Method and device for degrading nitrobenzene waste water in high gravity field through catalytic ozonation

A technology of ozone degradation and supergravity field, applied in chemical instruments and methods, water treatment of special compounds, oxidized water/sewage treatment, etc., can solve problems such as ferrous ion precipitation, improve oxidation efficiency and prevent iron precipitation , the effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

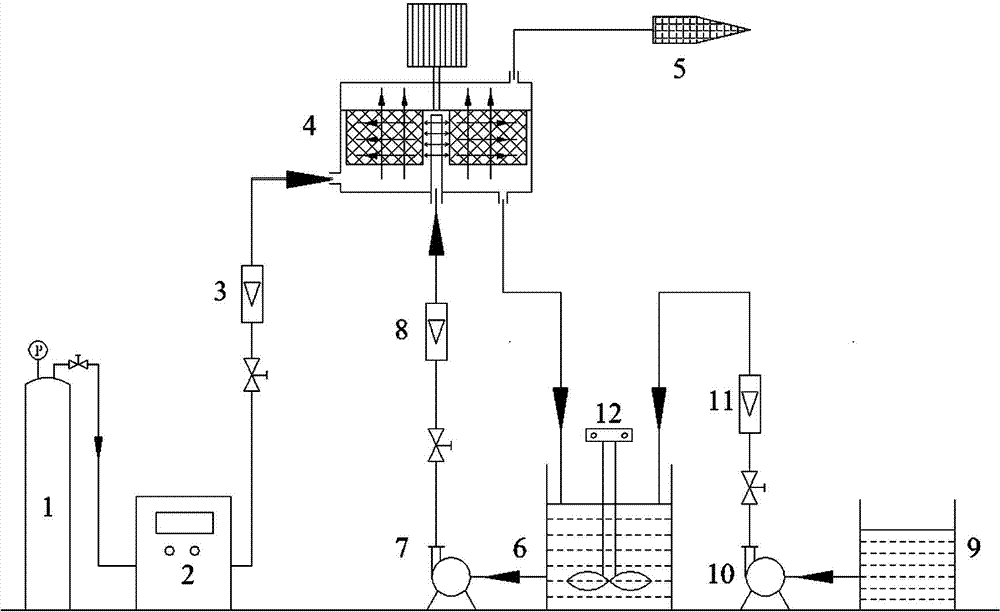

[0028] Example 1: Using figure 1 The flow shown is for the treatment of wastewater containing nitrobenzene. The concentration of nitrobenzene in the wastewater is 500 mg / L, and the pH value is 7.0. The inner diameter of the supergravity reactor packing is 0.4 m, the outer diameter is 0.75 m, and the rotation speed is 1200 rpm. Add divalent iron chelating agent to wastewater, the active ingredient is soluble iron salt with a ferrous iron concentration of 1g / L, and an iron salt chelating agent with a concentration of 2g / L, and the soluble iron salt is FeSO 4 ·7H 2 O, the iron salt chelating agent is ethylenediaminetetraacetic acid (EDTA), the ozone mixed gas flow rate is 75 L / h, the ozone concentration is 60 mg / L, and the liquid-gas ratio is 440 L / m 3 , add 10mL of ferrous iron chelating agent per liter of waste water. The waste water was recycled for 30 minutes, the content of nitrobenzene in the waste water was 1.4 mg / L, the removal rate of nitrobenzene reached 99%, and th...

Embodiment 2

[0029] Example 2: Using figure 1 The process shown is to treat waste water containing p-nitrophenol, the concentration of p-nitrophenol in the waste water is 300 mg / L, and the pH value is 8.0. The inner diameter of the supergravity reactor packing is 30 cm, the outer diameter is 60 cm, and the rotation speed is 900 rpm. Add a divalent iron chelating agent to the wastewater, the active ingredient is a soluble iron salt with a ferrous iron concentration of 8g / L, an iron salt chelating agent with a concentration of 10g / L, and the soluble iron salt is FeSO 4 ·7H 2 O, the iron salt chelating agent is ethylenediaminetetraacetic acid (EDTA), the ozone mixed gas flow rate is 75 L / h, the ozone concentration is 80 mg / L, and the liquid-gas ratio is 340 L / m 3 15mL of ferrous iron chelating agent is added per liter of waste water. The waste water was recycled for 25 minutes, and the removal rate of p-nitrophenol in the waste water reached 96%, and the removal rate of COD was 85%. Under...

Embodiment 3

[0030] Example 3: Using figure 1 The process shown is to treat wastewater containing 2,4-dinitrotoluene (2,4-DNT), with a pH value of 9.0. The concentration of 2,4-DNT in wastewater was 400 mg / L. The inner diameter of the supergravity reactor packing is 0.4 m, the outer diameter is 0.75 m, and the rotation speed is 500 rpm. Add divalent iron chelating agent to wastewater, the active ingredient is soluble iron salt with ferrous iron concentration of 3g / L, iron salt chelating agent with concentration of 5g / L, soluble iron salt is FeSO 4 ·7H 2 O, the iron salt chelating agent is ethylenediaminetetraacetic acid (EDTA), the ozone concentration in the ozone mixed gas is 100 mg / L, and the liquid-gas ratio is 240 L / m 3 , add 20mL of ferrous iron chelating agent per liter of waste water. The wastewater was recycled for 35 minutes, and the removal rate of 2,4-DNT in the wastewater was 95%, and the removal rate of COD was 90%. Under the same operating conditions, the removal rate of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com