A kind of multifunctional anion polymer compound additive and its preparation process

A technology of composite additives and negative ions, applied in building components, building insulation materials, buildings, etc., can solve the problems of not very considerable physical modification, no polymer chains, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] A kind of preparation method of multifunctional negative ion macromolecule compound additive is characterized in that comprising following processing steps:

[0039] a) Add the initiator and polar solvent in the above parts by weight to the organic solution of 1,3-butadiene under the condition of nitrogen flow, and react at a temperature of 20-70° C. for 60-300 minutes;

[0040] B) adding the nano-anion additive of above-mentioned parts by weight and stirring;

[0041] c) heating up to 50-100°C, adding the above-mentioned parts by weight of styrene and divinylbenzene, and reacting for 100-300 minutes;

[0042] D) adding the chain terminator reaction of above-mentioned parts by weight;

[0043] e) cooling to normal temperature, and pumping to constant weight in a vacuum oven;

[0044] F) adding the nano-anion additive and ethylene dichloride of the above-mentioned parts by weight to the product and stirring;

[0045] g) adding carbon tetrachloride and anhydrous alumin...

Embodiment 1

[0057] The following experiments were all carried out under the condition of nitrogen protection. A certain mass of polar solvent and n-butyllithium were added to 200ml of cyclohexane solvent and stirred evenly. The temperature was raised to 50°C, and 60.021g of 1,3- Butadiene, reacted for 180 minutes, added 50.276g of nano-anion additives with a particle size of 5nm-100nm, stirred evenly, raised the temperature to 70°C, added 10.191g of styrene and 15.121g of divinylbenzene, reacted for 180 minutes, added 1.095 g of ethanol, reacted for 60 minutes, cooled to normal temperature, put the product in a vacuum oven, baked at 90°C for 12 hours to constant weight to obtain 131.731 g of product, dissolved the product in a certain quality of dichloroethane, and added 60.984 Add a certain amount of carbon tetrachloride and anhydrous aluminum trichloride, and react at 30°C for 13 hours, then use acetone, dilute hydrochloric acid and water to dissolve It is washed, the product is put in ...

Embodiment 2

[0064] Use a grinder to grind the additive into 350-500 mesh particles, 500 grams of No. 90 bitumen from Sinopec as the base bitumen, add 12.5 grams of petroleum fractions with an aromatic content of 90.27% into the base bitumen, and stir at 160 degrees Celsius For 30 minutes, heat the base asphalt to 190 degrees Celsius, add 30 grams of additive particles, and shear at a high speed of 4500 rpm for 25 minutes by a high-speed shearer, then add 4.5 grams of sulfur powder, and then shear at a speed of 4500 rpm for 30 minutes , to obtain the final modified asphalt.

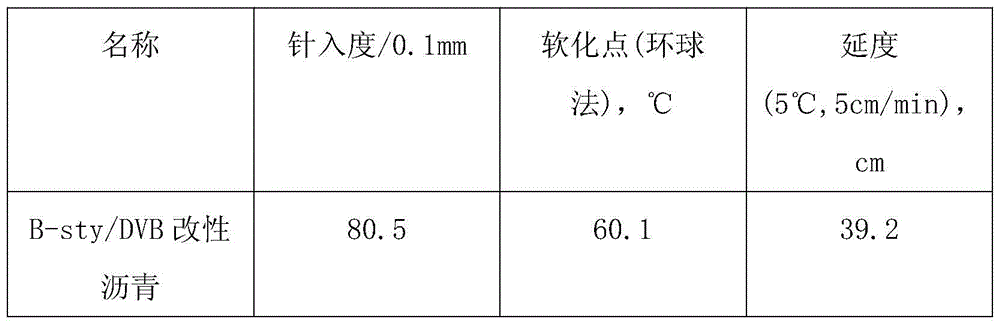

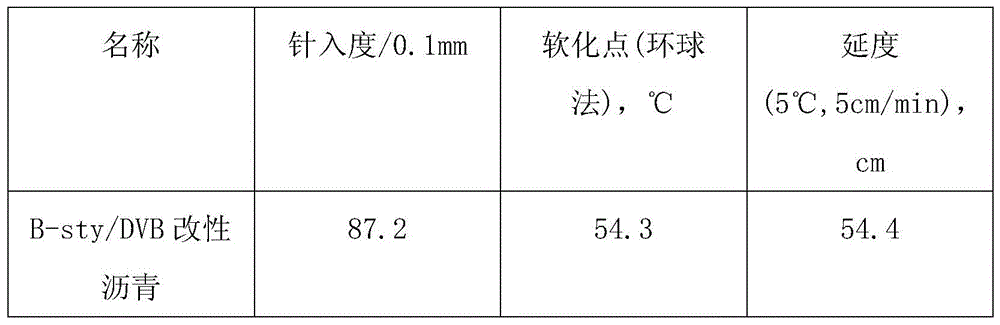

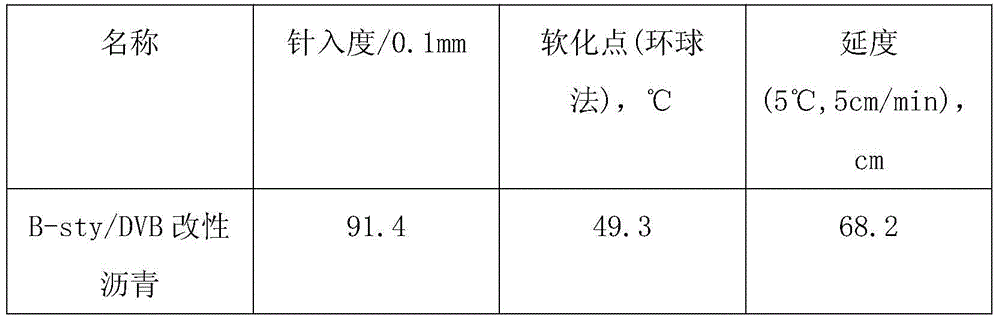

[0065] Use the national standard GB / T 4509-2010 method to test its penetration, use the national standard GB / T 4508-2010 method to test its ductility, use the national standard GB / T 4507-1999 method to test its softening point (ring and ball method), the test results are as follows :

[0066]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com