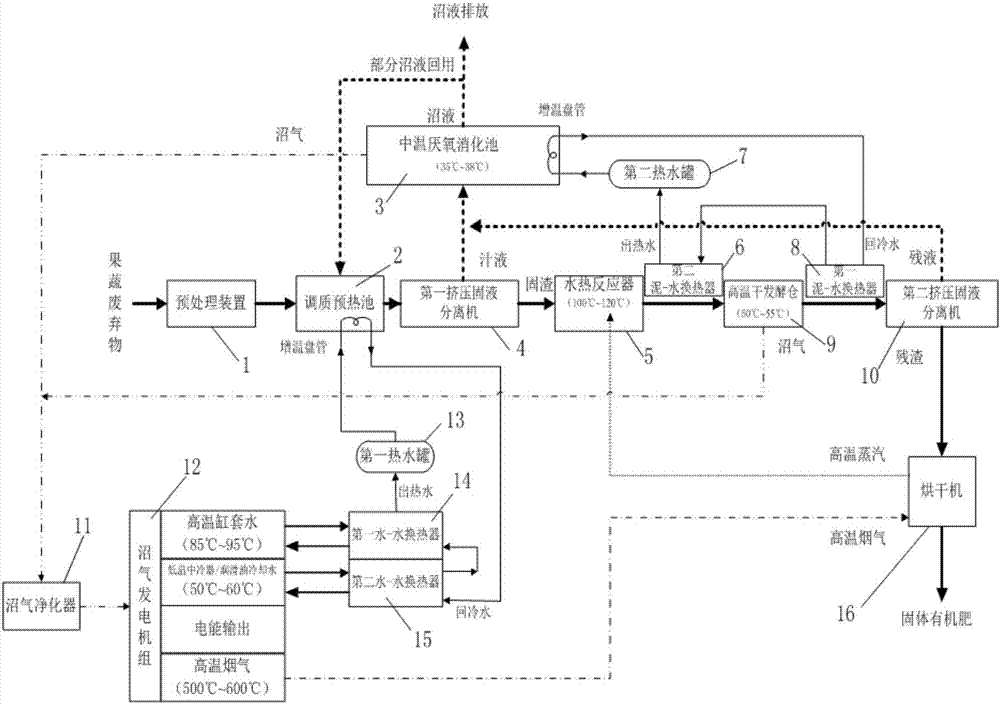

System and method for coupled utilization of fruit and vegetable waste anaerobic fermentation and waste heat of biogas generator

A technology of generator waste heat and anaerobic fermentation, which is applied in the direction of bioreactor/fermenter combination, fuel system, engine components, etc., can solve the problems of lack of resource utilization of solid residue, reduction of raw material methane yield, consumption of organic carbon, etc. , to achieve the effect of improving the comprehensive energy and resource utilization efficiency of fruit and vegetable waste, improving the gas production rate of raw materials, and improving the treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Collect 100 tons of vegetable waste from a vegetable planting professional cooperative. Since the vegetable waste is collected at the source, there is basically no impurity, so the pretreatment device 1 is only a crusher; the solid content of the vegetable waste is 12%, and the vegetable waste is crushed to a particle size ≤ 50mm , put it into conditioning and tempering preheating pool 2 after crushing, add 50 tons of biogas slurry from mesophilic anaerobic digester 3, adjust the total solid concentration of 2 materials in the conditioning and tempering preheating pool to be 8%, and pass through the first hot water tank 13 hot water to the temperature-increasing coil in the tempering preheating pool 2, so that the temperature of the material in the tempering preheating pool 2 is 40°C; pump the fruit and vegetable waste after conditioning and tempering into the first extrusion solid-liquid separation Machine 4 carries out solid-liquid separation to obtain 124.5 tons of ju...

Embodiment 2

[0052] Collect 130 tons of fruit and vegetable waste from a bazaar, sort and remove 10 tons of soft plastic, foam, rope and other sundries through the pretreatment device, and the solid content of the remaining 120 tons of fruit and vegetable waste is 10%. Crushed to a particle size ≤ 50mm, put it into the tempering preheating tank after crushing, add 80 tons of biogas slurry from the mesophilic anaerobic digester 3, adjust the total solid concentration of the material in the conditioning and tempering preheating tank 2 to 6%, and The hot water from the first hot water tank 13 is sent to the temperature-increasing coil in the tempering and preheating pool 2, so that the temperature of the material in the tempering and preheating pool 2 is 35°C; Squeeze solid-liquid separator 4 to carry out solid-liquid separation to obtain 177.5 tons of juice and 22.5 tons of solid residue, the total solid content of solid residue is 40%, and the total chemical oxygen demand (COD) of juice is 1...

Embodiment 3

[0054]Collect 200 tons of fruit and vegetable waste from a fruit and vegetable logistics park, sort and remove 20 tons of soft plastic, foam, baskets, wood boards, quilts, ropes and other sundries through the pretreatment device 1, and the remaining 180 tons of fruit and vegetable waste are solid The content is 13%, the vegetable waste is crushed to a particle size ≤ 50mm, after crushing, it is put into the tempering preheating pool 2, and 201 tons of biogas slurry from the medium temperature anaerobic digester 3 is added to adjust the tempering preheating pool 2 The material total solid concentration is 7%, and through the hot water of the first hot water tank 13 to the temperature-increasing coil in the conditioning and tempering preheating pool 2, the temperature of the material in the conditioning and tempering preheating pool 2 is 37.5 ° C; The warmed fruit and vegetable waste is pumped into the first extrusion solid-liquid separator 4 for solid-liquid separation to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com