Flame-retardant composite material for forest fire prevention fire-proof cover as well as preparation method of composite material

A flame-retardant composite material and fire-fighting technology, which is applied in chemical instruments and methods, non-polymer organic compound adhesives, lamination, etc., can solve the problems of high cost, low safety performance, and complicated processing of fire-fighting fire shelter materials , to achieve the effect of simple and practical structure, good sealing performance and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

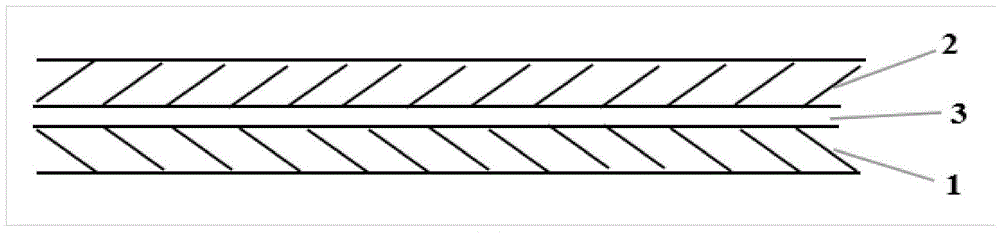

[0010] Specific embodiment 1: The flame-retardant composite material of the forest fire protection hood of this embodiment is composed of an outer layer, an adhesive layer and an inner layer; the outer layer is a special aluminum foil or aluminized film with a thickness of 0.13mm~ 0.15mm; the adhesive layer is a flame-retardant adhesive with a thickness of 0.02mm; the inner layer is a special glass fiber cloth with a thickness of 0.12mm.

[0011] The bulk density of the special aluminum foil or aluminized film in this embodiment is 280g / m 2 ; The bulk density of the flame-retardant adhesive is 200g / m 2 ; The bulk density of the special glass fiber cloth is 1000g / m 2 .

[0012] The special aluminum foil in this embodiment is a laminated metal aluminum foil; the special glass fiber cloth in this embodiment is a glass fiber cloth with 45 pieces×2 strands and a density of 12×14 mm.

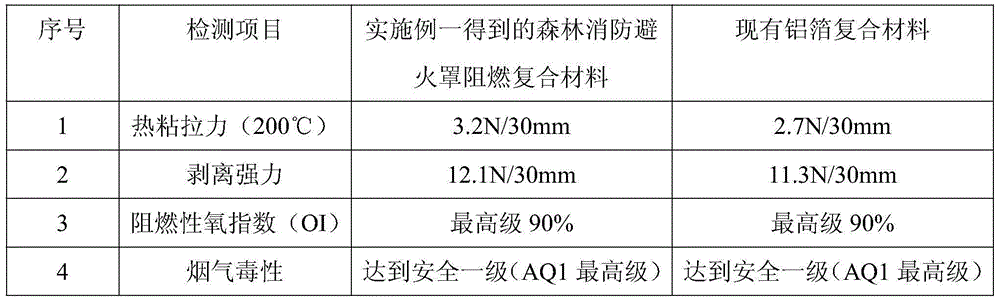

[0013] This embodiment uses the flame-retardant properties of the flame-retardant adhesive and the specia...

specific Embodiment approach 2

[0014] Specific embodiment two: this embodiment is different from specific embodiment one in that the aluminized film is formed by plating aluminum on the surface of the carrier; the carrier is basalt fiber, asbestos fiber or aramid fiber. The other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0015] Specific embodiment three: this embodiment is different from specific embodiment one or two in that: the flame retardant adhesive consists of 23 parts of butyl acrylate, 8 parts of methyl methacrylate, 8 parts of styrene, 2.5 parts of acrylic, It is made of 0.5 parts of acrylamide, 0.5 parts of benzoyl peroxide, 12 parts of ethanol, 45 parts of water and 0.5 parts of ammonia. The other steps and parameters are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com