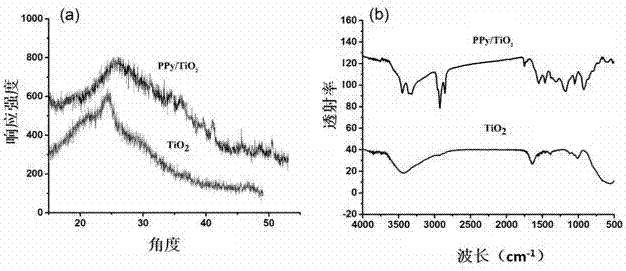

Polypyrrole/titanium dioxide frequency type thin film qcm gas sensor and preparation method thereof

A gas sensor, titanium dioxide technology, applied in the field of polypyrrole/titanium dioxide frequency thin film gas sensor, can solve the problem of low sensitivity, achieve low cost, good adhesion, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

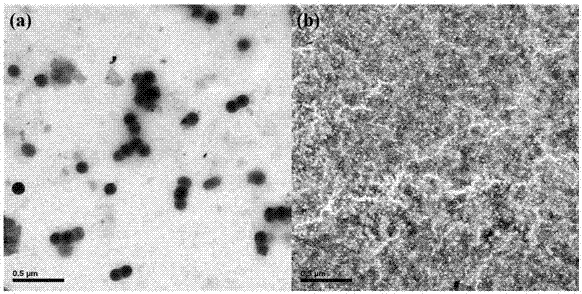

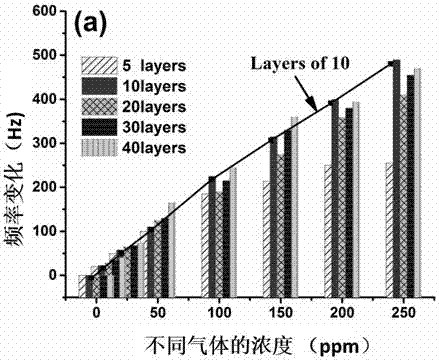

Method used

Image

Examples

Embodiment

[0037] The manufacture method of polypyrrole / titanium dioxide frequency type film gas sensor of the present invention comprises the following steps:

[0038] 1) QCM substrate cleaning

[0039] The QCM substrate was soaked and cleaned in absolute ethanol and acetone, and dried for later use.

[0040] 2) Modification of QCM substrate

[0041] 1. The QCM substrate was treated with Pilkard's reagent for 10 minutes, so that it was charged with negatively charged groups such as carboxyl groups, and the treated QCM substrate was rinsed with deionization for 1 minute and dried with nitrogen. 2. Immerse in 1%wt polydimethyldiallylammonium chloride (PDDA) aqueous solution for 5 minutes, take it out and rinse it with deionized water for 1 minute and dry it with nitrogen. 3. Immerse the QCM substrate in sodium toluene sulfonate (PSS) for 5 minutes, take it out and rinse it with deionization for 1 minute and dry it with nitrogen. Repeat step 2 and step 3 twice in sequence to modify the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com