Secondary battery negative electrode material

A negative electrode material, secondary battery technology, applied in the field of electrochemical energy storage, can solve problems such as battery design difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

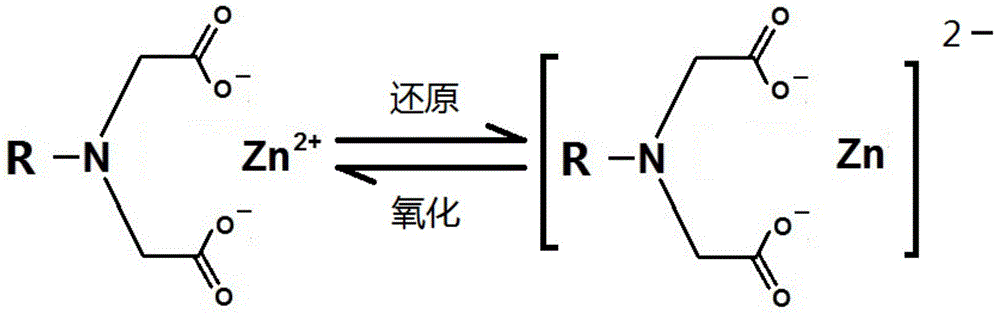

Problems solved by technology

Method used

Image

Examples

Embodiment 1 2

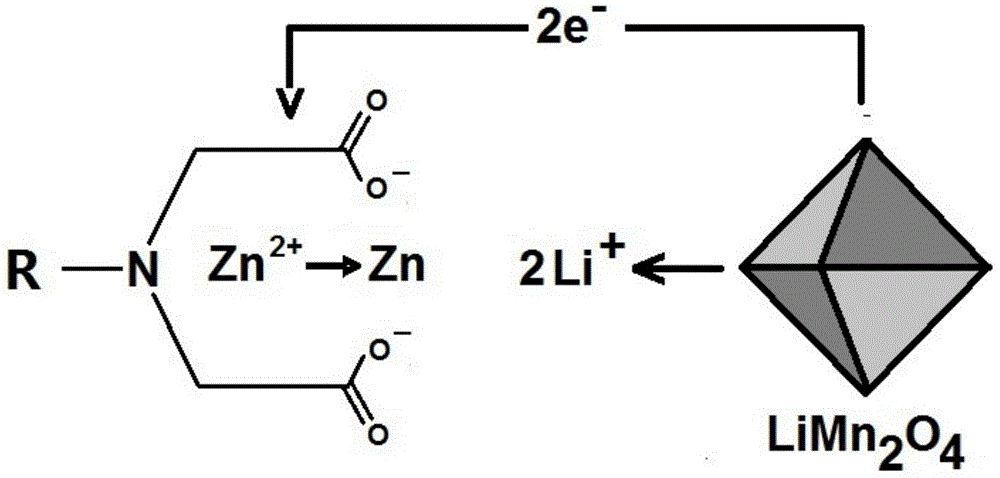

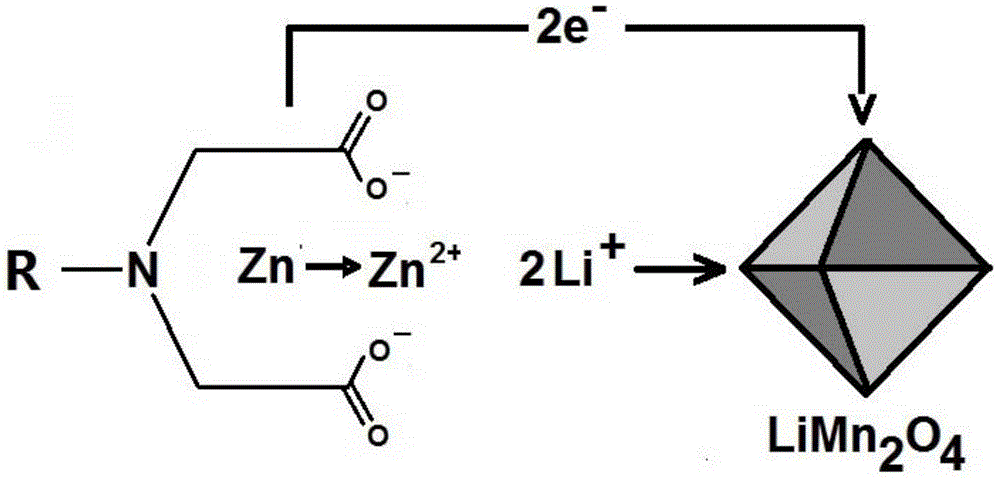

[0044] The preparation of embodiment 1 secondary battery

[0045] 1. Preparation of positive electrode sheet: LiMn 2 o 4 It is the positive electrode active material, according to the ratio of positive electrode active material 90%: conductive carbon black 6%: binder SBR (styrene-butadiene rubber latex) 2%: thickener CMC (sodium carboxymethyl cellulose) 2%, first put Mix CMC with a certain amount of water evenly, then add active material and conductive carbon black, stir for 2 hours, and finally add SBR and stir for 10 minutes to obtain positive electrode slurry. The positive electrode current collector is a 150 mesh SUS304 stainless steel mesh, and the positive electrode slurry is evenly coated on the positive electrode current collector, cut into a size of 10mmX10mm, and a weight of 50mg. Dry at 120°C for 12 hours to form a positive electrode sheet.

[0046] 2. Preparation of negative electrode active material: 1Kg of commercially available iminodiacetic acid chelating re...

Embodiment 2

[0052] The battery is manufactured in the same manner as in Example 1, except that the preparation method of the negative electrode active material is as follows:

[0053] Get 100 grams of sodium polyacrylate (molecular weight 10,000) and place it in 1L of deionized water, dissolve 400 grams of zinc sulfate in 1L of water, then pour it into the mixture of sodium polyacrylate and water, mix the solution for 10 hours, wash and filter, Then it is mixed with carbon black conductive agent so that the ratio is 8:1:1, and pressed into a pole piece, the mass per unit area is the same as that of the positive electrode, and the negative electrode is pasted on the zinc foil current collector.

[0054] The positive electrode of the battery uses the lithium manganate pole piece described in Example 1, the positive and negative electrodes have the same area, the mass ratio of the positive and negative electrodes is 1:1, and the electrolyte is a neutral lithium sulfate solution with pH=7.

...

Embodiment 3

[0058] The battery is manufactured in the same manner as in Example 1, except that the preparation method of the negative electrode active material is as follows:

[0059] Get 100 grams of polyacrylic acid weak acid adsorption resin (DIAION WK10, a kind of methacrylic acid type weak acid cation exchange resin, the structure is as follows Figure 7 Shown below) crushed to 400-mesh sieve, 400 grams of zinc sulfate was dissolved in 1L of water, poured into the above resin powder, the solution was mixed for 10 hours, washed and filtered, and then mixed with carbon black conductive agent, binder PTFE The powders are mixed at a ratio of 8:1:1, pressed into flakes, and pasted on the zinc foil current collector.

[0060] The positive electrode of the battery uses the lithium manganate pole piece described in Example 1, the size of the positive and negative pole pieces is the same, the mass ratio of the active material is 1:1, and the electrolyte is a neutral lithium sulfate solution w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com