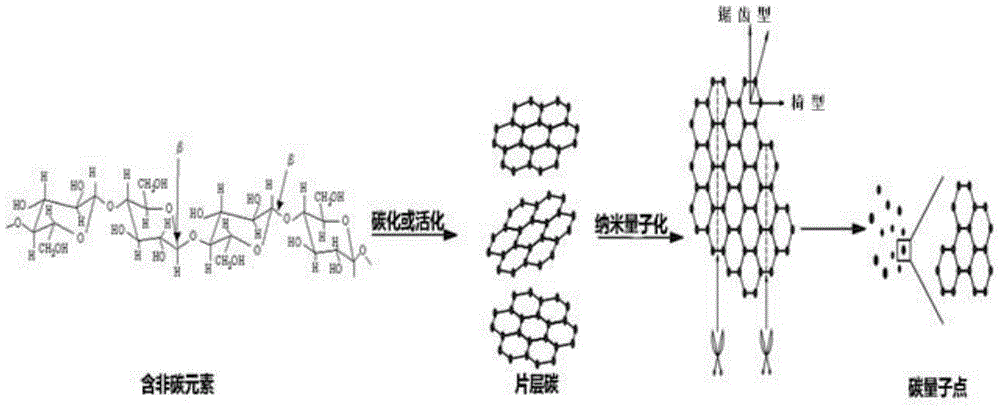

A carbon quantum and biomass-based technology, applied in chemical instruments and methods, nanotechnology, nano-optics, etc., can solve the problems of limited performance of carbon quantum dots, high equipment requirements, complicated steps, etc., and achieve good green fluorescence effect, Simple preparation process and wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

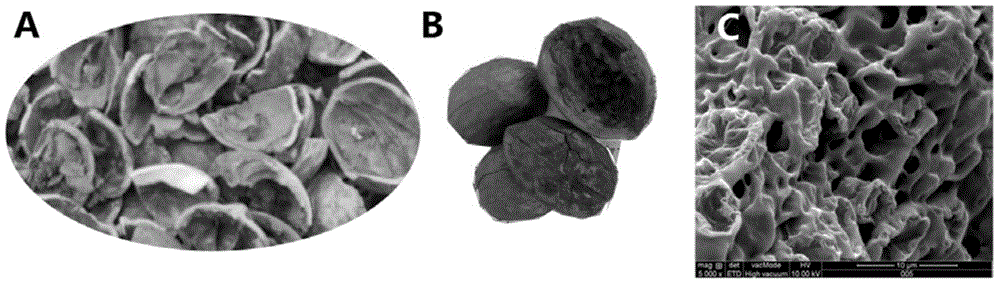

[0033] Pre-oxidize walnut shells soaked with a catalyst (a mixture of urea and phosphoric acid at a molar ratio of 2:1) in air at 100°C, 150°C, and 250°C for 30 minutes, then place them in a tube-type high-temperature electric furnace, and blow nitrogen Protection, 350°C, 600°C, 800°C for 20 minutes, take it out for later use.

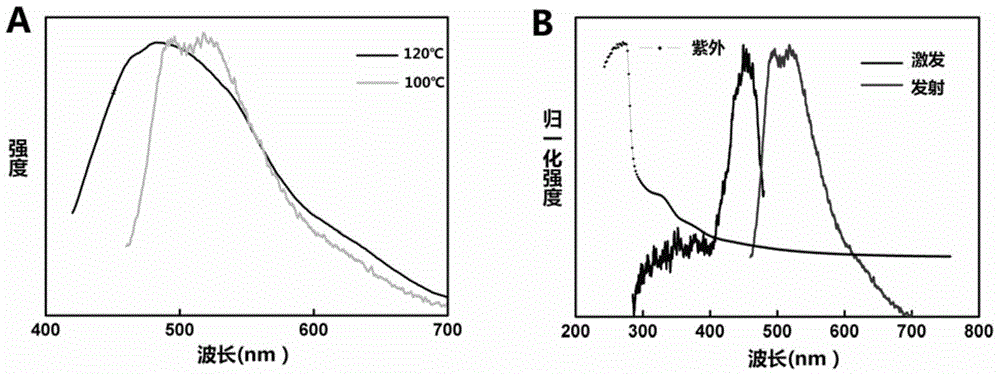

[0034] Weigh 0.3g of carbonized raw material, disperse in a mixture of 20ml of nitric acid and 60ml of concentrated sulfuric acid, and ultrasonicate at room temperature for 2h. Reflux at 80°C for 24 hours, and the concentrated acid mixture quantizes the sheet-layer carbon structure into carbon quantum dots. After the reaction, cool to room temperature, dilute 10 times, adjust the pH of the solution to 7 with sodium carbonate, filter with a 0.22 μm microporous filter head, and dialyze with a 2000 Da dialysis bag for 3 days to remove salt and other components and impurities to obtain yellow fluorescent carbon quantum The aqueous solution of the point, t...

Embodiment 2

[0037] Pre-oxidize walnut shells soaked with a catalyst (a mixture of urea and phosphoric acid at a molar ratio of 2:1) in air at 100°C, 150°C, and 250°C for 30 minutes, then place them in a tube-type high-temperature electric furnace, and blow nitrogen Protection, 350°C, 600°C, 800°C for 20 minutes, take it out for later use.

[0038] Weigh 0.3g of carbonized raw material, disperse in a mixture of 20ml of nitric acid and 60ml of concentrated sulfuric acid, and ultrasonicate at room temperature for 2h. Reflux at 100°C for 24 hours, and the concentrated acid mixture quantizes the sheet-layer carbon structure into carbon quantum dots. After the reaction, cool to room temperature, dilute 10 times, adjust the pH of the solution to 7 with sodium carbonate, filter with a 0.22 μm microporous filter head, and dialyze with a 2000 Da dialysis bag for 3 days to remove salt and other impurities to obtain green fluorescent carbon quantum The aqueous solution of the point, the product size...

Embodiment 3

[0042] Pre-oxidize walnut shells soaked with a catalyst (a mixture of urea and phosphoric acid at a molar ratio of 2:1) in air at 100°C, 150°C, and 250°C for 30 minutes, then place them in a tube-type high-temperature electric furnace, and blow nitrogen Protection, 350°C, 600°C, 800°C for 20 minutes, take it out for later use.

[0043] Weigh 0.3g of carbonized raw material, disperse in a mixture of 10ml of nitric acid and 30ml of concentrated sulfuric acid, and ultrasonicate at room temperature for 2h. Reflux at 80°C for 24 hours, and the concentrated acid mixture quantizes the sheet-layer carbon structure into carbon quantum dots. After the reaction, cool to room temperature, dilute 10 times, adjust the pH of the solution to 1 with sodium carbonate, filter with a 0.22 μm microporous filter head, and dialyze with a 2000 Da dialysis bag for 3 days to remove salt and other components and impurities to obtain yellow fluorescent carbon quantum The aqueous solution of the point, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com