Multifunctional open-cell foamed polymer particles and preparation method thereof

A technology of foaming polymers and polymer particles, which is applied in the field of multifunctional open-cell foamed polymer particles and its preparation, achieving the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

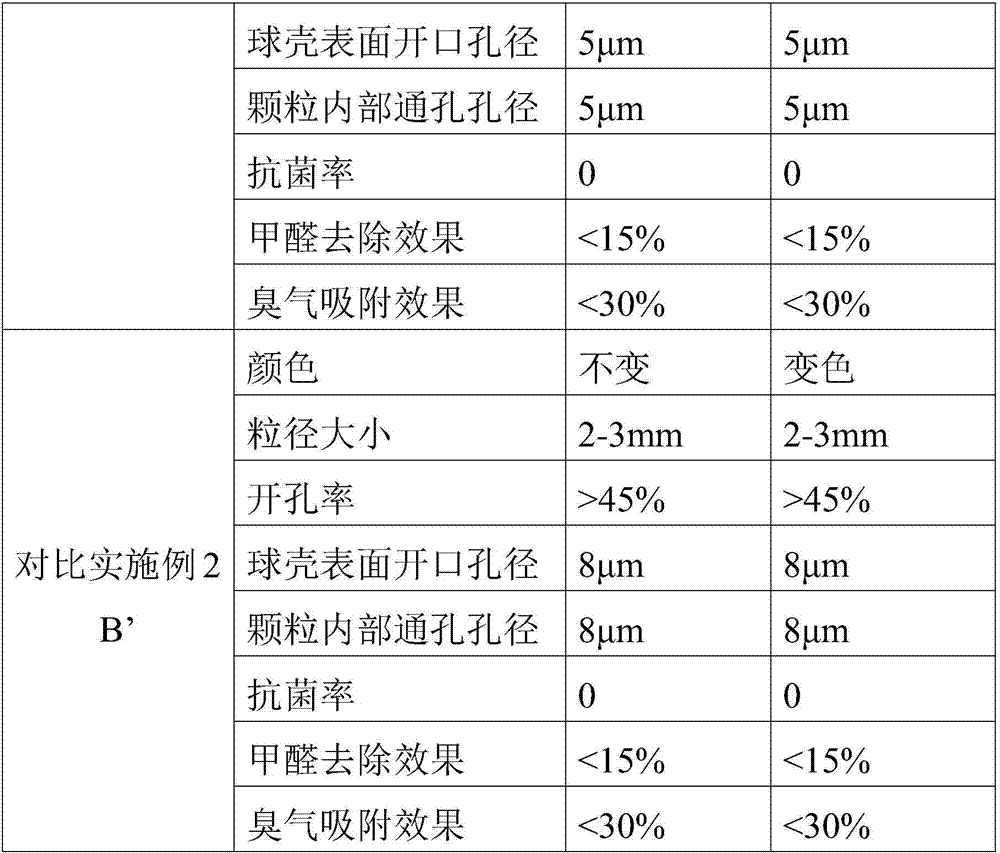

Examples

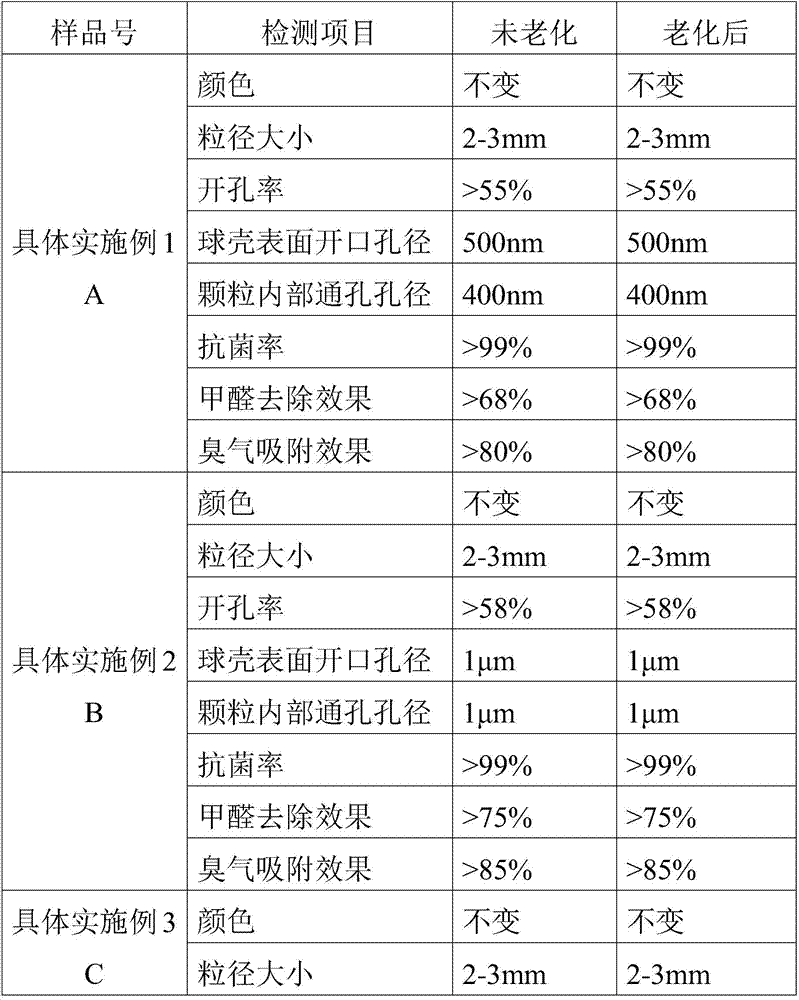

specific Embodiment 1

[0025] Multifunctional open-cell foamed polymer particles A, including the following components according to the total mass percentage of the multifunctional open-cell foamed polymer particles: 93.7% polyethylene resin, 4% nano-zinc oxide, 3‰ of antioxidant , polyethylene wax 1%, silane coupling agent 1%, wherein said antioxidant consists of four-[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and three- (2,4-Di-tert-butyl)phenyl phosphite compounded according to the mass ratio of 1:1. The particle size of nano zinc oxide is 50nm.

[0026] A method for preparing multifunctional open-cell foamed polymer particles, specifically:

[0027] (1) Weigh each material according to the above ratio, first put polyethylene resin, polyethylene wax and silane coupling agent into a high-speed mixer in sequence, and mix for 2-10 minutes at a speed of 1000-1500r / min to obtain the first Mixed material; then continue to add the weighed nano-zinc oxide and antioxidant i...

specific Embodiment 2

[0031] Multifunctional open-cell foamed polymer particles B, including the following components in terms of the total mass percentage of the multifunctional open-cell foamed polymer particles: 91.5% polyvinyl chloride resin, 3% nano-titanium dioxide, and 2% nano-zinc oxide , antioxidant 5‰, stearic acid 2%, titanate coupling agent 1%, wherein said antioxidant consists of four-[β-(3,5-di-tert-butyl-4-hydroxyphenyl) Propionate] pentaerythritol ester and tri-(2,4-di-tert-butyl) phenyl phosphite compounded according to the mass ratio of 1:1. The particle size of the nano-titanium dioxide is 20nm, and the particle size of the nano-zinc oxide is 50nm.

[0032] A method for preparing multifunctional open-cell foamed polymer particles, specifically:

[0033] (1) Weigh each material according to the above ratio, first put the polyvinyl chloride resin, stearic acid and titanate coupling agent into the high-speed mixer in turn, and mix for 2-10 minutes at a speed of 1000-1500r / min Obta...

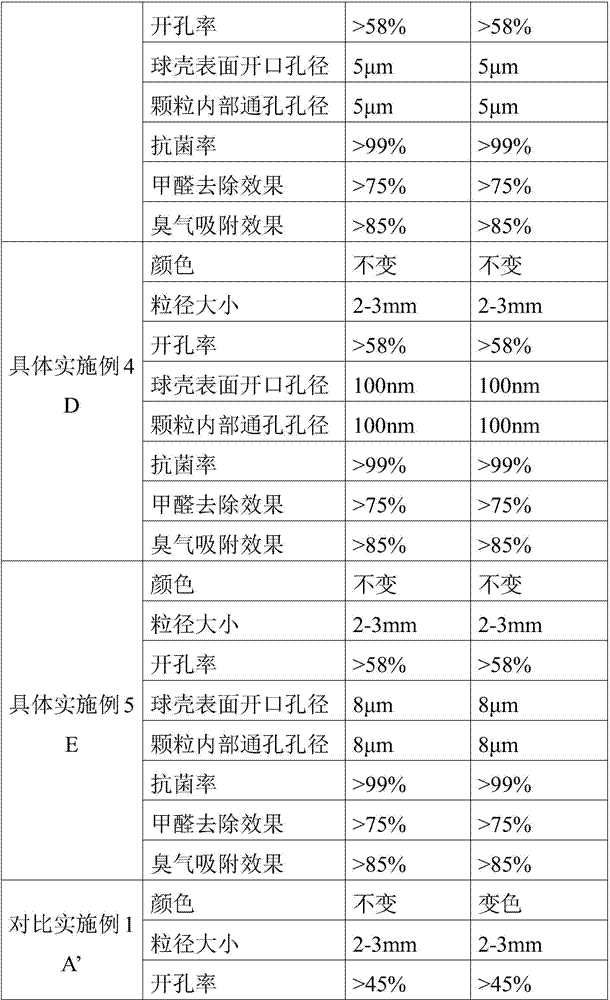

specific Embodiment 3

[0037] Multifunctional open-cell foamed polymer particles C, including the following components in terms of the total mass percentage of the multifunctional open-cell foamed polymer particles: 90.5% polyurethane resin, 5% nanometer zinc sulfide powder, 5% antioxidant ‰, ethylene bis stearamide 2%, aluminate coupling agent 2%, wherein said antioxidant consists of four-[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid ] Pentaerythritol ester and tri-(2,4-di-tert-butyl) phenyl phosphite are compounded according to the mass ratio of 1:1. The particle size of nano zinc sulfide is 80nm.

[0038] A method for preparing multifunctional open-cell foamed polymer particles, specifically:

[0039] (1) Weigh each material according to the above ratio, first put the polyurethane resin, ethylene bisstearamide and aluminate coupling agent into the high-speed mixer in sequence, and mix 2-10 at the speed of 1000-1500r / min Minutes to obtain the first mixture; then continue to add the weigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com