Device and method for quickly extracting semisolid melt

A semi-solid, melt technology, applied in the sampling device and other directions, can solve the problems of slow cooling speed, inability to correspond to temperature process parameters, less solid phase, etc., to achieve the effect of strong cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Melt the A356 aluminum alloy in a resistance furnace, degas and refine the alloy melt at 720-730°C, transfer the refined A356 alloy melt to a graphite crucible preheated at 400°C, and put the graphite crucible into In the electromagnetic stirrer, the semi-solid slurry is prepared by electromagnetic stirring method. Electromagnetic stirring process parameters are stirring current 10-15A, frequency 50HZ.

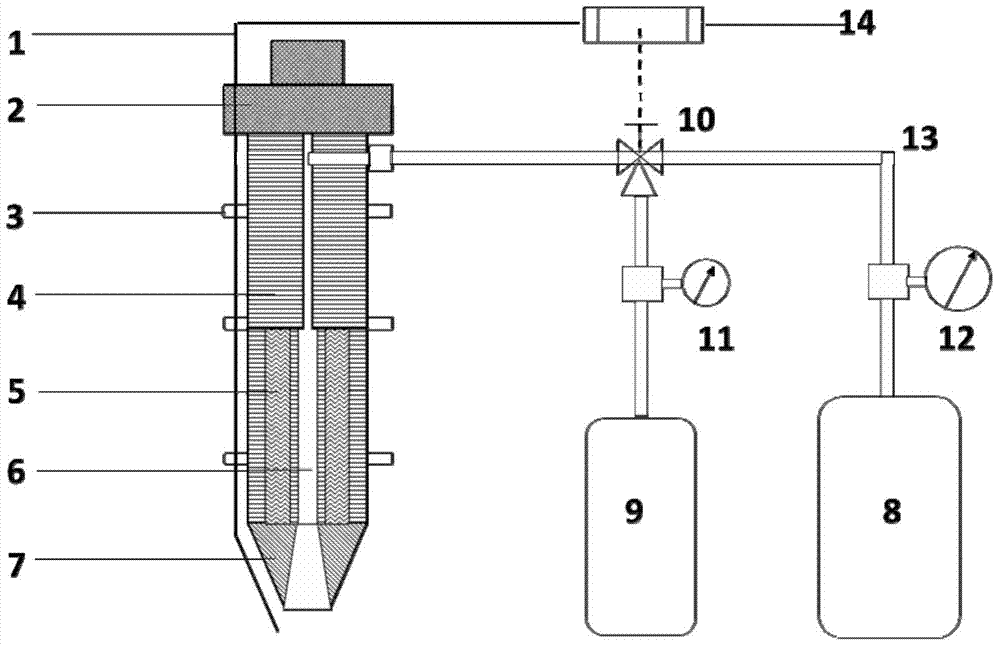

[0031] The high cooling speed quenching copper mold 4 is assembled through the top screwing device 2 and the locking device 3, the thermocouple 1 is installed, the temperature acquisition and control system 14 is turned on first, and the high temperature resistant quenching nozzle 7 is inserted into the A356 alloy melt , and then open the hydraulic three-way valve 10 to feed inert gas to discharge the metal melt in the copper mold. When the temperature reaches 600°C, the alloy melt is a semi-solid melt, and the temperature acquisition and control system 14 controls the ...

Embodiment 2

[0033] Melt the 7075 aluminum alloy in a resistance furnace, degas and refine the alloy melt at 730-740°C, transfer the refined 7075 alloy melt to a graphite crucible preheated at 400°C, and put the graphite crucible into In the electromagnetic stirrer, the semi-solid slurry is prepared by electromagnetic stirring method. Electromagnetic stirring process parameters are stirring current 10-15A, frequency 50HZ.

[0034] The high cooling speed quenching copper mold 4 is assembled through the top screwing device 2 and the locking device 3, the thermocouple 1 is installed, the temperature acquisition and control system 14 is turned on first, and the high temperature resistant quenching nozzle 7 is inserted into the 7075 alloy melt , and then open the hydraulic three-way valve 10 to feed inert gas and discharge the metal melt in the copper mold. When the temperature reaches 620°C, the alloy melt is a semi-solid melt, and the temperature acquisition and control system 14 controls the...

Embodiment 3

[0036] Melt the A356 aluminum alloy in a resistance furnace, degas and refine the alloy melt at 720-730°C, transfer the refined A356 alloy melt to a graphite crucible preheated at 400°C, and put the graphite crucible into In the electromagnetic stirrer, the semi-solid slurry is prepared by electromagnetic stirring method. Electromagnetic process parameters are stirring current 10-15A, frequency 50HZ.

[0037] The high cooling rate quenching copper mold 4 is assembled through the top screwing device 2 and the locking device 3, the thermocouple 1 is installed, and the three sets of devices that have been prepared are combined, as shown in FIG. figure 2shown. First turn on the temperature acquisition and control system 14, insert three sets of high-temperature-resistant quenching nozzles 7 into the center, 1 / 2 radius and edge positions of the A356 alloy melt, and then open the hydraulic three-way valve 10 to feed inert gas , discharge the metal melt in the three sets of copper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com