Degradable hydrate accelerant and preparation method and application thereof

A technology for accelerators and gas hydrates, which is applied in the field of preparation of degradable high-efficiency accelerators, can solve the problems of insufficient hydrate promotion efficiency, low reuse rate, and hindered hydrates, so as to achieve high-efficiency production, low cost, and The effect of lowering the balance point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

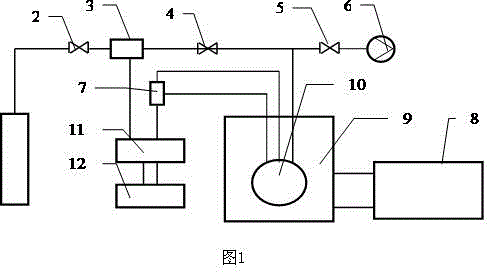

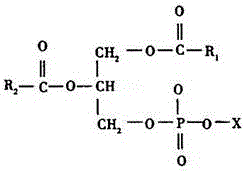

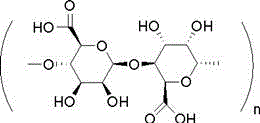

Method used

Image

Examples

Embodiment 1

[0041] Table 1 Experimental results

[0042] Experiment number Accelerator concentration (ppm) Induction time (min) Phase equilibrium pressure (MPa) 1 300 13.3 2.12 2 400 12 2.04 3 500 9.6 2.05 4 600 8.0 1.97 5 700 6.8 1.86 6 800 6.7 1.75

Embodiment 2

[0045] Table 2 Experimental results

[0046] Experiment number Accelerator concentration (ppm) Induction time (min) Phase equilibrium pressure (MPa) 1 300 12.8 2.00 2 400 11.6 1.89 3 500 7.9 1.80 4 600 6.4 1.73 5 700 4.9 1.72 6 800 4.5 1.72

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com