Method for recovering organic silicon monomer from silicone rubber wastes

A technology of silicone rubber and organosilicon, applied in the direction of silicon organic compounds, etc., can solve the problems of environmental pollution, waste of resources, etc., achieve the effect of less secondary pollutants, solve the problem of recycling, and recover products with high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

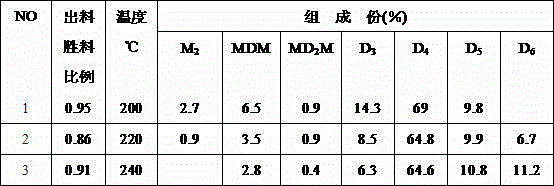

Examples

Embodiment 1

[0022] Put 100 kilograms of distilled water into a 200 liter mixing tank, then slowly dissolve 55 kilograms of potassium hydroxide into the distilled water, after dissolving, put 5 kilograms of sodium dodecylbenzenesulfonate surfactant, stir and mix to form Homogenize the solution, slowly drop into 10 kg of saturated iron chloride solution, stir at room temperature for 1.5 hours, take it out and pour it into a ball mill to grind to obtain a Fe composite catalyst for later use. Wash and cut 100 kilograms of silicone rubber waste into a size smaller than 2×2×2cm, add 8 kilograms of Fe composite catalyst, stir evenly before putting it directly into a multi-tubular reaction tank, and raise the temperature of the tank under normal pressure Carry out catalytic cracking. When the temperature reaches 350°C, cracking begins to occur. When the temperature rises to 400-450°C, a large amount of products are produced and condensed. The final temperature is 500-600°C. After 180 minutes of re...

Embodiment 2

[0025] Put 100 kilograms of distilled water into a 200 liter mixing tank, then slowly dissolve 55 kilograms of sodium hydroxide into the distilled water, after dissolving, put 5 kilograms of sodium dodecylbenzenesulfonate surfactant, stir and mix to form Uniform solution, slowly drop into 10 kg of copper chloride saturated solution, stir at room temperature for 2 hours, take it out and pour it into a ball mill to grind to prepare a Cu composite catalyst for future use. Wash and cut 100 kg of silicone rubber waste into a size smaller than 2×2×2cm, add 5 kg of Cu composite catalyst, stir evenly, and then put it directly into a multi-tubular reaction tank, and raise the temperature of the tank under normal pressure Carry out catalytic cracking. When the temperature reaches 350°C, cracking begins to occur. When the temperature rises to 400-450°C, a large amount of products are produced and condensed. The final temperature is 500-600°C. After 180 minutes of reaction, 60 kg of crude ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com