Preparation method for molecularly imprinted solid-phase extraction columns of anthraquinone sensitizing disperse dyes

A technology of solid phase extraction column and solid phase extraction column, which is applied in the field of preparation of molecularly imprinted solid phase extraction column of anthraquinone sensitized disperse dyes, can solve the problems such as no reports of molecularly imprinted solid phase extraction column, and achieve High selectivity and enrichment capacity, strong selectivity and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

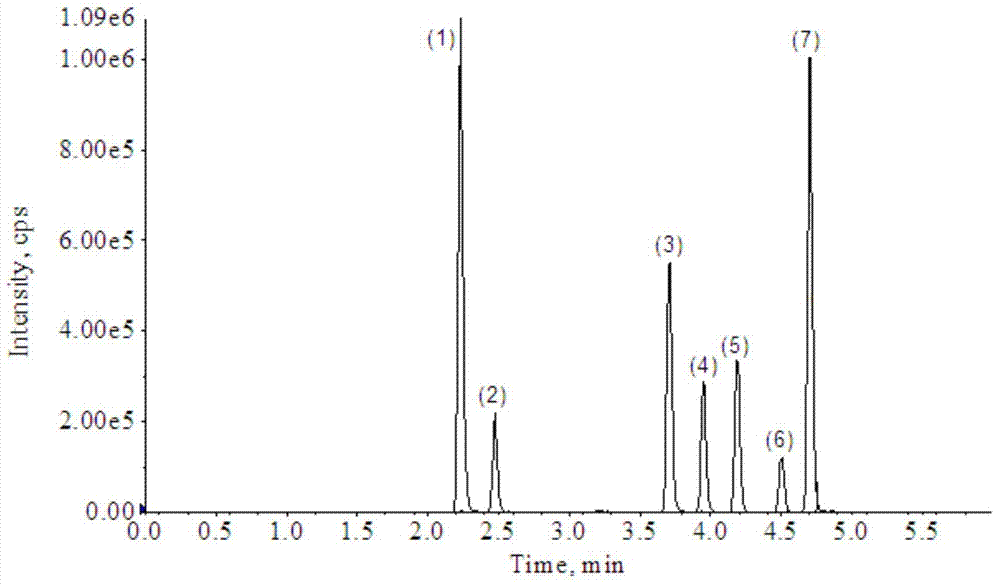

Embodiment 1

[0029] The preparation method of the anthraquinone-type sensitizing disperse dye molecularly imprinted solid-phase extraction column in this example includes the following steps:

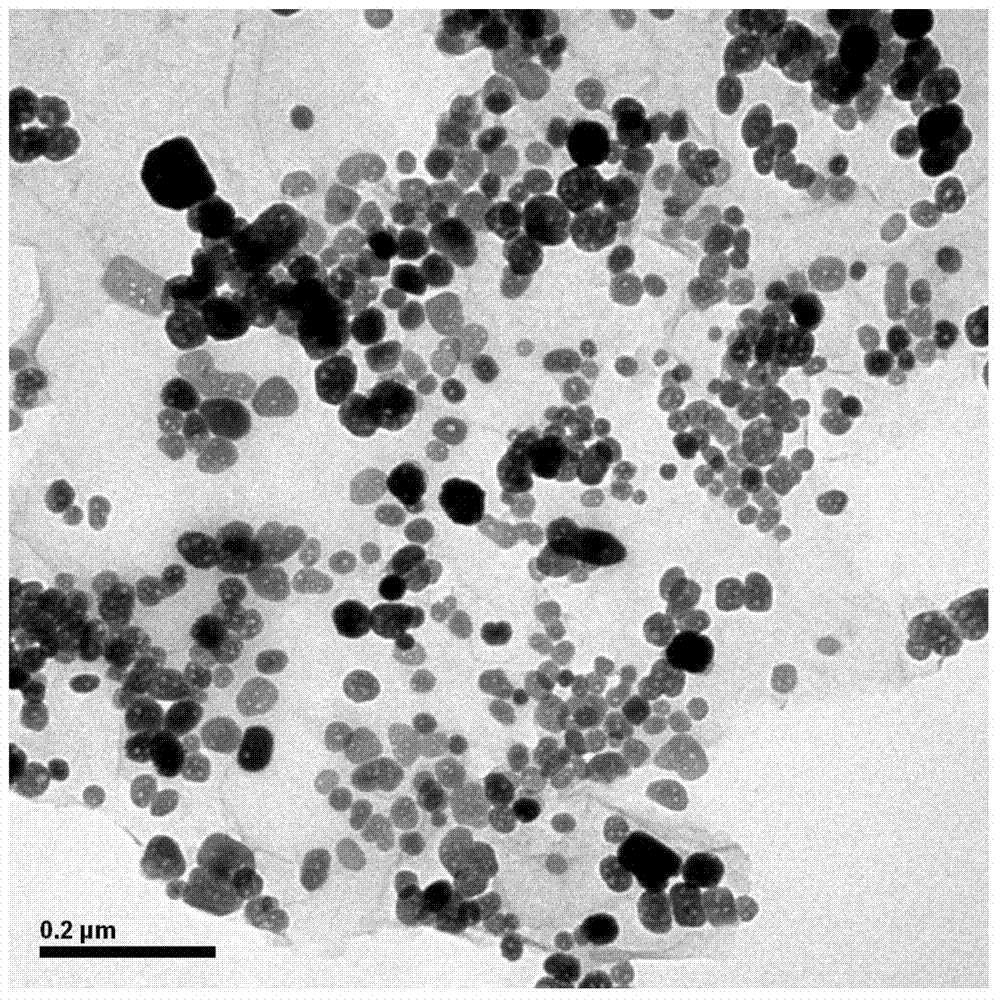

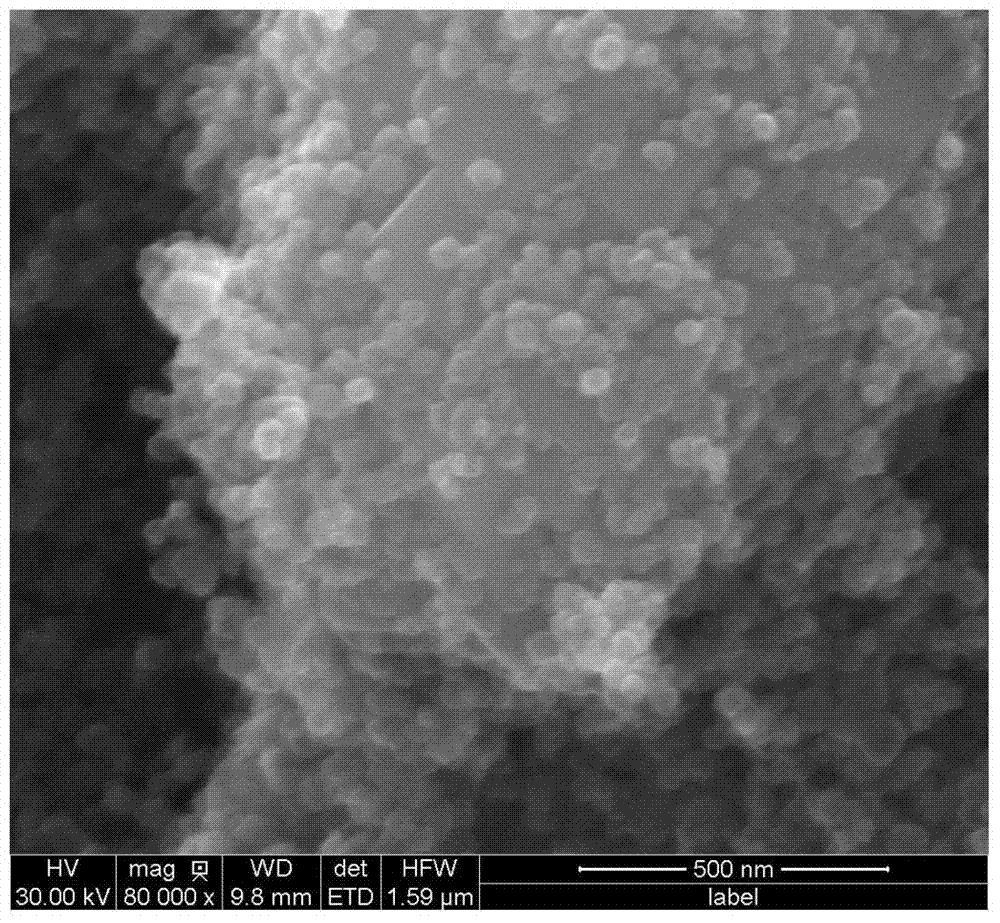

[0030] Preparation of anthraquinone-sensitized disperse-dyed magnetic graphene-based molecularly imprinted polymers:

[0031] (a) FeSO 4 and FeCl 3 ·6H 2 O is dissolved in 100 mL of water to give Fe 2+ , Fe 3+ Molar concentrations of 0.2mol / L, 0.6mol / L solutions, the solution was ultrasonically dispersed for 15 minutes, then 50 mg of graphene was added, and the ultrasonic dispersion was continued for 1 hour;

[0032] (b) Add 0.1moL of anthraquinone-type sensitizing disperse dye template Molecular Disperse Blue 1 to the resultant of step (a), and adjust the pH value to 11 with ammonia water at 80°C, then at 80°C, at 600r / min Stir the reaction for 1 h to obtain a product with black solid powder;

[0033] (c) Carry out magnetic separation to the product of step (b), and the obtained black solid p...

Embodiment 2

[0040] The preparation method of the anthraquinone-type sensitizing disperse dye molecularly imprinted solid-phase extraction column in this example includes the following steps:

[0041] Preparation of anthraquinone-sensitized disperse-dyed magnetic graphene-based molecularly imprinted polymers:

[0042] (a) FeSO 4 and FeCl 3 ·6H 2 O is dissolved in 100 mL of water to give Fe 2+ , Fe 3+ Molar concentrations of 0.18mol / L, 0.58mol / L solutions, the solution ultrasonic dispersion 10min after adding 45mg graphene, and continue ultrasonic dispersion 1.5h;

[0043] (b) Add 1.0 mol of anthraquinone-type sensitizing disperse dye template Molecular Disperse Blue 3 to the resultant of step (a), and adjust the pH value to 10 with ammonia water at 82°C, then at 82°C, at 620r / min Stirring and reacting for 1.2h, the product with black solid powder was obtained;

[0044] (c) Carry out magnetic separation to the product of step (b), and the black solid powder obtained is washed successi...

Embodiment 3

[0050] The preparation method of the anthraquinone-type sensitizing disperse dye molecularly imprinted solid-phase extraction column in this example includes the following steps:

[0051] Preparation of anthraquinone-sensitized disperse-dyed magnetic graphene-based molecularly imprinted polymers:

[0052] (a) FeSO 4 and FeCl 3 ·6H 2 O is dissolved in 100 mL of water to give Fe 2+ , Fe 3+ Molar concentrations of 0.22mol / L, 0.62mol / L solutions, the solution was ultrasonically dispersed for 20min, then 55mg of graphene was added, and the ultrasonic dispersion was continued for 2h;

[0053] (b) Add 0.5 mol of anthraquinone-type sensitizing disperse dye template Molecular Disperse Blue 7 to the resultant of step (a), and adjust the pH value to 12 with ammonia water at 80°C, then at 80°C, at 650r / min Stirring and reacting for 1.5h, the product with black solid powder was obtained;

[0054] (c) Carry out magnetic separation to the product of step (b), and the black solid powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com