Quantitative detecting method for interface reaction degree of aluminum-carbon composite material

A quantitative detection method and technology of carbon composite materials, applied in the field of quantitative determination of the degree of carbon/aluminum interface reaction, rapid field, can solve problems such as misjudgment, insufficient scale accuracy, increased misjudgment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

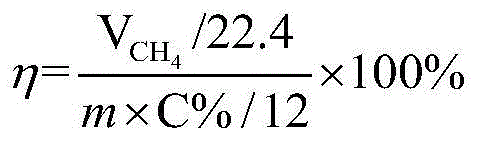

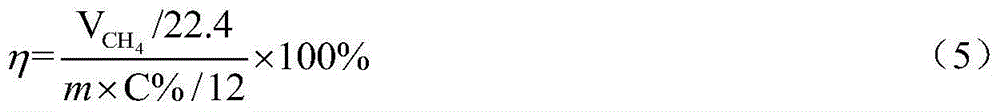

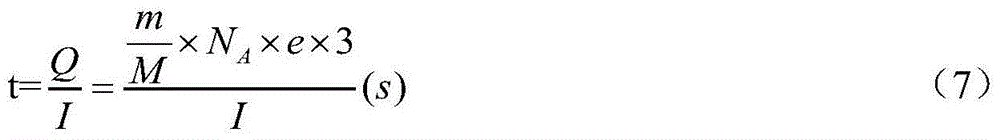

Method used

Image

Examples

Embodiment 1

[0040] CNT / Al composites sintered at 570°C, 600°C, and 630°C for 2h were prepared by powder metallurgy process. Thin slice samples of a certain size were cut out respectively, their masses were weighed, and electrodes were prepared. Nitrogen gas was introduced before the reaction started to exhaust the air in the device. The current was set to 2A to start the electrolysis reaction. After the reaction is finished, continue to feed nitrogen, and completely collect the remaining generated gas in the device. After the generated gas was completely collected, 50 mL of CO was injected into the vacuum bag as the calibration gas. Then extract a certain volume of mixed gas for gas chromatographic analysis. The obtained results are shown in Table 1:

[0041] Table 1 Test results of CNT / Al with different degrees of interfacial reaction

[0042] sample

material composition

Sintering conditions

CH 4

CO

Response degree η...

Embodiment 2

[0050] Graphene / Al composites sintered at 570 °C, 600 °C, and 630 °C for 2 h were prepared by powder metallurgy process. Thin slice samples of a certain size were cut out respectively, their masses were weighed, and electrodes were prepared. Nitrogen gas was introduced before the reaction started to exhaust the air in the device. The current was set to 2A to start the electrolysis reaction. After the reaction is finished, continue to feed nitrogen, and completely collect the remaining generated gas in the device. After the generated gas was completely collected, 50 mL of CO was injected into the vacuum bag as the calibration gas. Then extract a certain volume of mixed gas for gas chromatographic analysis. The obtained results are shown in Table 4:

[0051] Table 4 Test results of graphene / Al with different degrees of interfacial reaction

[0052] sample

material composition

Sintering conditions

calibration gas

CH 4

CO

Res...

Embodiment 3

[0060] Diamond / Al composites sintered at 570°C, 600°C, and 630°C for 2h were prepared by powder metallurgy process. Thin slice samples of a certain size were cut out respectively, their masses were weighed, and electrodes were prepared. Nitrogen gas was introduced before the reaction started to exhaust the air in the device. The current was set to 2A to start the electrolysis reaction. After the reaction is finished, continue to feed nitrogen, and completely collect the remaining generated gas in the device. After the generated gas was completely collected, 50 mL of CO was injected into the vacuum bag as the calibration gas. Then extract a certain volume of mixed gas for gas chromatographic analysis. The obtained results are shown in Table 7:

[0061] Table 7 Test results of diamond / Al with different interface reaction degrees

[0062] sample

[0063] 2

[0064] A diamond / Al test sample with a mass of 2 g was taken and dissolved by chemical reaction an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com