Culture medium and fermentation method for producing alginate lyase by fermentation of microvesicle bacterial genus

A technology of alginate lyase and fermentation medium, applied in the field of fermentation, can solve the problems of alginate lyase fermentation technology and fermentation kinetics, lack of brown algae and alginic acid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

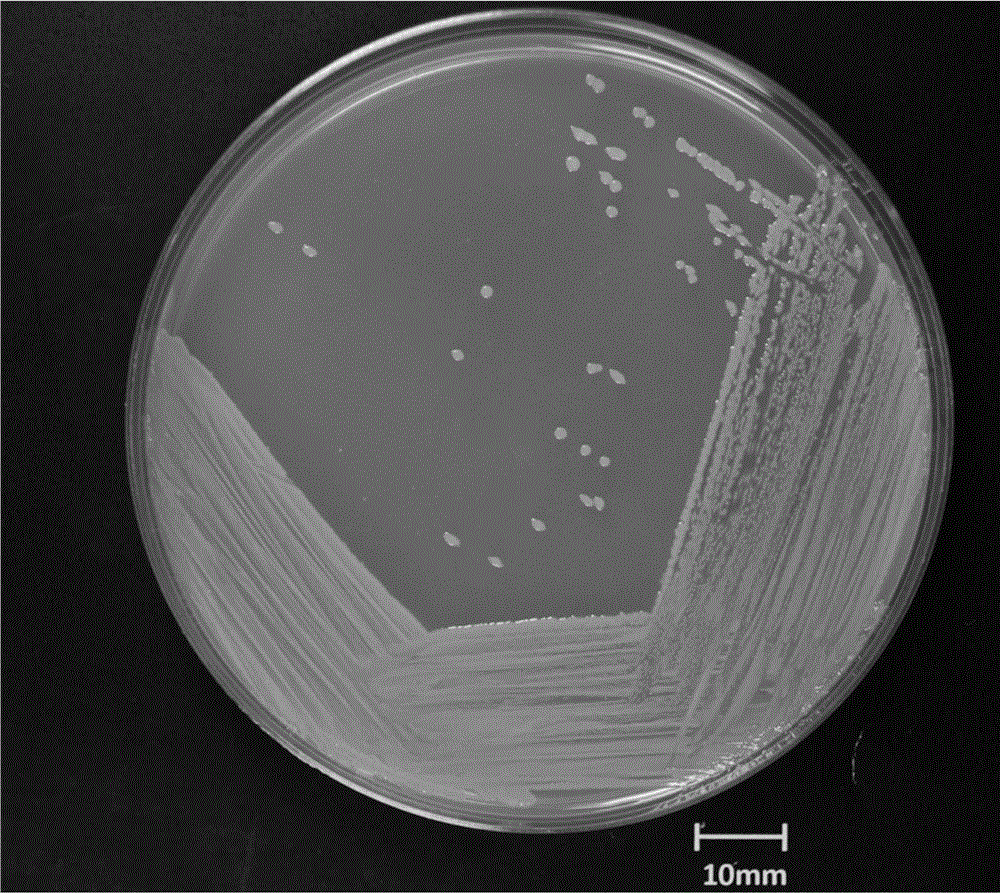

[0029] Example 1: Screening of Microvesicles ALW1

[0030] The present invention first isolates and obtains a strain of Microvesicles ( Microbulbifer sp.ALW1) (CICC deposit number: 23821), and the culture medium of the present invention can effectively increase the unit yield of alginate lyase produced by fermentation of Microvesicles. The kelp samples were added to shake flasks for culture, and the culture medium was gradiently diluted and coated on a plate. A single colony was picked and inserted into the fermentation medium with sodium alginate as the only carbon source. strains such as figure 1 shown. It was identified as the genus Microvesicle and named Microvesicle ALW1.

Embodiment 2

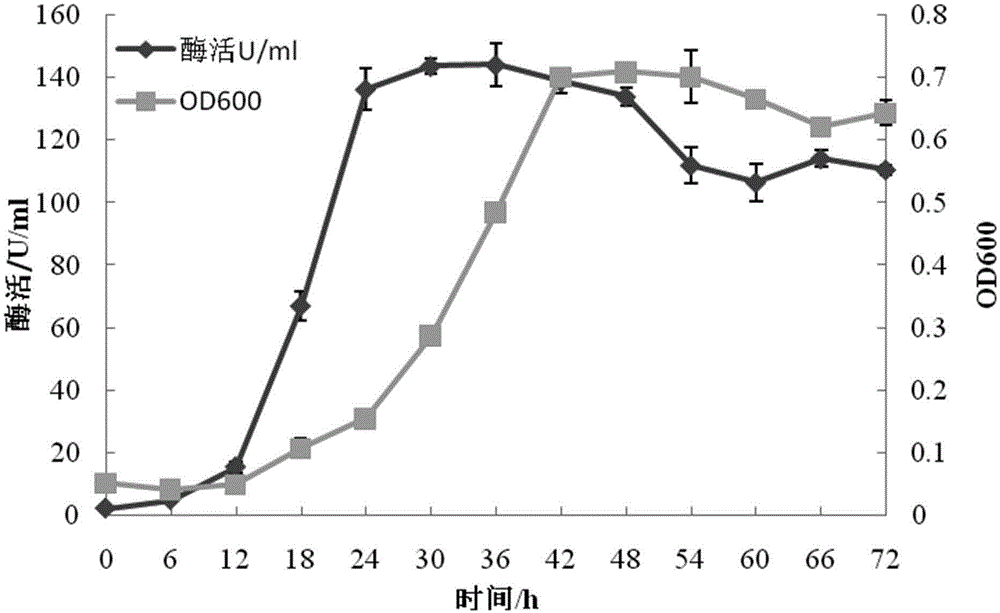

[0031] Example 2: Production of Alginate Lyase by Shake Flask Fermentation of Microvesicles ALW1

[0032] (1) Thaw the glycerol tube strains stored at -20°C and inoculate them in a 250mL shake flask filled with 50mL seed medium, and culture them at 25°C and 180r / min for 48h to obtain shake flask seed liquid. The seed medium is: sodium alginate 5g / L, peptone 5g / L, yeast powder 1g / L, NaCl 30 g / L, MgSO 4 ·7H 2 O 1g / L, K 2 HPO 4 2 g / L, FeSO 4 ·7H 2 O 0.01 g / L, (NH 4 ) 2 SO 4 5g / L, pH 7.5, sterilized at 121°C for 20 minutes;

[0033] (2) Put the cultivated shake flask seed solution into a 250 mL shake flask with 50 mL of fermentation medium at an inoculation amount of 5%, and ferment at 25°C and 180 r / min for 60 h to obtain alginate-containing lyase of fermentation broth. The fermentation medium is: sodium alginate 1g / L, NaCl 60 g / L, K 2 HPO4 3g / L, MgSO 4 ·7H 2 O 0.6g / L, FeSO 4 ·7H 2 O 0.06 g / L, pH 7.5, sterilized at 121°C for 20 min

[0034] (3) Evenly take 1.0 m...

Embodiment 3

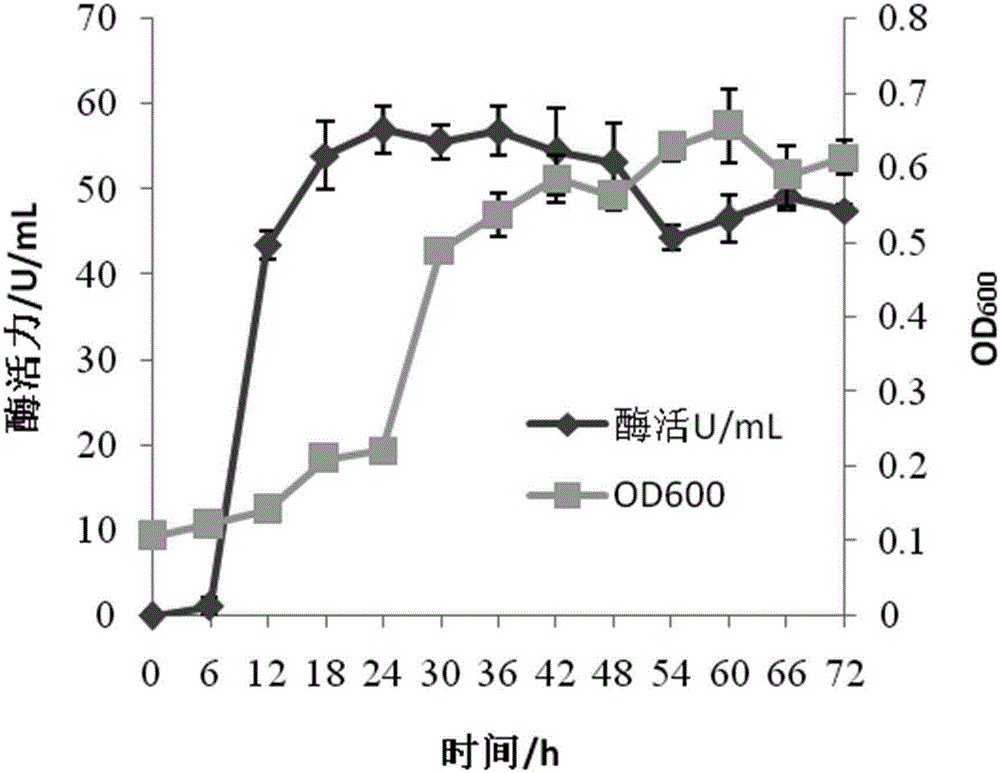

[0035] Example 3: Production of alginate lyase by tank fermentation of Microvesicles ALW1

[0036] (1) Thaw the glycerol tube strains stored at -20°C and inoculate them in a 250mL shake flask filled with 50mL seed medium, and culture them at 25°C and 180r / min for 48h to obtain the shake flask seed solution. The seed medium is: sodium alginate 5g / L, peptone 5g / L, yeast powder 1g / L, NaCl 30 g / L, MgSO 4 ·7H 2 O 1g / L, K 2 HPO 4 2 g / L, FeSO 4 ·7H 2 O 0.01 g / L, (NH 4 ) 2 SO 4 5g / L, pH 7.5, sterilized at 121°C for 20 minutes;

[0037] (2) Put the cultured shake flask seed liquid into a 5 L fermenter with 4 L fermentation medium according to the inoculum amount of 5%, and ferment at 25 °C and 100 r / min for 72 h to obtain alginate-containing alginate lyase fermentation broth. The fermentation medium is: sodium alginate 1g / L, NaCl 60 g / L, K 2 HPO 4 3g / L, MgSO 4 ·7H 2 O 0.6g / L, FeSO 4 ·7H 2 O 0.06 g / L, pH 7.5, sterilized at 121°C for 20 minutes, pH 7.5, sterilized at 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com