Bacillus subtilis and soybean meal fermentation pre-treatment process

A technology of Bacillus subtilis and fermented soybean meal, which is applied to bacteria, microorganisms, animal feed, etc., can solve the problem of not being able to completely degrade anti-nutritional factors, and achieve the advantages of being beneficial to animal absorption and utilization, promoting animal growth, and increasing acid-soluble protein content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0092] Embodiment 1: strain preparation

[0093] 1. Separate and take 1g of the plant root soil of Haloxylon tree (Gurbantunggut Desert, Xinjiang), dissolve it in 10ml of sterile water, bathe in water at 80°C for 15min, and then dilute it with sterile water 10 times, and take 4 dilution gradients (10 -3 、10 -4 、10 -5 、10 -6 ) bacteria suspension on LB plates, at least 5 plates for each dilution, cultured at 37°C for about 24 hours to obtain a single colony.

[0094] 2. Pick a single colony from the primary screening and place it on a milk plate (5wt% skimmed milk, 0.5wt% yeast extract, 1wt% tryptone, 1wt% glucose, 1.5wt% agar), culture at 37°C for 16 hours, and select a large hydrolysis circle. The strains were examined under a microscope and purified by streak separation to obtain the strains for primary screening.

[0095] 3. The re-screening is carried out with 4 indicators of acid-soluble protein increase, trypsin inhibitor degradation, oligosaccharide (stachyose, raf...

Embodiment 2

[0099] Example 2: Characteristics of strains

[0100] 1. Morphological characteristics:

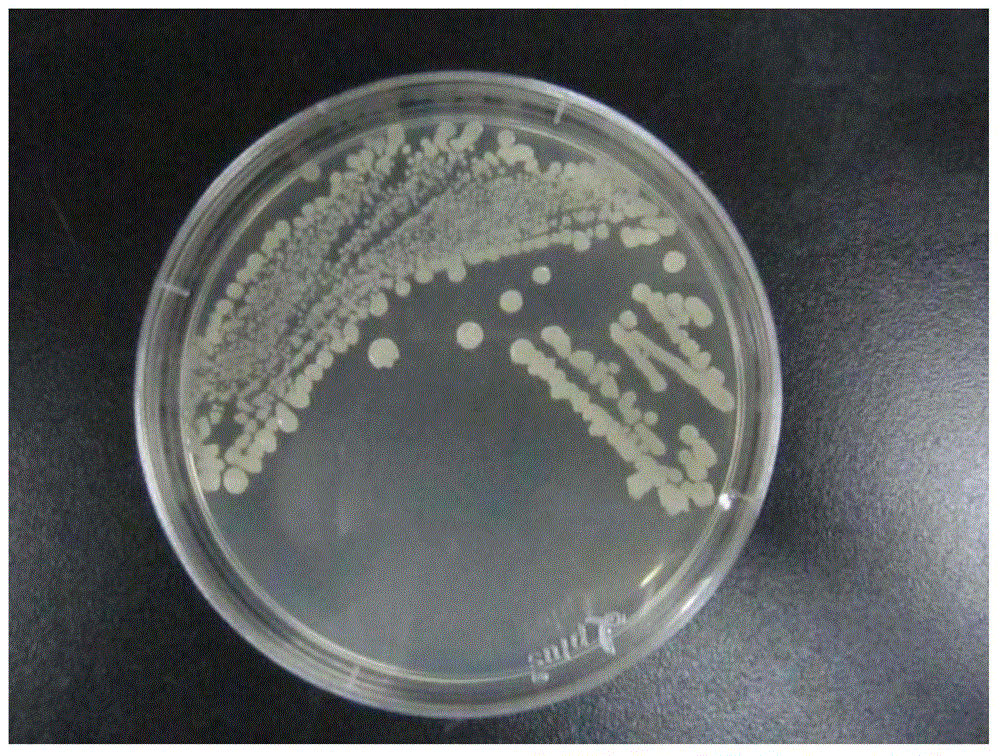

[0101] The strain WBRD00470-B3 was streak cultured on LB medium at 37°C for 24 hours, and the growth morphology of the strain was observed. The results were as follows: figure 2 shown.

[0102] according to figure 2 As a result, the colony is round, moist on the surface, rough and opaque, with irregular edges, white or yellowish.

[0103] Pick one of the single colonies and perform Gram staining. After staining, it is purple, Gram-positive bacteria, short rod-shaped, and produces single cells.

[0104] 2. Physiological and biochemical characteristics:

[0105] Pick a single colony, refer to the "Common Bacteria Identification Manual", and carry out physiological and biochemical characteristics detection. The detection items and results are shown in Table 2.

[0106] Table 2 Experimental results of physiological and biochemical characteristics of strain WBRD00470-B3

[0107] ...

Embodiment 3

[0116] Example 3: Comparison of Fermentation Effects of Several Pretreatment Processes for Soybean Meal

[0117] 3.1 Pretreatment of soybean meal (provided by Yihai Taizhou Grain and Oil Industry Co., Ltd.)

[0118] Method 1. Add water and mix soybean meal (moisture content 12.89wt%), adjust the water content to 55wt%, and sterilize at 90°C for 30 minutes to obtain pretreated soybean meal-1;

[0119] Method 2. Soybean meal (moisture content 12.89wt%) was mixed with water, and the water content was adjusted to 55wt%, without sterilization, to obtain pretreated soybean meal-2;

[0120] Method 3. Soybean meal (moisture content 12.89wt%) is sterilized at 90°C for 30 minutes, then adjusted to 55wt%, and stirred evenly to obtain pretreated soybean meal-3.

[0121] Method 4. Soybean meal (moisture content 12.89wt%), add excess water, soak for a period of time, after completely absorbing water and swelling, vacuum filter to remove excess water, the water content of soybean meal is 65...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com