Thulium-holmium co-doped chlorosilicate upconversion light-emitting fluorescent powder as well as preparation method thereof and organic light-emitting diode

A chlorosilicate, phosphor technology, used in luminescent materials, chemical instruments and methods, semiconductor/solid-state device manufacturing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

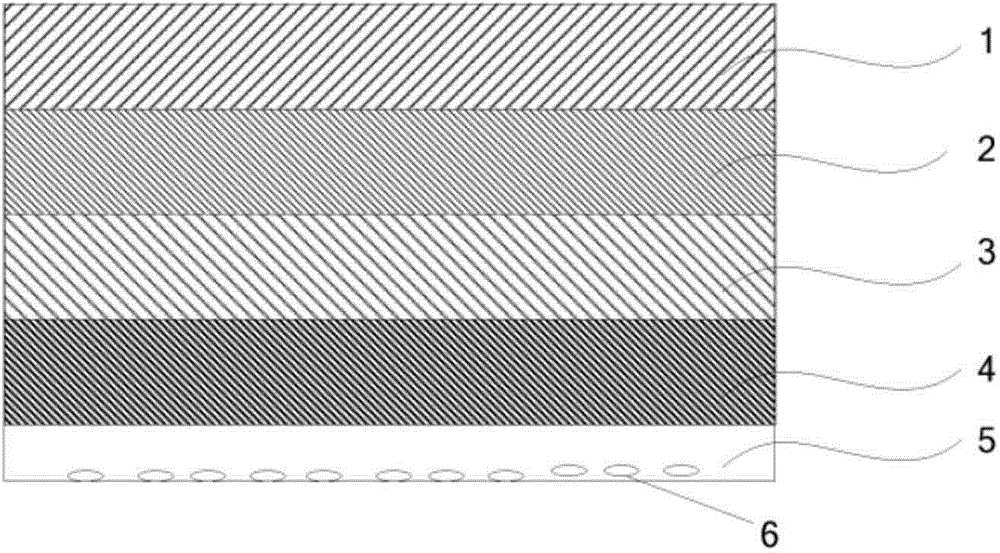

[0035] This embodiment also provides a method for preparing a thulium-holmium co-doped chlorosilicate upconversion luminescent phosphor, including the following steps:

[0036] (a) Weigh R according to the molar ratio of 2:2:x:y 2 CO 3 , SiO, Tm 2 o 3 and Ho 2 o 3 Powder;

[0037] (b) Dissolve the weighed powder in step (a) in hydrochloric acid HCl to prepare a 0.5-3 mol / L precursor solution, and add 0.005-0.05 mol / L polyethylene glycol to the precursor solution diol as a dispersant;

[0038] (c) introducing the precursor solution prepared in step (b) into the atomizer of the spray dryer for spray drying, wherein the reaction temperature of the atomizer is set at 100-220°C;

[0039] (d) Injecting 1 to 15 L / min of inert gas or reducing gas into the atomization device described in step (c);

[0040] (e) The precursor solution in the atomizer is atomized into an aerosol, and enters the reaction system of the spray dryer with the inert gas or the reducing gas, and the spra...

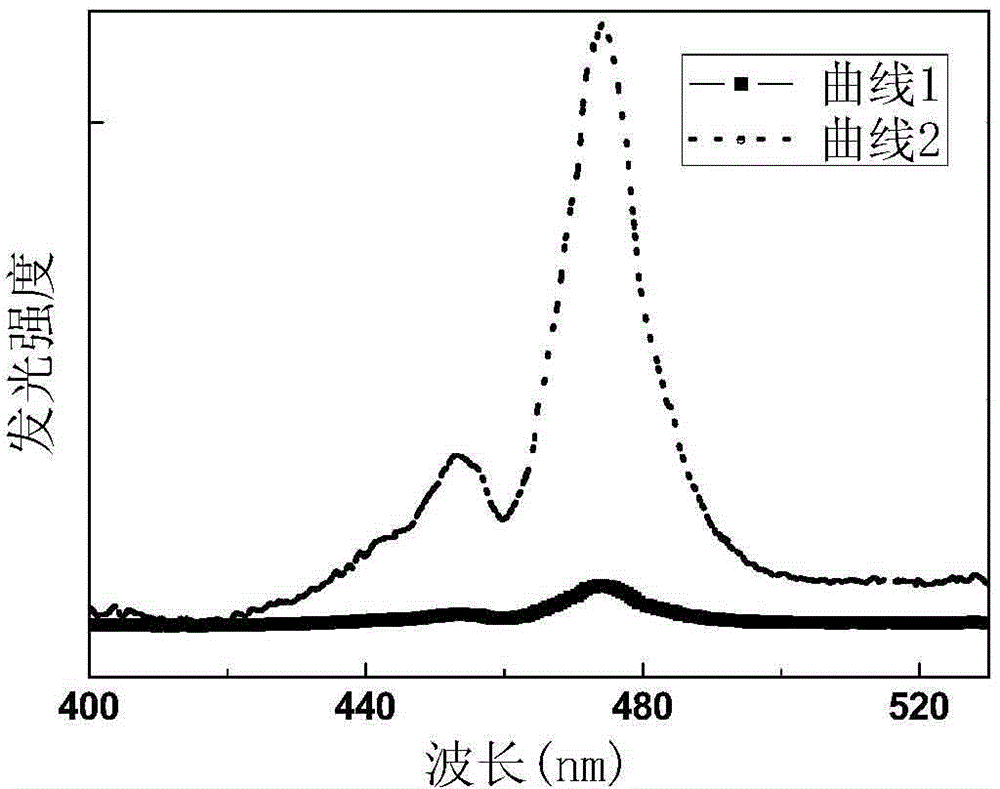

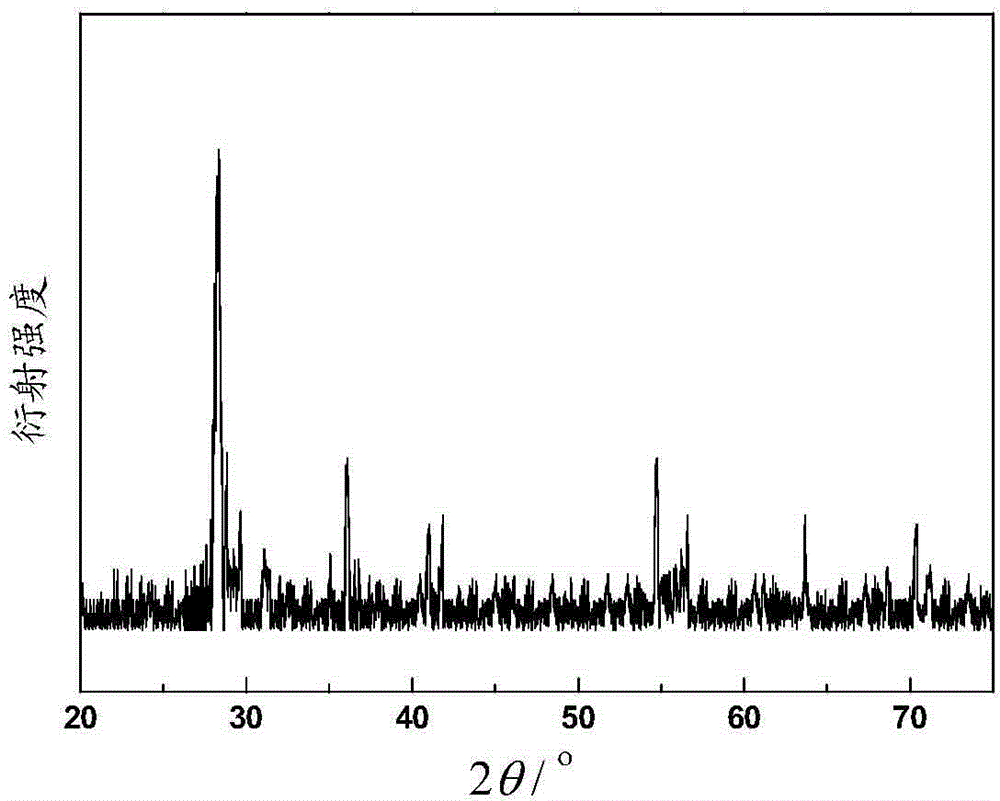

Embodiment 1

[0045] Thulium and holmium co-doped chlorosilicate upconversion luminescent phosphor Li in this embodiment 2 SiCl 6 : 0.03Tm 3+ ,0.01Ho 3+ The preparation method is as follows:

[0046] (a) Weigh Li according to the molar ratio of 2:2:0.03:0.01 2 CO 3 , SiO, Tm 2 o 3 and Ho 2 o 3 Powder;

[0047](b) Dissolve the weighed powder in step (a) in hydrochloric acid HCl to prepare a 1.5mol / L precursor solution, and add 0.01mol / L polyethylene glycol to the precursor solution as Dispersant;

[0048] (c) Introduce the precursor solution prepared in step (b) into the atomizer of the spray dryer for spray drying, wherein the inlet temperature of the atomizer is set to 180°C, and the outlet temperature is set to 110°C ;

[0049] (d) Introduce 5 L / min of argon into the atomization device described in step (c);

[0050] (e) The precursor solution in the atomizer is atomized into an aerosol, and enters the reaction system of the spray dryer with the argon gas introduced, and gene...

Embodiment 2

[0058] Thulium and holmium co-doped chlorosilicate upconversion luminescent phosphor Li in this embodiment 2 SiCl 6 : 0.06Tm 3+ ,0.04Ho 3+ The preparation method is as follows:

[0059] (a) Weigh Li according to the molar ratio of 2:2:0.06:0.04 2 CO 3 , SiO, Tm 2 o 3 and Ho 2 o 3 Powder;

[0060] (b) Dissolve the weighed powder in step (a) in hydrochloric acid HCl to prepare a 3mol / L precursor solution, and add 0.05mol / L polyethylene glycol to the precursor solution as a dispersion agent;

[0061] (c) Introduce the precursor solution prepared in step (b) into the atomizer of the spray dryer for spray drying, wherein the inlet temperature of the atomizer is set to 220°C, and the outlet temperature is set to 130°C ;

[0062] (d) Introduce 15 L / min of argon into the atomization device described in step (c);

[0063] (e) The precursor solution in the atomizer is atomized into an aerosol, and enters the reaction system of the spray dryer with the argon gas introduced, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com