Method for removing heavy metal in rice protein

A technology of rice protein and rice protein powder, which is applied in the field of removing heavy metals in rice protein, can solve the problems of poor taste and flavor, low yield, etc., and achieve the effects of cost saving, simple operation and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

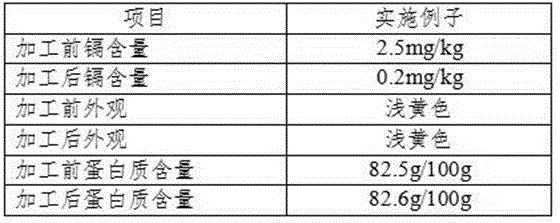

Embodiment 1

[0026] Take rice protein powder, add hot water to make slurry, mix well to obtain a slurry with a concentration of 20%; put the slurry through colloidal milling twice; then pickle with citric acid, wherein 20mg of lemon is added to 1kg of rice protein raw materials acid; then the slurry is homogenized 2 times, the slurry is fully contacted with the weak acid to replace the metal cadmium, and then neutralized with sodium bicarbonate until the solution is neutral; the neutralized slurry is passed through a fixed bed of chelating agent, so that The metal cadmium is adsorbed by the chelating agent, and the concentration of the slurry filtered under the fixed bed is adjusted to 30%; high-temperature sterilization is carried out at a high temperature of 120 ° C, and the sterilization time lasts for 5 seconds; then the sterilized slurry is spray-dried, The feed rate during spray drying is 30ml / min, the inlet air temperature is 180°C, and the outlet air temperature is 70°C.

[0027] ...

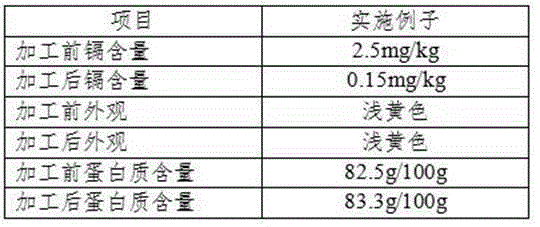

Embodiment 2

[0029] Take rice protein powder, add hot water for pulping and mixing to obtain a slurry with a concentration of 35%; put the slurry through colloidal milling twice; then pickle with citric acid, wherein 20mg of lemon is added to 1kg of rice protein raw material acid; then the slurry is homogenized 3 times, the slurry is fully contacted with the weak acid to replace the metal cadmium, and then neutralized with sodium bicarbonate until the solution is neutral; the neutralized slurry is passed through a fixed bed of chelating agent, so that The metal cadmium is adsorbed by the chelating agent, and the concentration of the slurry filtered under the fixed bed is adjusted to 30%; high-temperature sterilization is carried out at a high temperature of 120 ° C, and the sterilization time lasts for 5 seconds; then the sterilized slurry is spray-dried, The feed rate during spray drying is 30ml / min, the inlet air temperature is 180°C, and the outlet air temperature is 70°C.

[0030]

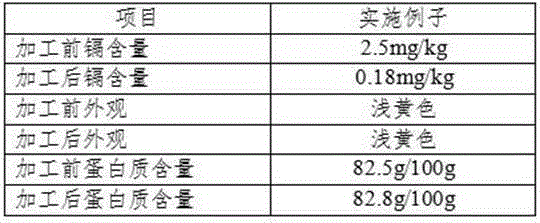

Embodiment 3

[0032] Take rice protein powder, add hot water to make slurry, mix well to obtain a slurry with a concentration of 50%; put the slurry through colloid mill twice; then pickle with citric acid, wherein 20mg of lemon is added to 1kg of rice protein raw material acid; then the slurry is homogenized 2 times, the slurry is fully contacted with the weak acid to replace the metal cadmium, and then neutralized with sodium bicarbonate until the solution is neutral; the neutralized slurry is passed through a fixed bed of chelating agent, so that The metal cadmium is adsorbed by the chelating agent, and the concentration of the slurry filtered under the fixed bed is adjusted to 30%; high-temperature sterilization is carried out at a high temperature of 120 ° C, and the sterilization time lasts for 5 seconds; then the sterilized slurry is spray-dried, The feed rate during spray drying is 30ml / min, the inlet air temperature is 180°C, and the outlet air temperature is 70°C.

[0033]

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com